Preparation method and application of dual-functional hydrodeoxygenation catalyst

A deoxygenation catalyst and dual-function technology, applied in the field of preparation of dual-function hydrodeoxygenation catalysts, to achieve the effect of improving catalytic activity and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

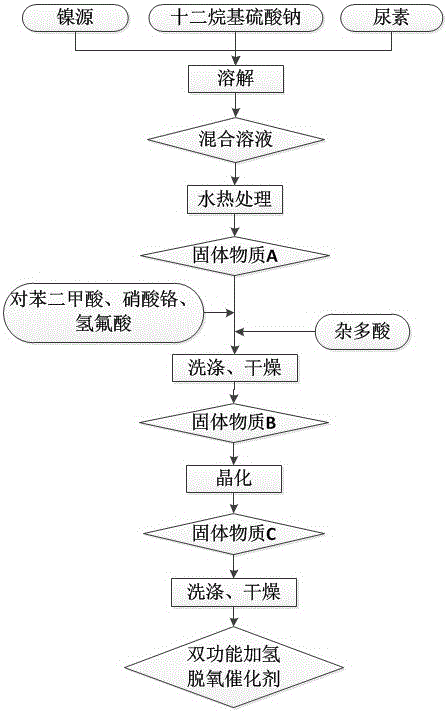

[0022] A preparation method and application of a dual-functional hydrodeoxygenation catalyst of the present invention, specifically comprising the following steps:

[0023] (1) Weigh sodium lauryl sulfate and dissolve it in deionized water to make a solution with a mass concentration of 3%, then add nickel source with a mass concentration of 5%, then add urea with a mass concentration of 3%, and continue stirring After 8 minutes, a mixed solution was formed after dissolution.

[0024] The nickel source described in step (1) is nickel nitrate.

[0025] (2) After hydrothermally treating the mixed solution in step (1) at a temperature of 180°C for 5 hours, take out and filter to obtain solid substance A; then wash solid substance A three times with deionized water and absolute ethanol in turn, and carry out Filtration to obtain solid substance B; finally, dry solid substance B at a temperature of 110° C. for 3 hours to obtain dried solid substance B.

[0026](3) Put the dried s...

Embodiment 2

[0031] A preparation method and application of a dual-functional hydrodeoxygenation catalyst of the present invention, specifically comprising the following steps:

[0032] (1) Weigh sodium lauryl sulfate and dissolve it in deionized water to make a solution with a mass concentration of 5%, then add nickel source with a mass concentration of 10%, then add urea with a mass concentration of 5%, and continue stirring After 10 min, a mixed solution was formed after dissolution.

[0033] The nickel source described in step (1) is nickel chloride.

[0034] (2) After hydrothermally treating the mixed solution in step (1) at a temperature of 220°C for 10 h, take out and filter to obtain solid substance A; then wash solid substance A 4 times with deionized water and absolute ethanol in turn, and carry out Filtration to obtain solid substance B; finally, dry solid substance B at a temperature of 140° C. for 1 hour to obtain dried solid substance B.

[0035] (3) Put the dried solid sub...

Embodiment 3

[0040] A preparation method and application of a dual-functional hydrodeoxygenation catalyst of the present invention, specifically comprising the following steps:

[0041] (1) Weigh sodium lauryl sulfate and dissolve it in deionized water to make a solution with a mass concentration of 1%, then add nickel source with a mass concentration of 1%, then add urea with a mass concentration of 1%, and continue stirring After 5 minutes, a mixed solution was formed after dissolution.

[0042] The nickel source described in step (1) is nickel acetate.

[0043] (2) After hydrothermally treating the mixed solution in step (1) at a temperature of 130°C for 10 h, take out and filter to obtain solid substance A; then wash solid substance A twice with deionized water and absolute ethanol in sequence, and carry out Filtration to obtain solid substance B; finally, dry solid substance B at a temperature of 80° C. for 5 hours to obtain dried solid substance B.

[0044] (3) Put the dried solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com