Preparation method of shape-controlled zinc hydroxide fluoride nano material and application thereof in photocatalysis field

A technology of zinc hydroxide fluoride and nanomaterials, applied in chemical instruments and methods, zinc halide, nanotechnology, etc., to achieve obvious catalytic activity, environmental protection, and mild reaction conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a zinc fluoride hydroxide nanomaterial with controllable morphology, comprising the following steps:

[0029] Step 1, dissolve 0.66g of zinc nitrate and 0.82g of ammonium fluoride in 70ml of water, and stir well;

[0030] Step 2, adding 0.176g of sodium hydroxide, adjusting the pH to 8 to obtain the first mixed solution;

[0031] Step 3: Transfer the first mixed solution to a 100ml polytetrafluoroethylene liner, seal it, heat it with water at 100°C, and after 6 hours, wash, dry and grind to obtain the zinc hydroxide fluoride nanomaterial.

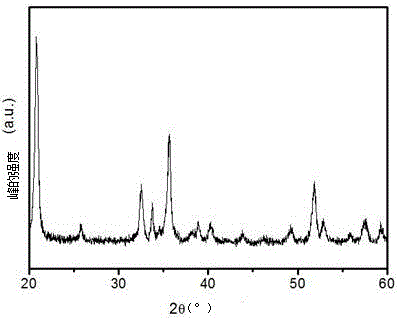

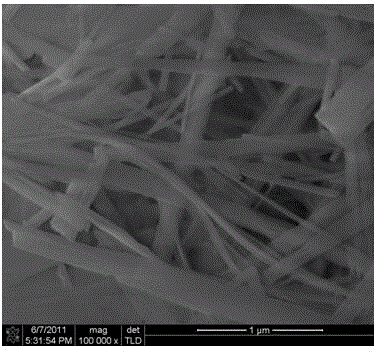

[0032] Characterize the zinc hydroxide nanomaterial prepared in Example 1 of the present invention, the results are as follows figure 1 and figure 2 shown. in, figure 1 It is the XRD spectrum pattern of the zinc hydroxide nanomaterial obtained in Example 1. Compared with the standard card, all the diffraction peaks in the diffraction pattern correspond to the ZnOHF material well; figure 2 This is the SEM...

Embodiment 2

[0034] A method for preparing zinc fluoride hydroxide nanomaterials with controllable morphology is the same as in Example 1, except that 0.66g of zinc nitrate and 0.82g of ammonium fluoride are dissolved in 50ml of deionized water and 20ml of methanol in step 1; 3 in a water bath for 8 hours.

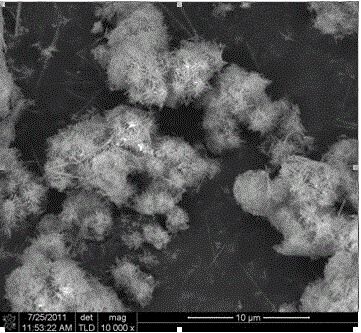

[0035] Such as image 3 As shown, the ZnOHF nanomaterial prepared in Example 2 of the present invention is composed of a large number of circular network ZnOHF.

Embodiment 3

[0037] A method for preparing zinc fluoride hydroxide nanomaterials with controllable morphology is the same as in Example 2, except that in step 1, 0.66 g of zinc nitrate and 0.82 g of ammonium fluoride are dissolved in 50 ml of deionized water and 20 ml of ethanol.

[0038] Such as Figure 4 As shown, the ZnOHF nanomaterial prepared in Example 3 of the present invention is composed of a large number of nanorod-shaped ZnOHF.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com