Method for pretreating wastewater in industrial zone based on coupling oxidation of catalyzed iron reduction and application thereof

An industrial park, catalytic iron technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. The effect of improving the biodegradability of wastewater, low solid waste disposal cost, and low solid waste generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

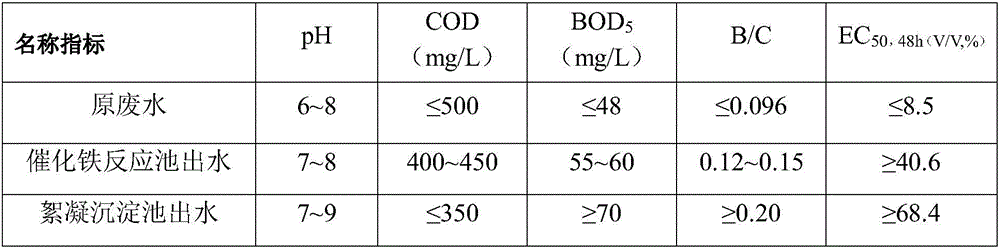

[0037]An industrial park in Jiangsu is mainly a printing and dyeing and fine chemical enterprise. 3 / d design, the wastewater has the characteristics of high bioinhibition toxicity, poor biodegradability, and large fluctuations in water quality. The specific raw wastewater quality is shown in Table 1. After pretreatment, the wastewater enters the subsequent biochemical and advanced treatment units, and the final treated effluent meets the standard and is discharged to natural water bodies.

[0038] 1) The industrial wastewater in the park is first collected into the wastewater regulating tank. The residence time of the regulating tank is 24 hours. The perforated tube is used to aerate and stir for homogenization, and the pH in the tank is controlled to be 6.5-8.5.

[0039] 2) The waste water in the adjustment pool is lifted to the catalytic iron reduction pool by the pump, and the filler in the pool is copper-plated iron shavings, and the copper plating rate is 0.15% (mass rat...

Embodiment 2

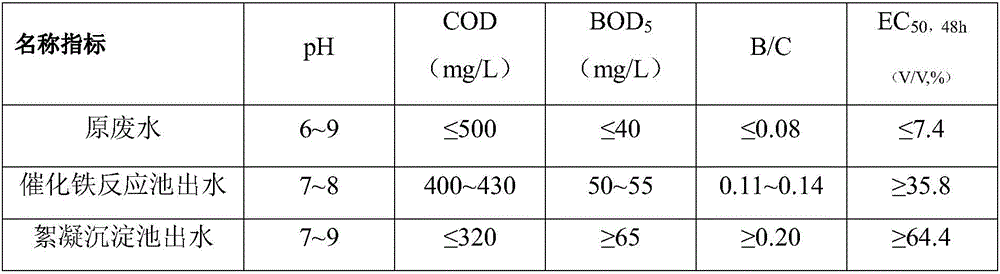

[0047] A certain chemical industry park in Jiangsu is mainly pharmaceutical, dyestuff and chemical enterprises. 3 / d design, the wastewater has the characteristics of high bioinhibition toxicity, poor biodegradability, and large fluctuations in water quality. The specific raw wastewater quality is shown in Table 2. After pretreatment, the wastewater enters the subsequent biochemical and advanced treatment units, and is discharged to natural water bodies after the final treatment reaches the standard.

[0048] 1) The industrial wastewater in the park is first collected into the wastewater regulating tank. The residence time in the regulating tank is 24 hours. It is homogenized by perforating and stirring, and the pH in the tank is controlled at 6.5-8.5.

[0049] 2) The wastewater from the adjustment pool is pumped up to the catalytic iron reduction pool. The filler in the pool is copper-plated iron shavings, and the copper plating rate is 0.25%. (Mass ratio) The preparation me...

Embodiment 3

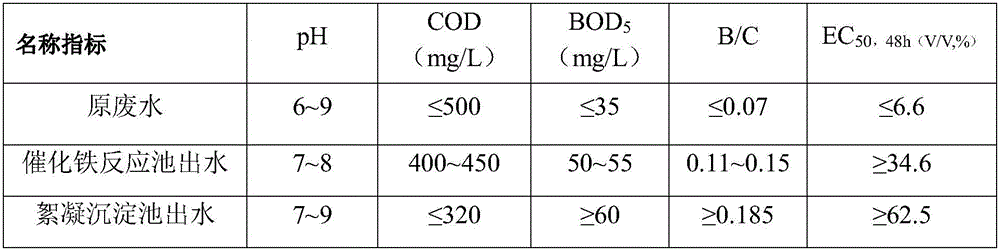

[0057] An industrial park in Jiangsu is mainly pharmaceutical, pesticide, and chemical companies. The pretreatment volume of wastewater in the park in the embodiment of the present invention is based on 20000m 3 / d design, the wastewater has the characteristics of high bioinhibitory toxicity, poor biodegradability, and large fluctuations in water quality. The specific raw wastewater quality is shown in Table 3. After pretreatment, the wastewater enters the subsequent biochemical and advanced treatment units, and the final treated effluent meets the standard and is discharged to natural water bodies.

[0058] 1) The industrial wastewater in the park is first collected into the wastewater regulating tank. The residence time in the regulating tank is 24 hours. It is homogenized by perforating and stirring, and the pH in the tank is controlled at 6.5-8.5.

[0059] 2) The wastewater from the adjustment pool is pumped to the catalytic iron reduction pool, and the filler in the pool ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com