Technique for co-production of dimethyl carbonate and oxamide

A technology of dimethyl carbonate and process method, which is applied in the field of organic catalytic synthesis, can solve the problems of low utilization rate of ammonia gas, increase of equipment and process cost, and decrease of reaction equilibrium constant, so as to avoid the increase of process and equipment cost and improve Atom economy, the effect of avoiding inefficiency loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

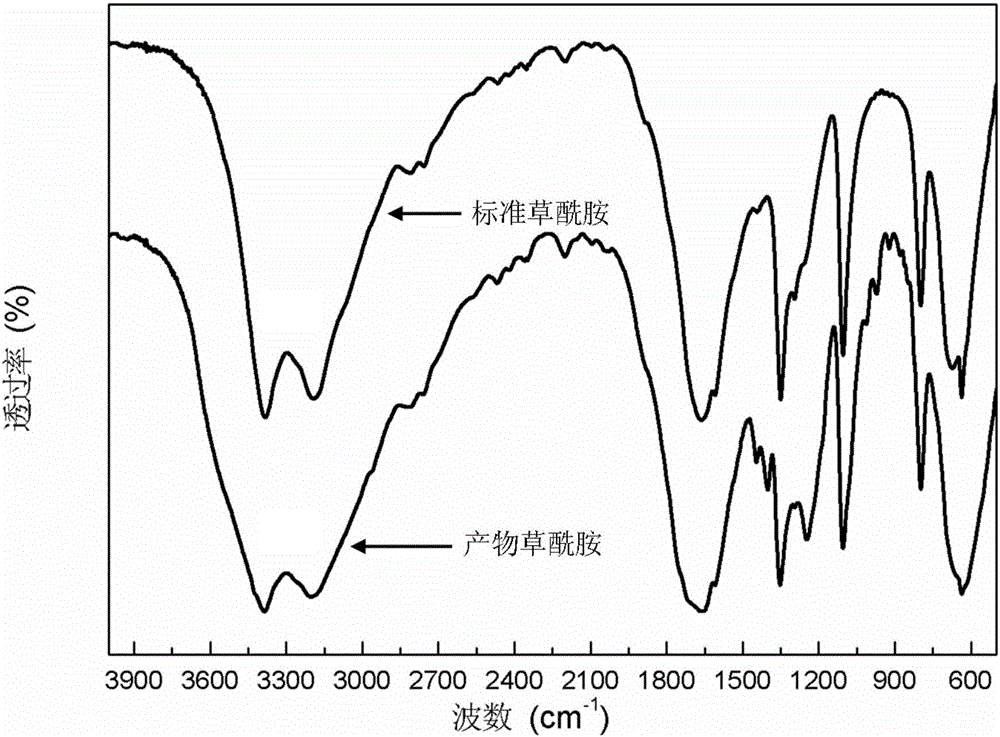

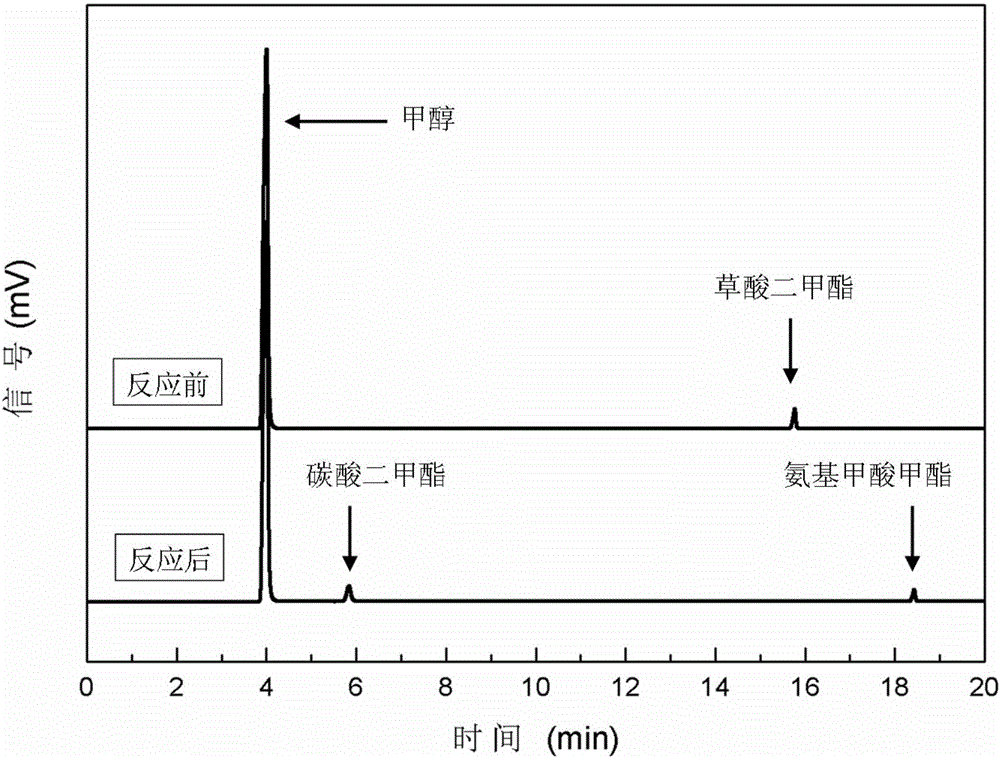

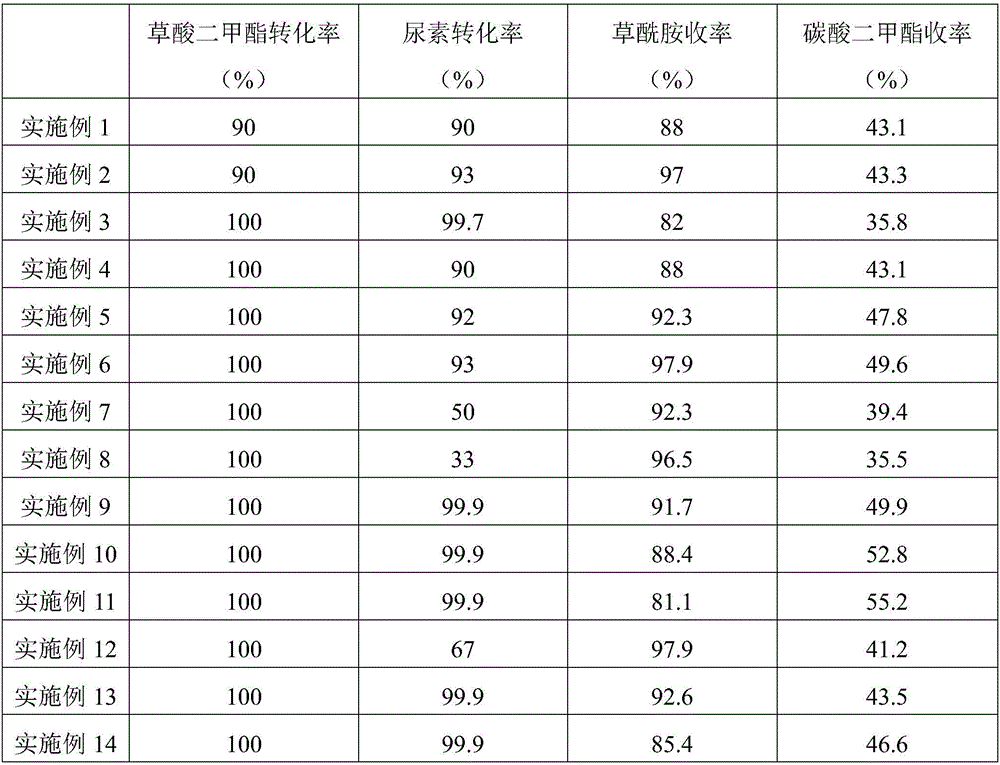

Embodiment 1

[0025] Weigh 11.8g of dimethyl oxalate, 6g of urea, and 6.4g of anhydrous methanol and fill them into a stirred autoclave. The molar ratio of methanol, urea, and dimethyl oxalate is 2:1:1. Then weigh 1g CuO / CaO-In 2 o 3 -CdO catalyst is loaded into the reactor, the mass ratio of catalyst and dimethyl oxalate is 8.5%, CuO accounts for 50% of the total mass of the catalyst in the catalyst, CaO accounts for 5% of the total mass of the catalyst, In2 o 3 It accounts for 40% of the total mass of the catalyst, and CdO accounts for 10% of the total mass of the catalyst. Access to N 2 After the air in the kettle was replaced, the pressure was increased to 1 MPa, the temperature was raised to 70° C. and the temperature was continuously stirred at 100 rpm for 1 hour. Then the temperature was raised to 150° C., and the reaction was continued for 5 h at a stirring speed of 100 rpm. Finally, turn off the heating. After the temperature in the reactor drops to room temperature, open the g...

Embodiment 2

[0029] With embodiment 1, difference is that reaction pressure is 3MPa. The product analysis results are shown in Table 1.

Embodiment 3

[0031] Same as Example 1, except that the reaction temperature is 180°C. The product analysis results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com