Oxa-trimethylene (FeFe) hydrogenase active center model compound containing monophosphine ligand and synthesizing method thereof

A technology of hydrogenase activity and synthesis method is applied in the field of oxiliene [iron iron] hydrogenase active center model substances and the synthesis field thereof, which can solve the problems of low catalytic hydrogen release performance and the like, and achieves simple, easy to operate, mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

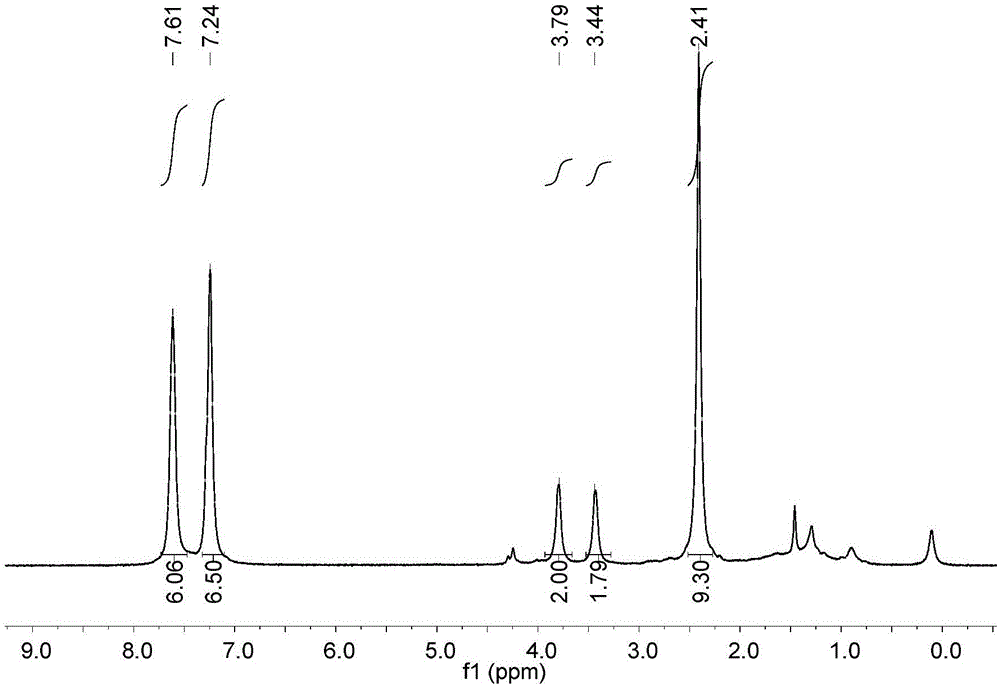

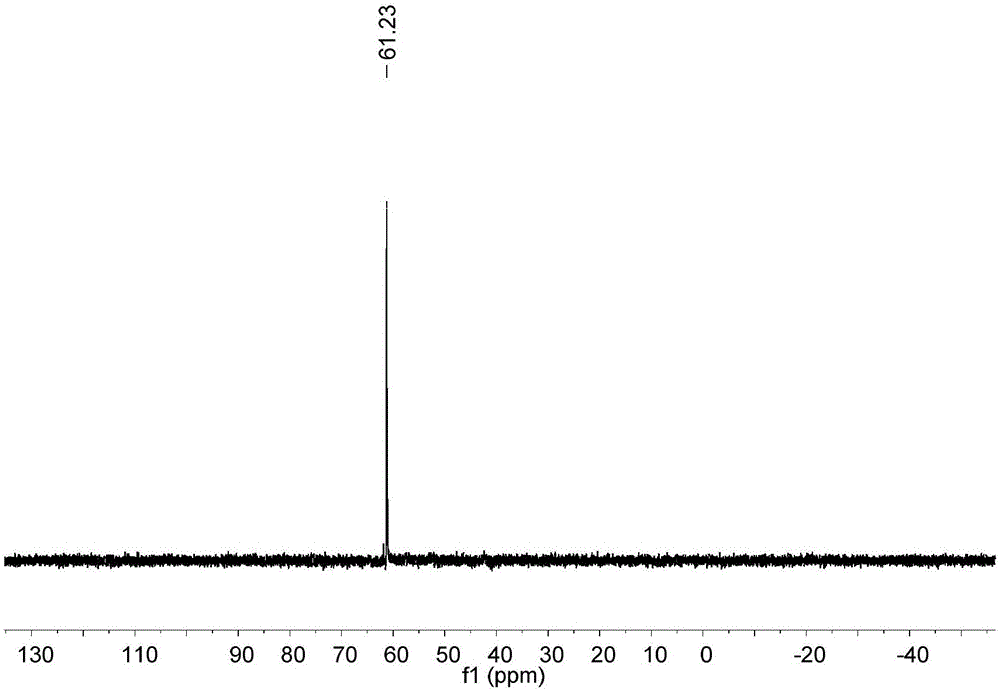

[0034] A kind of synthetic method of oxirane (ODT) type [iron iron] hydrogenase active center model object 1 containing monophosphine ligand, the chemical formula of described model object 1 is Fe 2 [(SCH 2 ) 2 O](CO) 5 [P(C 6 h 4 -4-CH 3 ) 3 ], its chemical synthesis process is as follows:

[0035]

[0036] Concrete synthetic steps are as follows:

[0037] Under nitrogen protection conditions, add 344mg Fe 2 S 2 (CO) 6 (1mmol) and 15mL of tetrahydrofuran solvent to obtain a deep red solution, the resulting solution was cooled to -75°C with a liquid nitrogen bath, and 2mL of lithium triethylborohydride (1Min THF) solution was slowly added under stirring conditions, and after 15min of reaction , add 0.18mL trifluoroacetic acid (2mmol), continue to react after 15min, add 0.2mL formaldehyde solution (37%wt), the reaction system is raised to room temperature, after stirring for 2h, add 304mg of P(C 6 h 4 -4-CH 3 ) 3 (1mmol), after stirring at room temperature for ...

Embodiment 2

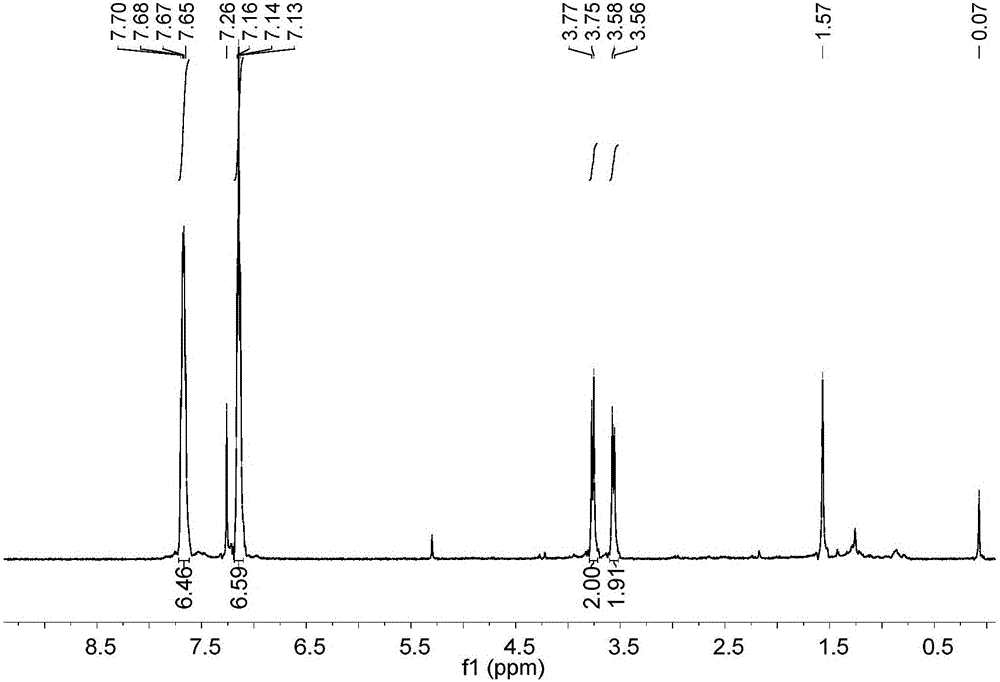

[0042] A kind of synthetic method of oxirane (ODT) class [iron iron] hydrogenase active center model object 2 containing monophosphine ligand, the chemical formula of described model object 2 is Fe 2 [(SCH 2 ) 2 O](CO) 5 [P(C 6 h 4 -4-F) 3 ], its chemical synthesis process is as follows:

[0043]

[0044] Concrete synthetic steps are as follows:

[0045] Under the protection condition of argon gas, add 344mg Fe in the flask equipped with stirring magnet 2 S 2 (CO) 6 (1mmol) and 15mL of tetrahydrofuran solvent to obtain a deep red solution, the resulting solution was cooled to -78°C with a liquid nitrogen bath, and 2mL of lithium triethylborohydride (1M in THF) solution was slowly added under stirring conditions, and reacted for 10min Afterwards, 0.18 mL of trifluoroacetic acid was added, and after continuing the reaction for 15 min, 0.18 mL of formaldehyde solution (37% wt) was added, the reaction system was raised to room temperature, and 320 mg of P(C 6 h 4 -4-...

Embodiment 3

[0050] A method for synthesizing an oxapropylene class [iron iron] hydrogenase active center model substance 3 containing a monophosphine ligand, the chemical formula of the model substance 3 being Fe 2 [(SCH 2 ) 2 O](CO) 5 (Ph 2 PCH 2 CH 3 ), and its chemical synthesis process is as follows:

[0051]

[0052] Concrete synthetic steps are as follows:

[0053] Under the condition of nitrogen gas protection, add 344mg Fe in the flask equipped with stirring magnet 2 S 2 (CO) 6 (1mmol) and 20mL of tetrahydrofuran solvent to obtain a deep red solution, the resulting solution was cooled to -80°C with a liquid nitrogen bath, and 2.2mL of lithium triethylborohydride (1M in THF) solution was slowly added under stirring conditions, and the reaction After 15 minutes, add 0.2 mL of trifluoroacetic acid, continue the reaction for 10 minutes, add 0.2 mL of formaldehyde solution (37% wt), raise the reaction system to room temperature, stir for 2 hours, then add 235 mg of Ph 2 PC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com