Method for one-step synthesis of metal oxide loaded transition metal carbide

A technology of transition metals and oxides, which is applied in the direction of carbide, manganese oxide/manganese hydroxide, cobalt oxide/cobalt hydroxide, etc., and can solve the problems of using hydrofluoric acid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

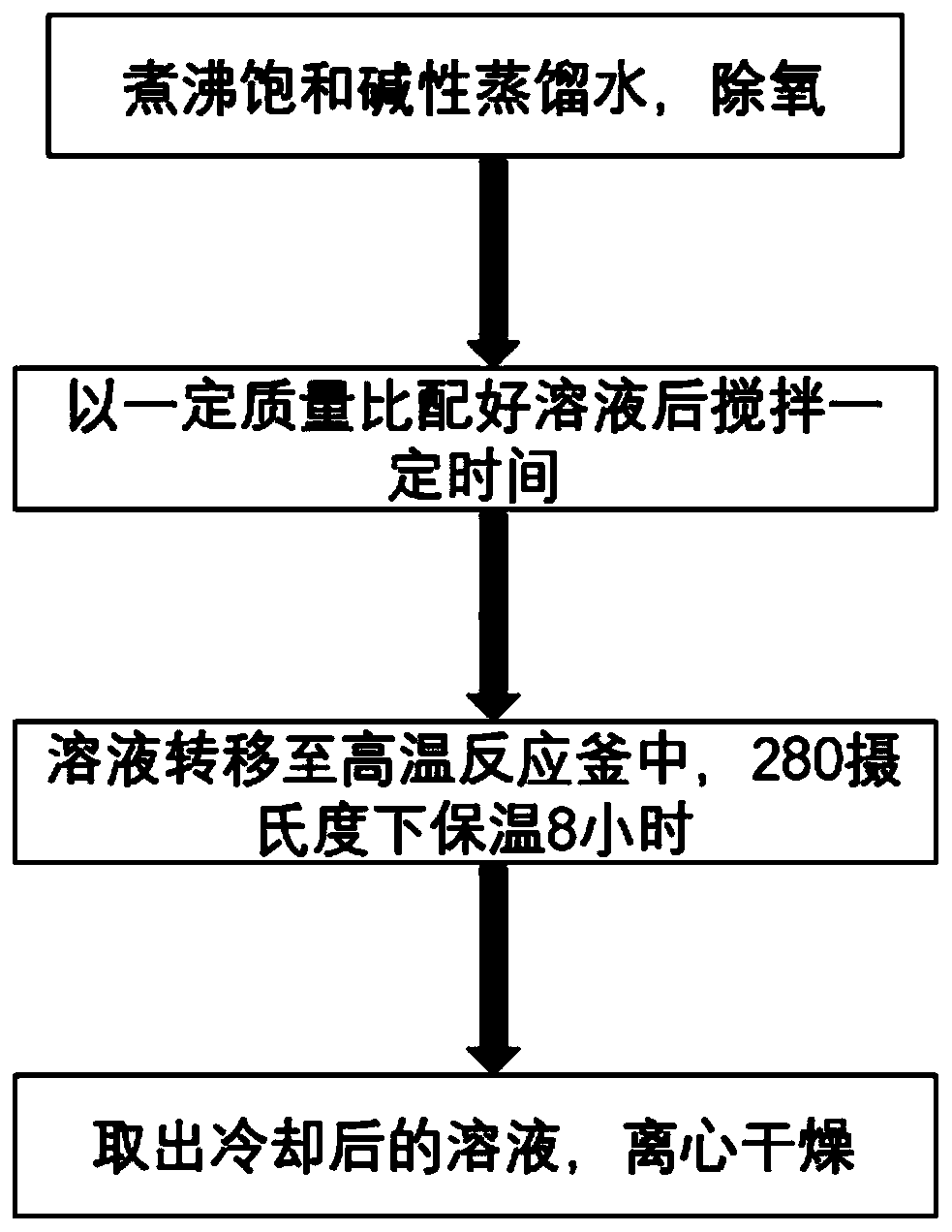

Method used

Image

Examples

Embodiment 1

[0029] Boil distilled water and cool to 60°C, add sodium hydroxide or potassium hydroxide to make a saturated alkaline solution, then add the raw material MAX (Ti 3 AlC 2 , Ti 2 AlC, etc.), metal oxide precursors (iron acetylacetonate, cobalt acetylacetonate, manganese acetylacetonate, etc.), hydrazine hydrate, in every 100mL of saturated alkaline solution, add 1g MAX phase, 0.5g metal oxide precursor (acetylacetonate Iron acetonate, cobalt acetylacetonate, manganese acetylacetonate, etc.), 1mL hydrazine hydrate (mass fraction: 80%), magnetically stirred for 30min, transferred the solution to a high-temperature reaction kettle, raised the temperature to 280°C, and placed it in a muffle furnace for 8h , the solution was taken out and centrifuged, washed with water until the pH of the solution was about 7, and then dried in vacuum for later use.

Embodiment 2

[0031] Boil distilled water and cool to 60°C, add sodium hydroxide or potassium hydroxide to make a saturated alkaline solution, then add the raw material MAX (Ti 3 AlC 2 , Ti 2 AlC, etc.), metal oxide precursors (iron acetylacetonate, cobalt acetylacetonate, manganese acetylacetonate, etc.), hydrazine hydrate, in every 100mL of saturated alkaline solution, add 1g MAX phase, 1g metal oxide precursor (acetylacetonate Iron, cobalt acetylacetonate, manganese acetylacetonate, etc.), 2mL hydrazine hydrate (mass fraction is 80%), magnetically stirred for 30min, transferred the solution to a high-temperature reaction kettle, raised the temperature to 280°C, and placed it in a muffle furnace for 8h. The solution was taken out and centrifuged, washed with water until the pH of the solution was about 7, dried in vacuum and then used for later use.

Embodiment 3

[0033] Boil distilled water and cool to 60°C, add sodium hydroxide or potassium hydroxide to make a saturated alkaline solution, then add the raw material MAX (Ti 3 AlC 2 , Ti 2 AlC, etc.), metal oxide precursors (iron acetylacetonate, cobalt acetylacetonate, manganese acetylacetonate, etc.), hydrazine hydrate, in every 100mL of saturated alkaline solution, add 1g MAX phase, 1.5g metal oxide precursor (acetylacetonate Iron acetonate, cobalt acetylacetonate, manganese acetylacetonate, etc.), 3mL hydrazine hydrate (mass fraction: 80%), magnetically stirred for 30min, transferred the solution to a high-temperature reaction kettle, raised the temperature to 280°C, and placed it in a muffle furnace for 8h , the solution was taken out and centrifuged, washed with water until the pH of the solution was about 7, and then dried in vacuum for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com