Special decolorization resin for starch saccharification liquid

A technology of starch saccharification solution and decolorization resin, applied in the direction of coating, can solve the problems of increasing decolorization cycle and cost investment, and achieve the effect of shortening processing cycle, good reproducibility and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of the water phase: first add 6 parts of chlorinated polyethylene, 5 parts of squash gum and 1 part of agar powder to 250 parts of water, heat to 60-65 °C and mix for 15 minutes, then add 4 parts of water-soluble shell Polysaccharide and 3 parts of anionic polyacrylamide, continue to reflux and mix for 15 minutes, the resulting mixture is cooled to -5-0°C within 5 minutes under an ice-salt bath, and kept at -5-0°C for 2 hours, and finally in the homogeneous Carry out two homogenizations at a homogenization temperature of 65-70°C and a homogenization pressure of 20-25 MPa to obtain an aqueous phase solution;

[0025] (2) Preparation of oil phase: first heat 20 parts of divinylbenzene and 15 parts of porogen to 75-80 ° C and mix for 15 minutes, then add 70 parts of styrene and 45 parts of hydroxyethyl methacrylate, and mix thoroughly Then microwave at a microwave frequency of 2450MHz and a power of 700W for 5 minutes, and then continue to microwave for 5 m...

Embodiment 2

[0031] (1) Preparation of the water phase: first add 8 parts of chlorinated polyethylene, 4 parts of squash gum and 1 part of agar powder to 300 parts of water, heat to 60-65 °C and mix for 15 minutes, then add 6 parts of water-soluble shell Polysaccharide and 3 parts of anionic polyacrylamide, continue to reflux and mix for 15 minutes, the resulting mixture is cooled to -5-0°C within 5 minutes under an ice-salt bath, and kept at -5-0°C for 2 hours, and finally in the homogeneous Carry out two homogenizations at a homogenization temperature of 65-70°C and a homogenization pressure of 20-25 MPa to obtain an aqueous phase solution;

[0032] (2) Preparation of oil phase: first heat 25 parts of divinylbenzene and 15 parts of porogen to 75-80 ° C and mix for 15 minutes, then add 80 parts of styrene and 50 parts of hydroxyethyl methacrylate, and mix thoroughly Then microwave at a microwave frequency of 2450MHz and a power of 700W for 5 minutes, and then continue to microwave for 5 m...

Embodiment 3

[0038] The same batch of starch saccharification liquid was fully mixed and divided into 5 parts on average, and the resins prepared in Examples 1 and 2 of the present invention were used for decolorization treatment, and the decolorization rate was compared with commercially available resins D318, DM-301 and AB-8. Determination, the results are shown in Table 1.

[0039] The decolorization effect of the resin made by table 1 embodiment 1 and 2

[0040] project Example 1 Example 2 D318 DM-301 AB-8 Decolorization rate 98.8% 98.5% 91.2% 92.4% 91.8%

[0041] It can be seen from Table 1 that the decolorization effect of the resins prepared in Examples 1 and 2 of the present invention on starch saccharification liquid is stronger than that of the commercially available resins D318, DM-301 and AB-8, and the decolorization rate reaches more than 98%.

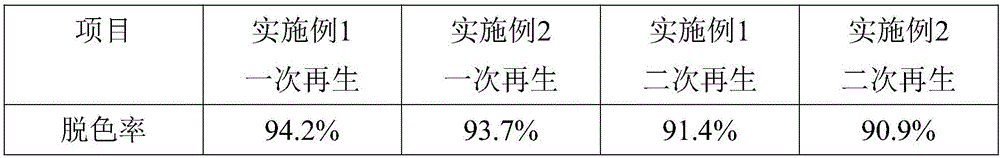

[0042] The resins produced in Examples 1 and 2 of the present invention were regenerated twice, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com