Radiation-proof thermal control coating and manufacturing method thereof

A thermal control coating and radiation protection technology, which is applied to radiation-absorbing coatings, coatings, and radiation protection devices for aerospace vehicles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

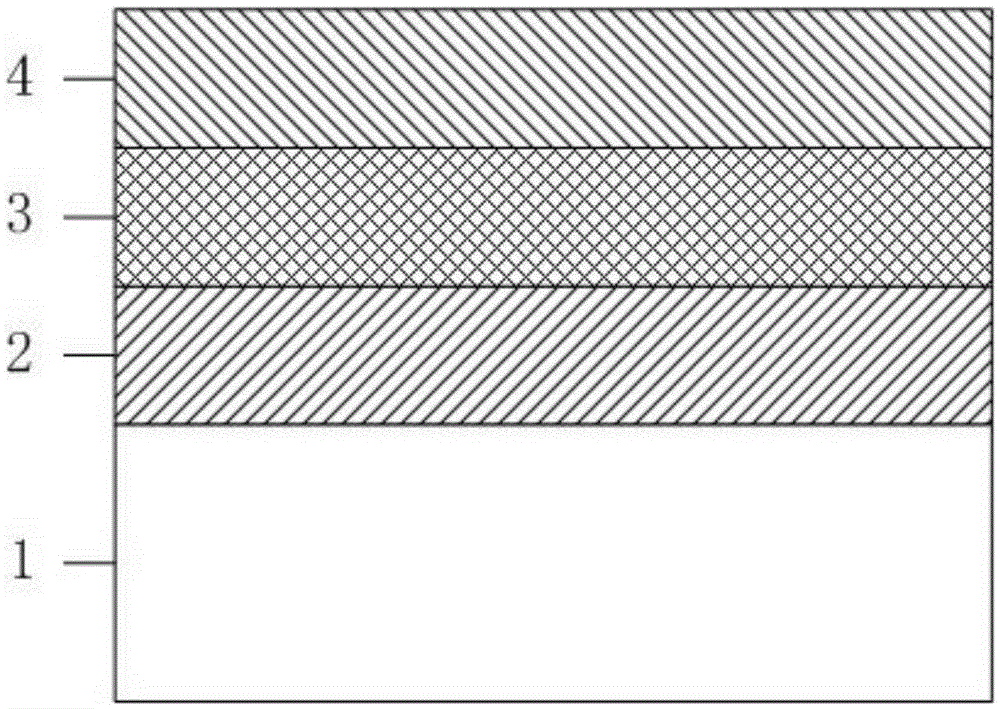

[0027] Example 1 ZrO2 bottom layer, ZnO middle layer, BN surface coating

[0028] After mixing the zirconia particles and the silicone resin binder according to the weight ratio of 1:2, spray on the Al 2 o 3 On the substrate, spray the thickness of 0.1mm, and cure for 12 hours; then mix zinc oxide particles and silicone resin adhesive according to the weight ratio of 1:2, spray on the substrate, spray the thickness of 0.1mm, and cure for 16 hours; finally nitrogen After the boron oxide particles and the silicone resin adhesive are uniform according to the weight ratio of 1:2, they are sprayed on the substrate with a spray thickness of 0.1mm, and after curing for 24 hours, the coating is completed.

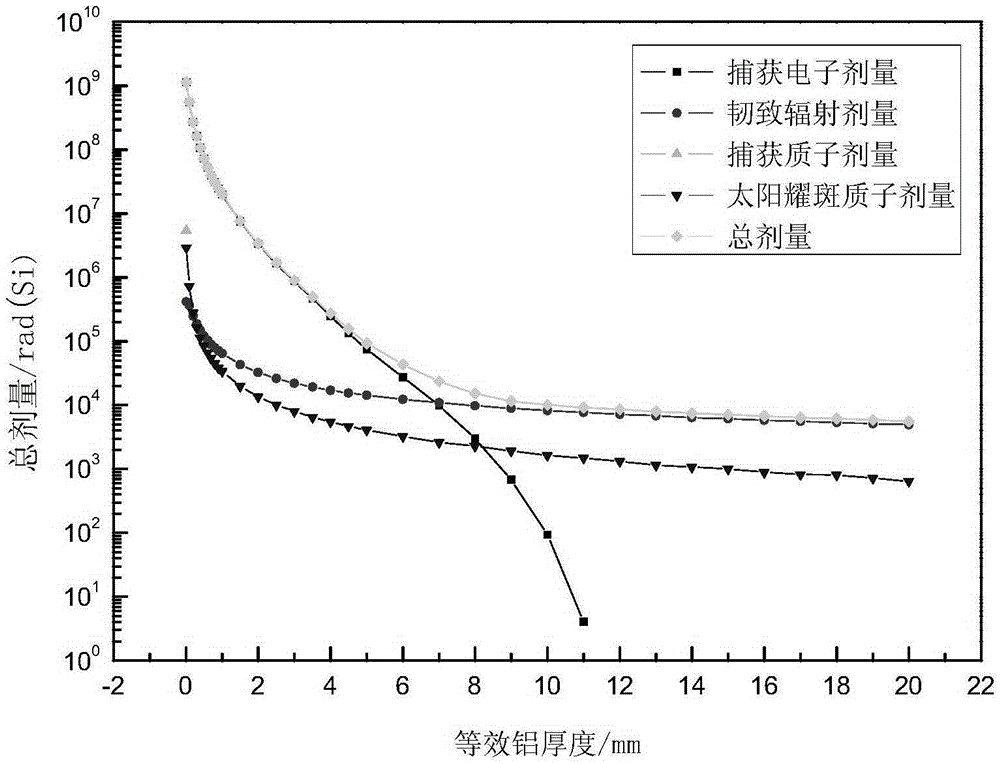

[0029] After measurement, the measured solar absorption ratio αs is about 0.152, and the thermal emissivity ε is about 0.886, which is equivalent to ZnO white paint and S781 white paint. Using Casino electron incident simulation software to calculate, under the same surface d...

Embodiment 2

[0030] Example 2 BaO bottom layer, ZnO middle layer, BN surface coating

[0031] After mixing the barium oxide particles and the silicone resin binder according to the weight ratio of 1:4, spray on the SiO 2 On the substrate, spray the thickness of 0.3mm, and cure for 16 hours; then mix zinc oxide particles and silicone resin adhesive according to the weight ratio of 1:4, spray on the substrate, spray the thickness of 0.3mm, and cure for 20 hours; finally nitrogen After the boron oxide particles and the silicone resin adhesive are uniform according to the weight ratio of 1:4, they are sprayed on the substrate with a spray thickness of 0.05mm, and after curing for 24 hours, the coating is completed.

[0032] After measurement, the measured solar absorption ratio αs is about 0.150, and the thermal emissivity ε is about 0.891, which is equivalent to ZnO white paint and S781 white paint. Using Casino electron incident simulation software to calculate, under the same surface den...

Embodiment 3

[0033] Example 3 Bi 2 O 3 Bottom layer, TiO 2 Intermediate layer, BN surface coating

[0034] After mixing the bismuth oxide particles and the silicone resin binder according to the weight ratio of 2:1, spray on the SiO 2 On the substrate, spray coating with a thickness of 0.5mm, and cure for 16 hours; then mix titanium oxide particles and silicone resin binder uniformly according to the weight ratio of 1:2, spray on the substrate, spray with a thickness of 0.5mm, and cure for 20 hours; finally nitrogen After the boron oxide particles and the silicone resin adhesive are uniform according to the weight ratio of 1:2, they are sprayed on the substrate with a spray thickness of 0.3mm, and after curing for 24 hours, the coating is completed.

[0035] After measurement, the measured solar absorption ratio αs is about 0.155, and the thermal emissivity ε is about 0.881, which is equivalent to ZnO white paint and S781 white paint. Using Casino electron incident simulation so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com