Anaerobic adhesive and preparation method thereof

An anaerobic adhesive and epoxy acrylate technology, which is applied in the field of industrial adhesives, can solve the problems of short storage time of anaerobic adhesives, and achieve the effect of low raw material cost and high storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

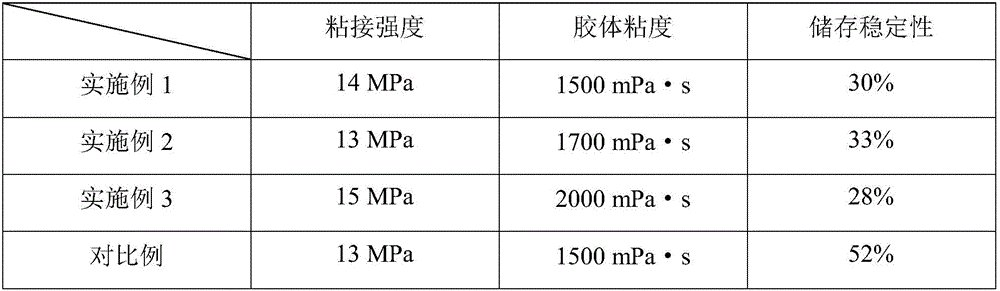

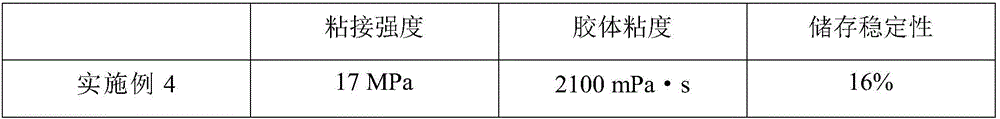

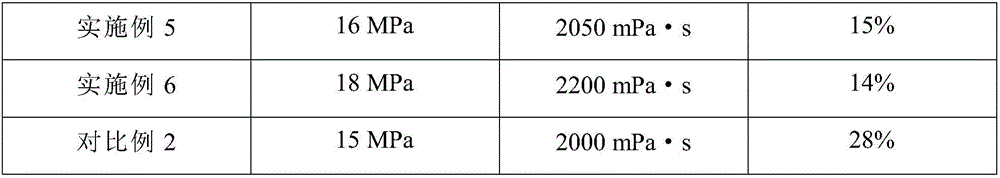

Examples

Embodiment 1

[0027] An anaerobic adhesive, consisting of the following raw materials in parts by weight: 20 parts of hydroxyethyl methacrylate, 8 parts of polyurethane acrylate, 8 parts of epoxy acrylate, 40 parts of precipitated silica, and 4 parts of thixotropic agent , 1 part of hydroxyethyl acrylate, 1 part of trimethylolpropane triacrylate, 0.1 part of acrylic acid, 1 part of cumene hydroperoxide, 1 part of N,N-dimethylaniline, o-benzoylsulfonyl 0.3 part of amine, 0.5 part of polymerization inhibitor, 0.1 part of coupling agent and 0.01 part of disodium edetate.

[0028] The thixotropic agent is BYK-410, the polymerization inhibitor is polymerization inhibitor 510, and the coupling agent can be silane coupling agent KH550 or one of calcium carbonate or aluminum silicate.

[0029] The hydroxyethyl methacrylate, urethane acrylate, epoxy acrylate, precipitated silica, thixotropic agent, hydroxyethyl acrylate, trimethylolpropane triacrylate, acrylic acid and cumene of the above parts by w...

Embodiment 2

[0031] An anaerobic adhesive, consisting of the following raw materials in parts by weight: 25 parts of hydroxyethyl methacrylate, 15 parts of polyurethane acrylate, 12 parts of epoxy acrylate, 45 parts of precipitated silica, and 5 parts of thixotropic agent , 2 parts of hydroxyethyl acrylate, 1.5 parts of trimethylolpropane triacrylate, 0.3 parts of acrylic acid, 3 parts of cumene hydroperoxide, 3 parts of N,N-dimethylaniline, o-benzoylsulfonyl 0.8 part of amine, 1 part of polymerization inhibitor, 0.5 part of coupling agent and 0.05 part of disodium edetate.

[0032] The thixotropic agent is BYK-410, the polymerization inhibitor is polymerization inhibitor 510, and the coupling agent can be silane coupling agent KH550 or one of calcium carbonate or aluminum silicate.

[0033] The hydroxyethyl methacrylate, urethane acrylate, epoxy acrylate, precipitated silica, thixotropic agent, hydroxyethyl acrylate, trimethylolpropane triacrylate, acrylic acid and cumene of the above par...

Embodiment 3

[0035] An anaerobic adhesive, consisting of the following raw materials in parts by weight: 23 parts of hydroxyethyl methacrylate, 12 parts of polyurethane acrylate, 10 parts of epoxy acrylate, 43 parts of precipitated silica, and 4.5 parts of thixotropic agent , 1.5 parts of hydroxyethyl acrylate, 1.25 parts of trimethylolpropane triacrylate, 0.2 parts of acrylic acid, 2 parts of cumene hydrogen peroxide, 2 parts of N,N-dimethylaniline, o-benzoylsulfonyl 0.5 part of amine, 0.7 part of polymerization inhibitor, 0.3 part of coupling agent and 0.03 part of disodium edetate.

[0036] The thixotropic agent is BYK-410, the polymerization inhibitor is polymerization inhibitor 510, and the coupling agent can be silane coupling agent KH550 or one of calcium carbonate or aluminum silicate.

[0037] The hydroxyethyl methacrylate, urethane acrylate, epoxy acrylate, precipitated silica, thixotropic agent, hydroxyethyl acrylate, trimethylolpropane triacrylate, acrylic acid, cumene of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com