Composite phase change cold storage material for cold storage and preservation

A cold storage material and composite phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of storing cold energy without too much contribution, reducing the latent heat of phase change of raw materials, and corrosive containers. Achieve the effect of simple processing, no complicated preparation process and ideal refrigeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1: A composite phase-change cold storage material for refrigeration and preservation

[0020] Its raw materials: 1% sorbitol, 0.05% borax, and the rest is water.

[0021] During preparation, sorbitol, borax, and water are sequentially weighed according to the mass percentages of the above-mentioned components. Pour the three into a container and mix, and stir with a glass rod at the same time, until it is even, let it stand for 2-5 minutes.

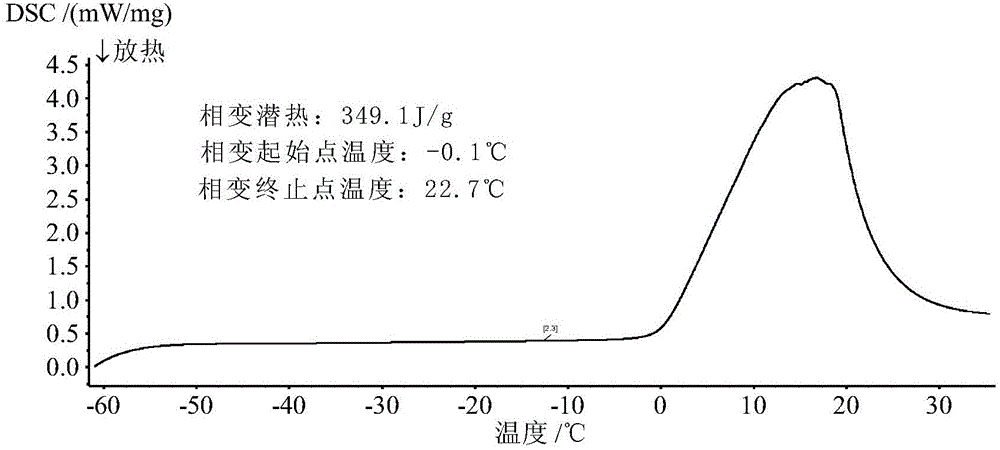

[0022] Such as figure 1 The phase change temperature of the composite phase change cold storage material shown is -0.1°C, and the latent heat of phase change is 349.1 J / g.

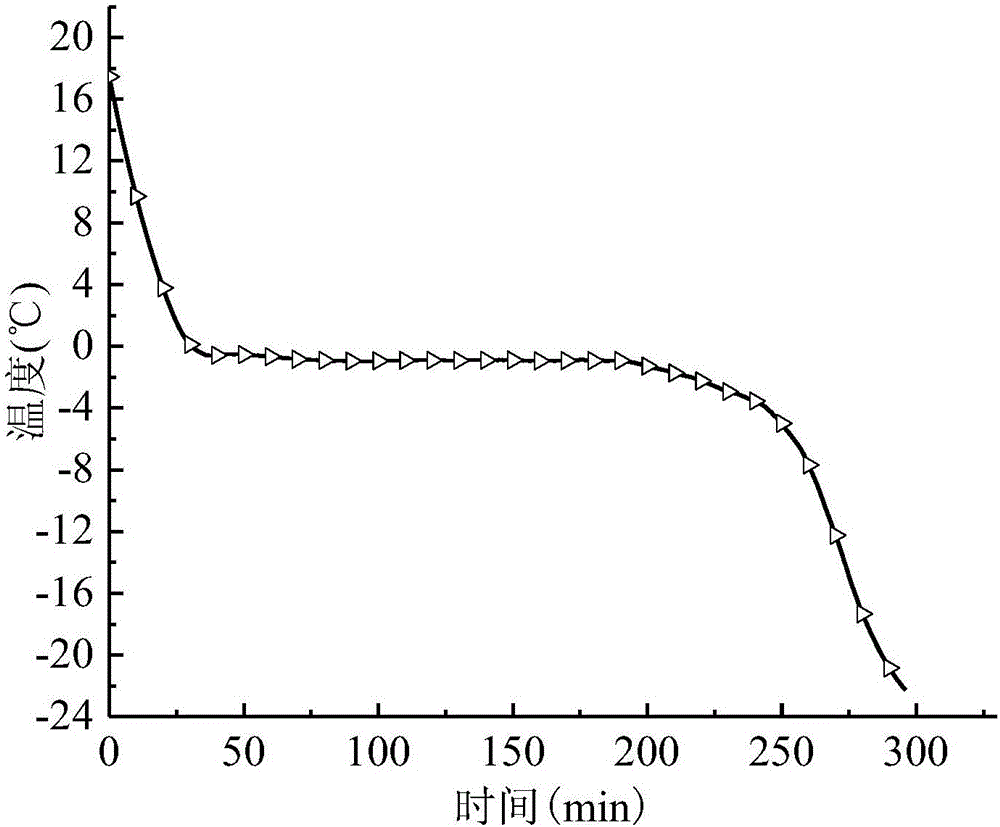

[0023] Such as figure 2 The T-t curve of the composite phase change cold storage material shown has almost no degree of supercooling.

Embodiment 2

[0025] The invention relates to a composite phase-change cold storage material for cold storage and preservation. The mass percent content of each component is as follows: 2% of sorbitol, 0.04% of borax, and the rest is water.

[0026] The phase change temperature of the composite phase change cold storage material is -1.5°C--0.1°C, and the latent heat of phase change is 325J / g-376.1J / g.

[0027] The sorbitol, borax and water are poured into a container and mixed, stirred until uniform, and left to stand for 2-5 minutes.

Embodiment 3

[0029] The invention relates to a composite phase-change cold storage material for cold storage and preservation. The mass percent content of each component is as follows: 1.9%, 0.02% of borax, and the rest is water.

[0030] The phase change temperature of the composite phase change cold storage material is -1.5°C--0.1°C, and the latent heat of phase change is 325J / g-376.1J / g.

[0031] Pour the sorbitol, borax, and water into a container and mix them, and at the same time stir them with a glass rod until they are uniform, then let them stand for 5 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com