Corrosion inhibition pretreatment filming agent and preparing method and application

A pre-filming agent and corrosion-inhibiting technology, which is applied in the coating process of metal materials, etc., can solve problems such as unsatisfactory inhibition of metal corrosion, and achieve excellent oxygen removal effects, prevent impacts, and have no risk of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

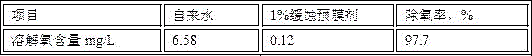

[0024] This embodiment provides a kind of anti-corrosion pre-coating agent, which is composed of the following mass percentages: molybdate 20 kg, phosphate 10 kg, organic phosphonate 2 kg, oxygen scavenger 3 kg, nonionic surfactant 1 kg, 64 kg of water.

[0025] Add the formulated amount of non-ionic surfactant, phosphate, organic phosphonate, and oxygen scavenger in sequence while stirring in the formulated amount of water at 40°C, and stir until completely dissolved to obtain the corrosion inhibitor pre-film agent.

[0026] In this embodiment, the molybdate is ammonium molybdate, the phosphate is disodium hydrogen phosphate, the organic phosphonate is sodium ethylenediamine tetramethylene phosphonate, the oxygen scavenger is carbohydrazide, and the nonionic surfactant is fat Alcohol polyoxyethylene ether AEO-9.

Embodiment 2

[0028] This embodiment provides a kind of anti-corrosion pre-coating agent, which is composed of the following mass percentages: molybdate 20 kg, phosphate 10 kg, organic phosphonate 2 kg, oxygen scavenger 3 kg, nonionic surfactant 1 kg, 64 kg of water.

[0029] Add the formulated amount of non-ionic surfactant, phosphate, organic phosphonate, and oxygen scavenger in sequence while stirring in the formulated amount of water at 60°C, and stir until completely dissolved to obtain the corrosion inhibitor pre-film agent.

[0030] In this embodiment, the molybdate is sodium molybdate, the phosphate is disodium hydrogen phosphate, the organic phosphonate is sodium ethylenediamine tetramethylene phosphonate, the oxygen scavenger is carbohydrazide, and the nonionic surfactant is fat Alcohol polyoxyethylene ether AEO-9.

Embodiment 3

[0032] This embodiment provides a kind of anti-corrosion pre-coating agent, which is composed of the following mass percentages: molybdate 20 kg, phosphate 10 kg, organic phosphonate 2 kg, oxygen scavenger 3 kg, nonionic surfactant 1 kg, 64 kg of water.

[0033] Add the formulated amount of non-ionic surfactant, phosphate, organic phosphonate, and oxygen scavenger in sequence while stirring in the formulated amount of water at 50°C, and stir until completely dissolved to obtain the corrosion inhibitor pre-film agent.

[0034] In this embodiment, the molybdate is sodium molybdate, the phosphate is disodium hydrogen phosphate, the organic phosphonate is sodium ethylenediamine tetramethylene phosphonate, the oxygen scavenger is acetone oxime, and the nonionic surfactant is fatty alcohol Polyoxyethylene ether AEO-9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com