Copper particle, preparation method thereof, paste for forming electric-conductive film, and objects

A manufacturing method and technology of copper particles, applied in the direction of conductive material, conductive material, cable/conductor manufacturing, etc., can solve the problem of increasing process and achieve the effect of reducing the change of resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

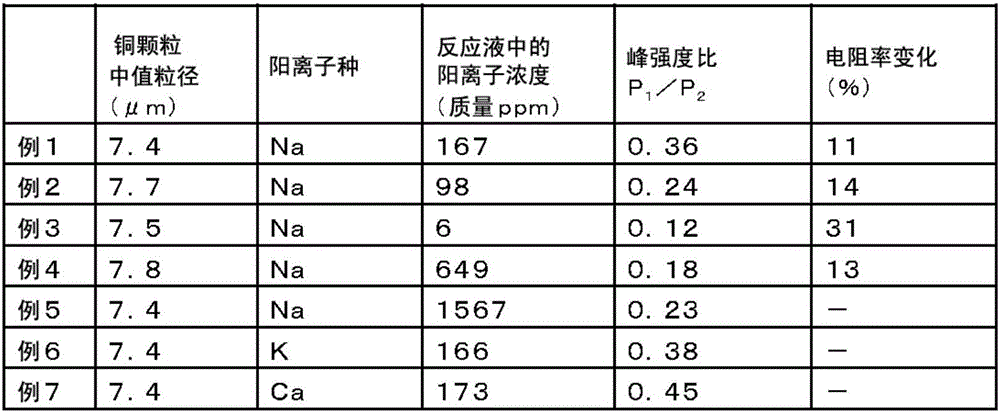

[0075] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. Among the examples shown below, Examples 1, 2, and 4 to 7 are examples, and Example 3 is a comparative example.

[0076] The measurement methods used in each of the following examples are as follows.

[0077] [Median diameter of copper particles]

[0078] A measurement sample was prepared by dispersing 0.2 g of copper particles in a solvent, and measured using LA920 manufactured by HORIBA Corporation as a laser diffraction scattering type particle size distribution analyzer. Ethanol was used as a solvent, and the measurement was performed without applying ultrasonic waves to the measurement sample. The refractive index at the time of measurement is 0.48-2.6 according to the measurement conditions of copper.

[0079] [Peak intensity ratio of diffuse reflectance IR measurement]

[0080] The diffuse reflection IR peak was measured with respect to cop...

example 1

[0084] 764 g of distilled water, 76.2 g of a 76 mass % formic acid aqueous solution, and 99.8 g of a 50 mass % aqueous solution of hypophosphorous acid having a Na concentration of 1500 mass ppm in the aqueous solution were added to a glass beaker so that the Na concentration in the reaction liquid was 167 mass ppm After that, stirring was performed to prepare (pH: 0.7). 100 g of commercially available copper particles (raw material copper particles) (manufactured by Nippon Atomized Metal Powders Corporation, AFS-Cu) was added while stirring the reaction liquid kept at 40° C., and stirred for 60 minutes to perform surface modification treatment. When measuring the fatty acid and / or fatty acid salt bonded to the surface of this raw material copper particle, it was 0.28 mass % in conversion of stearic acid. The bonded amount of fatty acid and / or fatty acid salt is determined by burning the fatty acid and / or fatty acid salt bonded to the surface of raw copper particles with a car...

example 2

[0090] 764 g of distilled water, 76.2 g of a 76 mass % formic acid aqueous solution, 99.8 g of an aqueous hypophosphorous acid solution having a Na concentration of 60 mass ppm and a hypophosphorous acid concentration of 50 mass % in the aqueous solution, and 50 mass / volume % of NaOH were added to a glass beaker. 0.3 mL of the aqueous solution was prepared by stirring the Na concentration in the reaction liquid to 98 mass ppm (pH: 0.7). 100 g of commercially available copper particles (raw material copper particles) (manufactured by Nippon Atomized Metal Powders Corporation, AFS-Cu) were added while stirring the reaction liquid at 40° C., and stirred for 60 minutes to perform surface modification treatment.

[0091] After the surface modification treatment, the copper particles in the reaction solution are precipitated by centrifugation, and the supernatant is removed to separate the precipitate. This precipitate was again dispersed in 30 g of distilled water, and the aggregat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com