Preparation method of lithium nickel manganese oxide serving as high-voltage positive electrode material

A technology of lithium nickel manganate and cathode material, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of high equipment requirements, low energy density, low tap density of lithium nickel manganate materials, etc., and achieve low material cost. , low equipment requirements, inhibiting the effect of rapid nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

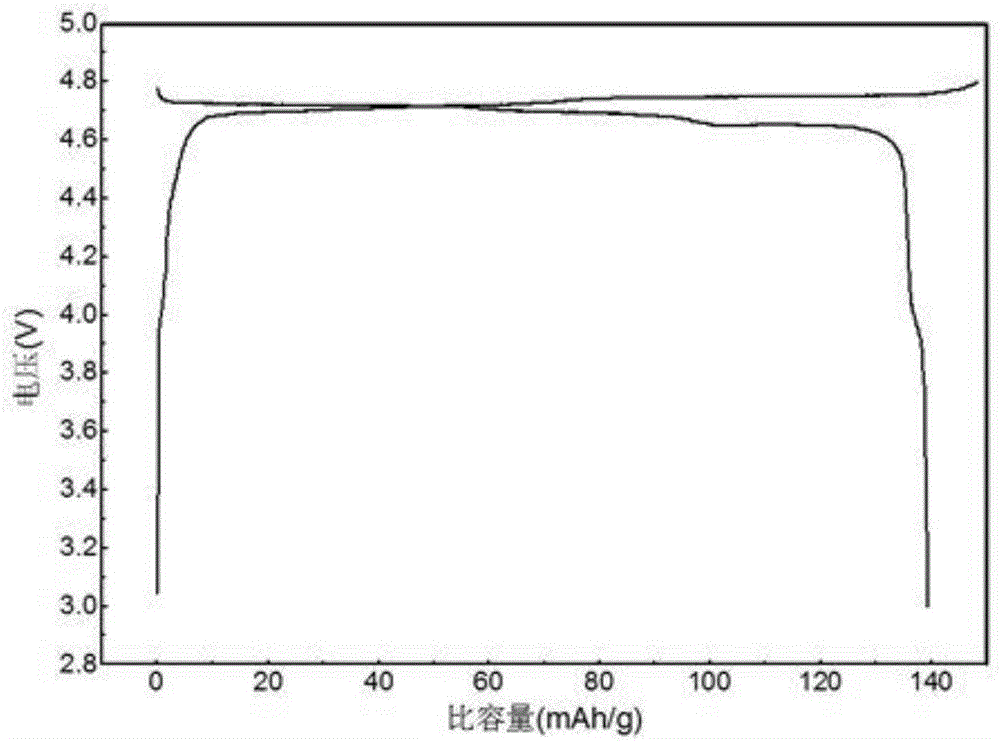

Image

Examples

Embodiment 1

[0023] Accurately weigh nickel sulfate and manganese sulfate according to the molar ratio Ni:Mn=1:3, add an appropriate amount of distilled water to make nickel and manganese mixed salt solution A with a total concentration of 1.5mol / L; 3 2- :C 2 o 4 2- =1:9 Weigh ammonium oxalate and ammonium carbonate, add an appropriate amount of distilled water to prepare a precipitant solution B with a total concentration of 2.0mol / L; add the mixed salt solution A and precipitant solution B to the reaction kettle containing distilled water simultaneously, Under the conditions of a stirring speed of 500r / min and a reaction temperature of 50°C, the pH value of the reaction liquid is adjusted to about 5.0 by controlling the speed of adding ammonium sulfate and precipitant solution B, and washing and drying after 10 hours of reaction to obtain a spherical For the oxalic acid / nickel-manganese carbonate composite precursor, place the precursor in an environment of 500°C for 6 hours, and mix ...

Embodiment 2

[0025] Accurately weigh nickel sulfate and manganese sulfate according to the molar ratio Ni:Mn=1:3, add an appropriate amount of distilled water to make nickel and manganese mixed salt solution A with a total concentration of 2.0mol / L; 3 2- :C 2 o 4 2- =1:8.5 Weigh ammonium oxalate and ammonium carbonate, add an appropriate amount of distilled water to prepare the precipitant solution B with a total concentration of 3.0mol / L; add the mixed salt solution A and the precipitant solution B to the reaction kettle containing distilled water simultaneously, Under the conditions of a stirring speed of 600r / min and a reaction temperature of 50°C, the pH value of the reaction liquid is adjusted to about 5.5 by controlling the speed of adding ammonium sulfate and precipitant solution B, and washing and drying after 15 hours of reaction to obtain a spherical For the oxalic acid / nickel-manganese carbonate composite precursor, place the precursor in an environment of 450°C for 8 hours, ...

Embodiment 3

[0027] Accurately weigh nickel sulfate and manganese sulfate according to the molar ratio Ni:Mn=1:3, add an appropriate amount of distilled water to make nickel and manganese mixed salt solution A with a total concentration of 2.0mol / L; 3 2- :C 2 o 4 2-=1:8 Weigh ammonium oxalate and ammonium carbonate, add an appropriate amount of distilled water to prepare a precipitant solution B with a total concentration of 3.5mol / L; add the mixed salt solution A and precipitant solution B to the reaction kettle containing distilled water simultaneously, Under the conditions of a stirring speed of 750r / min and a reaction temperature of 50°C, the pH value of the reaction liquid is adjusted to about 5.2 by controlling the speed of adding ammonium sulfate and precipitant solution B, and washing and drying after 8 hours of reaction to obtain spherical For the oxalic acid / nickel-manganese carbonate composite precursor, place the precursor in an environment of 550°C for 5 hours, and mix and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com