High-resistance corona-proof belt, and preparation method and application thereof

An anti-corona, high resistance technology, applied in nanotechnology for materials and surface science, winding insulation materials, winding insulation shape/style/structure, etc., can solve the problem that the coating amount cannot be accurately and uniformly distributed and changed The problems of high coating amount and adjustment cost, and high requirements for the cleanliness of the coating environment can achieve the effect of small effective mass, special energy band structure, and no stress and deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

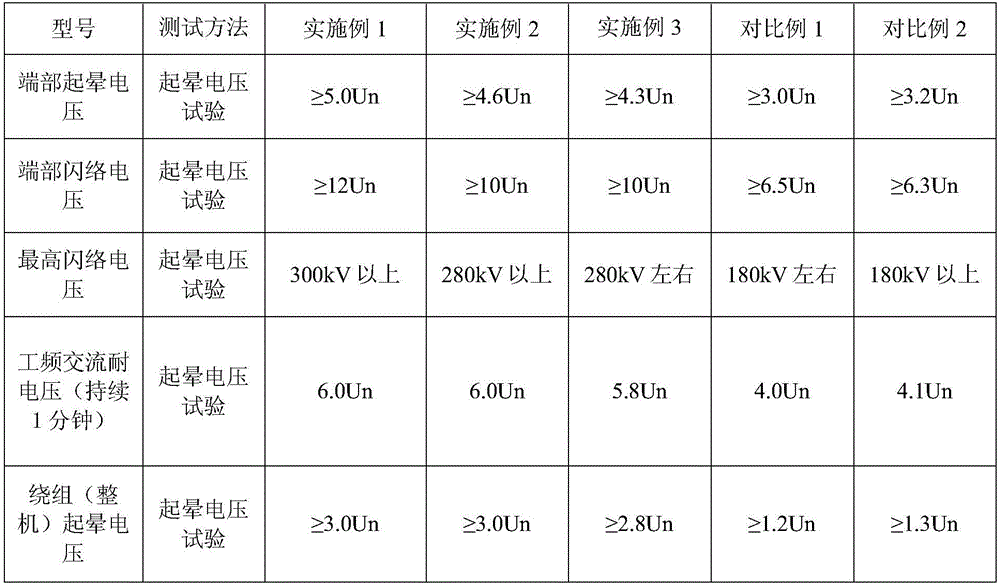

Examples

Embodiment 1

[0043] This embodiment provides a high-resistance anti-corona belt for a high-voltage motor, which is prepared by the following steps:

[0044] (1) Unwinding of the base material, using 0.10±0.02mm×25mm electrical non-alkali glass silk braid;

[0045] (2) The homogeneous precipitation method is used to prepare low-dimensional structure semiconductor materials, that is, ZnO nanomaterials. The specific preparation method is as follows: Zn(NO 3 ) 2 Put it into a NaOH solution with a concentration of 1.0mol / L, heat and stir the reaction, the temperature is controlled at 110°C for reaction, and the stirring speed is controlled at 400rpm. Precipitation occurs after about 2 hours of reaction. After 4 hours, the precipitation is complete, and then the temperature is raised to 350°C for heating. Decomposition reaction, stop heating after 3 hours of reaction, cool down and let stand. Adjust the pH value, filter with suction and repeatedly wash with water until neutral, and dry to obta...

Embodiment 2

[0054] This embodiment provides a high-resistance anti-corona belt for a high-voltage motor, and the high-resistance anti-corona belt is prepared by the following steps:

[0055] (1) The substrate material unwinds, using a 0.10±0.02mm×25mm polyester non-woven tape;

[0056] (2) Zn(NO 3 ) 2 Put it into a NaOH solution with a concentration of 2.0mol / L, heat and stir the reaction, the temperature is controlled at 100°C for reaction, and the stirring speed is controlled at 300rpm. Precipitation occurs after about 2 hours of reaction. After 4 hours, the precipitation is complete, and then the temperature is raised to 400°C for heating. Decomposition reaction, stop heating after 4 hours of reaction, cool down and let stand. Adjust the pH value, filter with suction and repeatedly wash with water until neutral, and dry to obtain ZnO nanomaterials, wherein Zn(NO 3 ) 2 The mass ratio with NaOH is 1:2.

[0057] (3) Heating the ZnO nanomaterials prepared in step (2) into a semi-molte...

Embodiment 3

[0061] This embodiment provides a high-resistance anti-corona belt for high-voltage motors, which is prepared by the following steps:

[0062] (1) Unwinding of the base material, using 0.10±0.02mm×25mm electrical non-alkali glass silk braid;

[0063] (2) Zn(NO 3 ) 2 Put it into a NaOH solution with a concentration of 3.0mol / L, heat and stir the reaction, the temperature is controlled at 120°C for reaction, and the stirring speed is controlled at 300rpm. After about 1 hour of reaction, precipitation appears, and after 4 hours the precipitation is complete, and then the temperature is raised to 300°C Carry out thermal decomposition reaction, stop heating after 3 hours of reaction, cool down and let stand. Adjust the pH value, filter with suction and repeatedly wash with water until neutral, and dry to obtain ZnO nanomaterials, wherein Zn(NO 3 ) 2 The mass ratio to NaOH is 1:3.

[0064] (3) The ZnO nanometer material prepared by step (2) is heated to be melted, and then the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com