Processing method of exocarpium

A processing method and orange-red technology, which is applied in the direction of pharmaceutical formulas, medical preparations containing active ingredients, drug combinations, etc., can solve the problems of high loss of active ingredients, affecting quality, and large product quality differences, and achieve the goal of reducing color changes Probability, prevention of oxidative discoloration, effect of improving drying rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

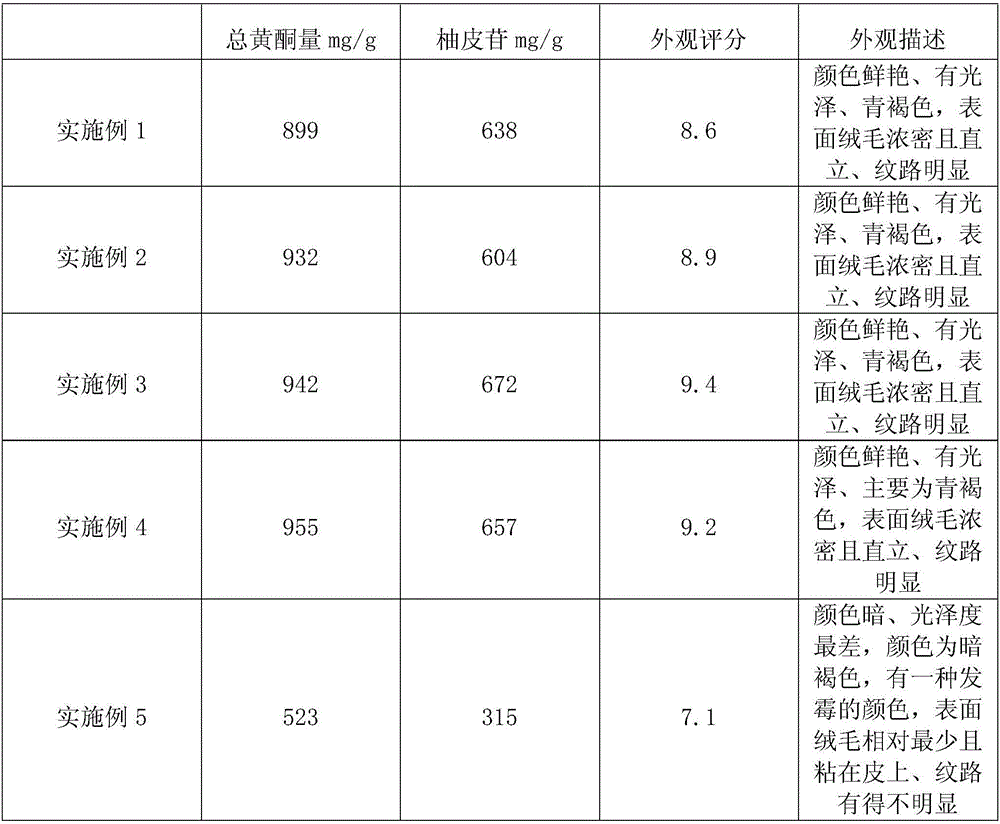

Examples

Embodiment 1

[0034] A processing method for orange red, including the following steps:

[0035] a. Pretreatment and deactivation: After the picked healthy orange and red fruits are washed with acid water, they are taken out and placed in an environment with a saturated steam temperature of 98℃ to deactivate for 30 minutes to obtain deactivation of orange and red fruits;

[0036] Among them, the acid water is selected from citric acid and malic acid, and the ratio of the two is 1:1; the mass percentage concentration of the acid water is 0.3%.

[0037] b. Slicing and pressing: take the cut orange red fruit described in step a and cut into slices with a slicer in a hot air environment, and press the slices according to a conventional process to obtain orange slices;

[0038] Among them, the alkaline water is selected from sodium carbonate; the mass percentage concentration of the alkaline water is 4%.

[0039] Among them, the temperature of the hot air in the hot air environment is 40°C.

[0040] c. Dry...

Embodiment 2

[0044] A processing method for orange red, including the following steps:

[0045] a. Pretreatment and deactivation: After picking the healthy orange and red fruits are washed with acid water, they are taken out and placed in an environment with a saturated steam temperature of 120℃ to deactivate for 5 minutes to obtain deactivation of orange and red fruits;

[0046] Among them, the acid water is selected from malic acid; the mass percentage concentration of the acid water is 1.5%.

[0047] b. Slicing and pressing: take the cut orange red fruit described in step a and cut into slices with a slicer in a hot air environment, and press the slices according to a conventional process to obtain orange slices;

[0048] Among them, the alkaline water is selected from sodium bicarbonate; the mass percentage concentration of the alkaline water is 7%.

[0049] Among them, the temperature of the hot air in the hot air environment is 60°C.

[0050] c. Drying of the orange slices: take the orange slic...

Embodiment 3

[0054] A processing method for orange red, including the following steps:

[0055] a. Pretreatment and curing: After picking the healthy orange and red fruits are washed with acid water, they are taken out and placed in an environment with a saturated steam temperature of 105 ℃ for curing for 20 minutes to obtain the orange and red fruits;

[0056] Among them, the acid water is selected from citric acid; the mass percentage concentration of the acid water is 0.8%.

[0057] b. Slicing and pressing: take the cut orange red fruit described in step a and cut into slices with a slicer in a hot air environment, and press the slices according to a conventional process to obtain orange slices;

[0058] Wherein, the alkaline water is selected from the mixture of sodium bicarbonate and sodium carbonate, the ratio of the mixing of the two is 1:2; the mass percentage concentration of the alkaline water is 5%.

[0059] Among them, the temperature of the hot air in the hot air environment is 50°C.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com