High-efficient phosphate removing agent and preparation method thereof

A kind of phosphorus removal agent and high-efficiency technology, applied in the field of high-efficiency phosphorus removal agent and its preparation, can solve problems such as difficult to achieve, difficult to guarantee phosphorus removal, etc., and achieve the effects of convenient use, excellent phosphorus removal effect, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A high-efficiency phosphorus removal agent, formulated according to the following mass percentages:

[0037] 30kg of metal compounds, including 10kg of aluminum sulfate, 15kg of ferrous sulfate, and 5kg of lanthanum oxide;

[0038] 10kg of natural mineral powder, including 5kg of bentonite, 3kg of attapulgite, and 2kg of diatomite;

[0039] 10kg of flocculant, including 6kg of polyferrosilicate flocculant and 4kg of polyacrylamide;

[0040] Activated carbon 5kg;

[0041] Coagulant aid 5kg, including calcium oxide 2kg, calcium hydroxide 3kg.

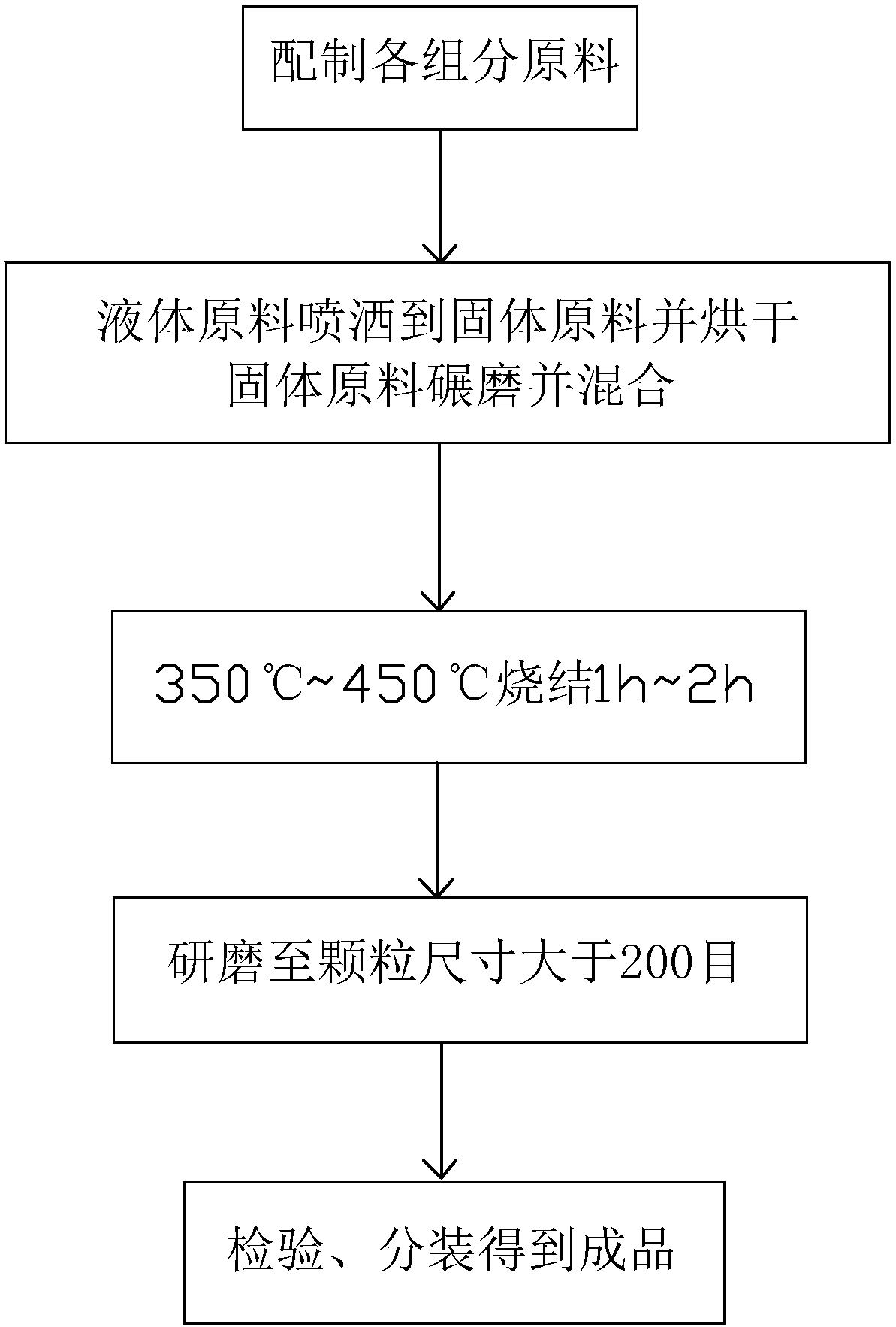

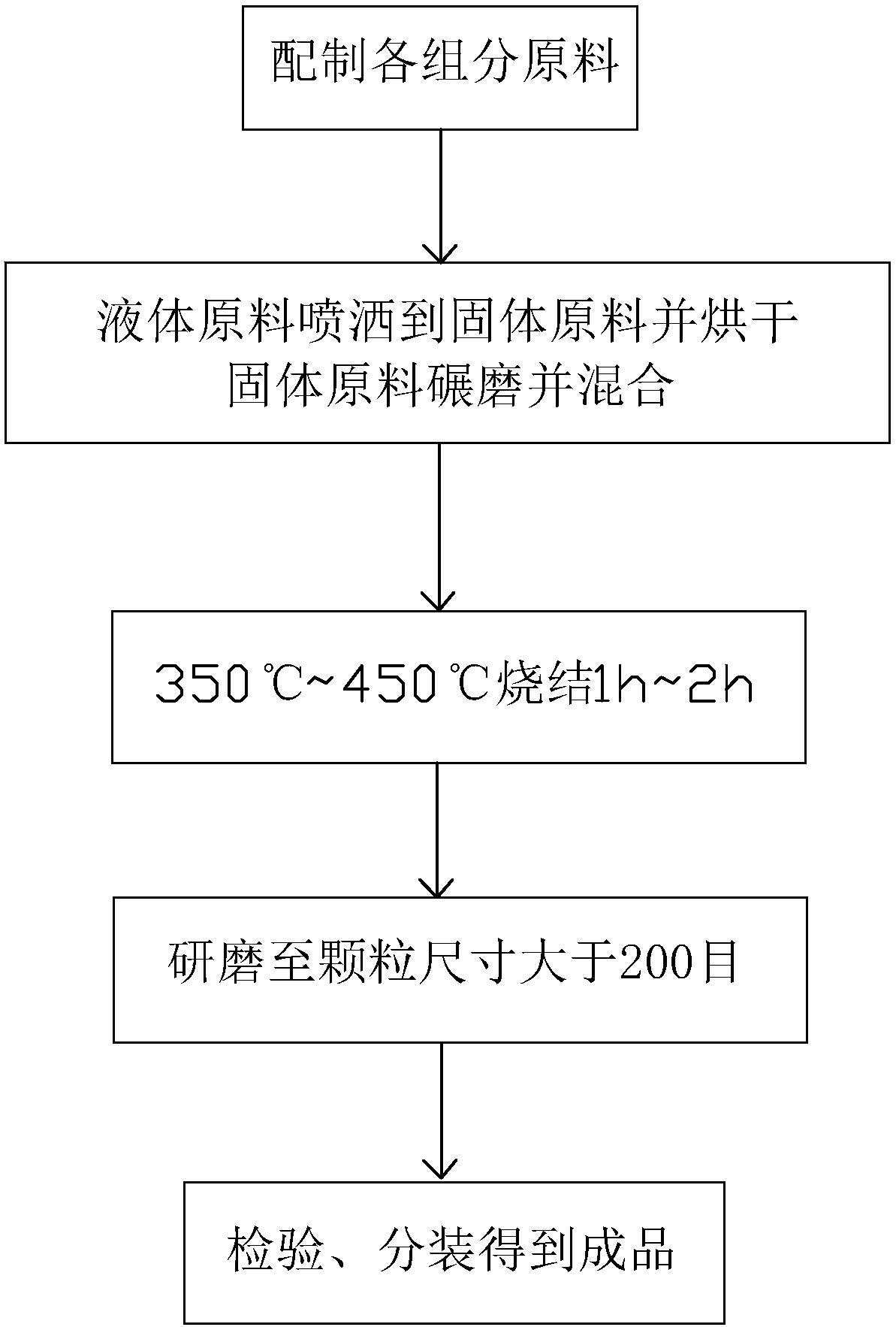

[0042] as per figure 1 The process shown in the preparation of high-efficiency phosphorus removal agent, the specific steps are:

[0043] a. Prepare the raw materials of each component of the high-efficiency phosphorus removal agent according to the above-mentioned mass percentage;

[0044] b. Spray the liquid raw material on the solid raw material and dry it, grind the solid raw material and mix it;

[0045] c. Sinter all the ...

Embodiment 2~ Embodiment 5

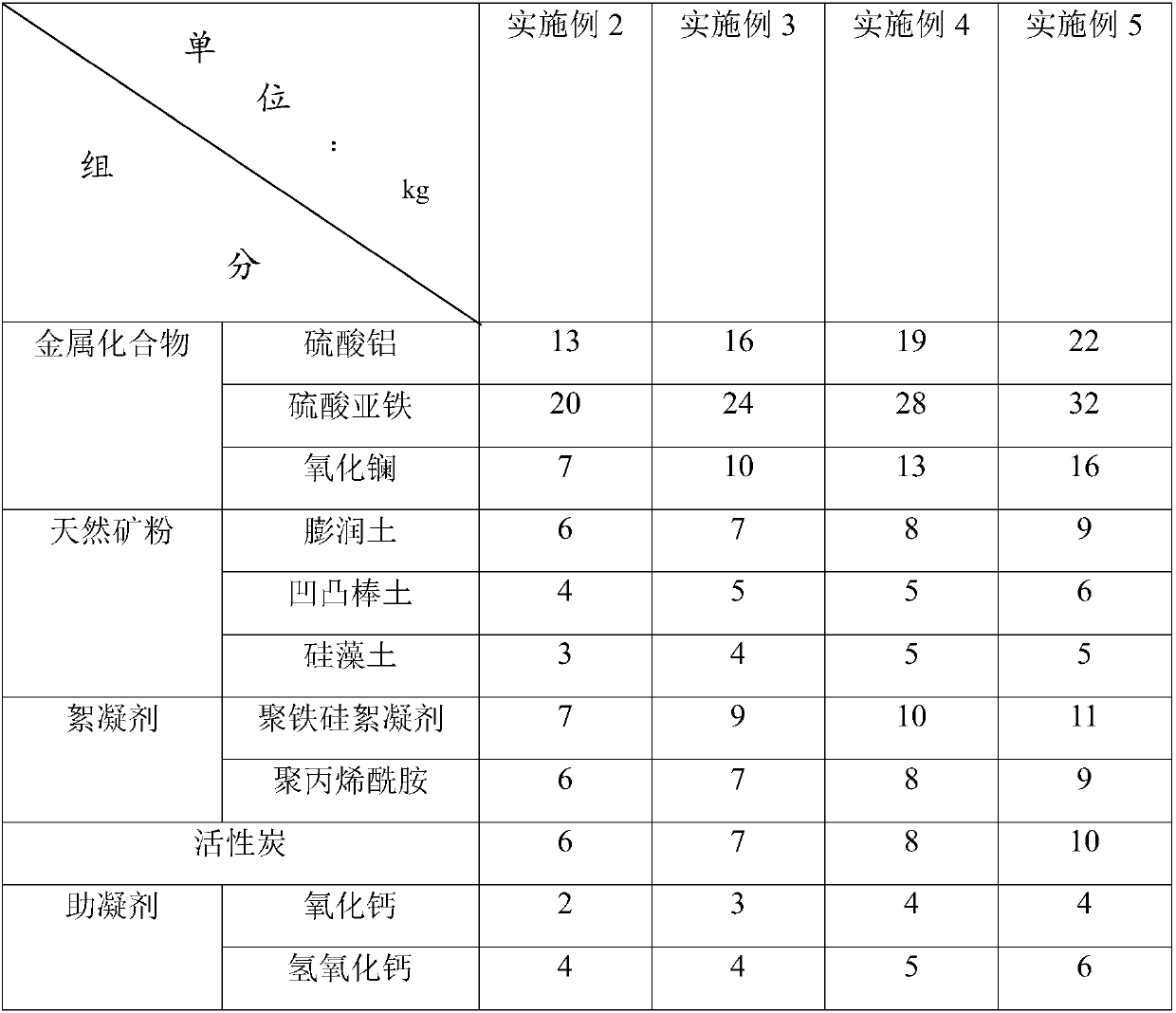

[0049] The difference between Example 2-Example 5 and Example 1 is that the distribution ratio of each component is different, see Table 1 for details.

[0050] The composition distribution ratio of table 1 embodiment 2~embodiment 5

[0051]

[0052] Taking the production sewage of a shelf production plant in Jiangning, Nanjing as a sample, the Juhuihai JX-305 phosphorus removal agent produced by Jiangxi Huihai Environmental Protection Technology Co., Ltd. was selected as a representative of ordinary phosphorus removal agents to discuss the phosphorus removal effect of high-efficiency phosphorus removal agents.

[0053] Take 6000mL of electroplated iron plate water as sewage water sample, and carry out phosphorus content detection and phosphorus removal test in sewage. Determination - ammonium molybdate spectrophotometric method as standard. The total phosphorus content of the sewage water sample was measured to be 21.7 mg / L, and the pH of the raw water was 6.5.

[0054] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com