Brassica juncea pickling waste water treatment device and method

A technology for pickling wastewater and treatment equipment, which is applied in the direction of food industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problem of blocked microbial metabolic enzyme activity, limited application of activated sludge method, and slow biological growth problems such as improved biodegradability, reduced requirements for water distribution uniformity, and low operating energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

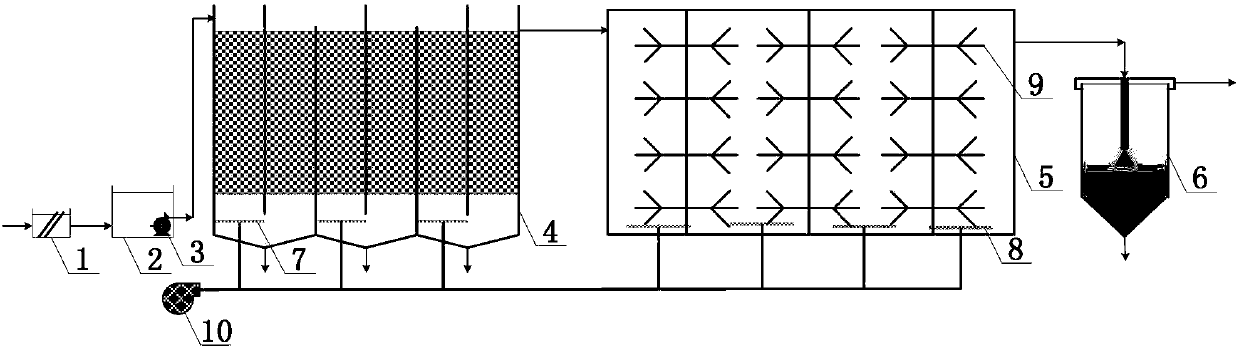

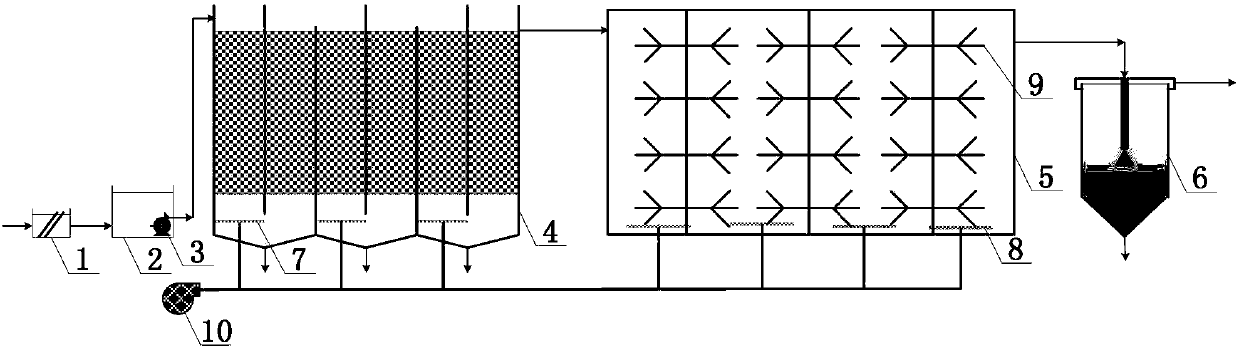

[0075] The water quality of production wastewater in a mustard pickling factory is: salinity (calculated as NaCl): 20-25g / L; COD: 3240-4150mg / L; ammonia nitrogen: 180-230mg / L; total phosphorus: 7.3-8.7mg / L .

[0076] Apply mustard pickling wastewater treatment method of the present invention, comprise the following steps:

[0077] (1) Wastewater enters the sewage collection tank 2 through the grid 1, and the grid 1 is a rotary grid decontamination machine, the grid spacing is 1mm, and the grid series interval is 0.5mm;

[0078] (2) The waste water enters the iron-carbon micro-electrolytic cell 4 under the promotion of the sewage pump 3, and flows through the iron-carbon filler in a baffle type, and the flow velocity is 0.5cm / s;

[0079] (3) The waste water after the iron-carbon micro-electrolysis treatment flows into the biological contact oxidation tank 5 by itself. The biological contact oxidation tank is a rectangular aeration tank with a combined filler inside, the hydrauli...

Embodiment 2

[0084] The water quality of production wastewater in a mustard pickling factory is: salinity (calculated as NaCl): 20-25g / L; COD: 3240-4150mg / L; ammonia nitrogen: 180-230mg / L; total phosphorus: 7.3-8.7mg / L .

[0085] Apply mustard pickling wastewater treatment method of the present invention, comprise the following steps:

[0086] (1) Wastewater enters the sewage collection tank 2 through the grid 1, and the grid 1 is a rotary grid decontamination machine, the grid spacing is 1mm, and the grid series interval is 0.5mm;

[0087] (2) The waste water enters the iron-carbon micro-electrolytic cell 4 under the promotion of the sewage pump 3, and flows through the iron-carbon filler in a baffle type, and the flow rate is 1cm / s;

[0088] (3) The waste water after the iron-carbon micro-electrolysis treatment flows into the biological contact oxidation tank 5 by itself. The biological contact oxidation tank is a rectangular aeration tank with a combined filler inside, the hydraulic re...

Embodiment 3

[0093] The water quality of production wastewater in a mustard pickling factory is: salinity (calculated as NaCl): 20-25g / L; COD: 3240-4150mg / L; ammonia nitrogen: 180-230mg / L; total phosphorus: 7.3-8.7mg / L .

[0094] Apply mustard pickling wastewater treatment method of the present invention, comprise the following steps:

[0095] (1) Wastewater enters the sewage collection tank 2 through the grid 1, and the grid 1 is a rotary grid decontamination machine, the grid spacing is 1mm, and the grid series interval is 0.5mm;

[0096] (2) The waste water enters the iron-carbon micro-electrolytic cell 4 under the promotion of the sewage pump 3, and flows through the iron-carbon filler in a baffle type, and the flow velocity is 1.5cm / s;

[0097] (3) The waste water after the iron-carbon micro-electrolysis treatment flows into the biological contact oxidation tank 5 by itself. The biological contact oxidation tank is a rectangular aeration tank with a combined filler inside. The hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com