Cationic visible light curing composition

A cationic, cationic light-initiated technology, applied in the field of photopolymerization, can solve the problems of poor environmental safety, high curing cost, and limited application, and achieve the effects of low cost, high photocuring conversion rate, and fast initiation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

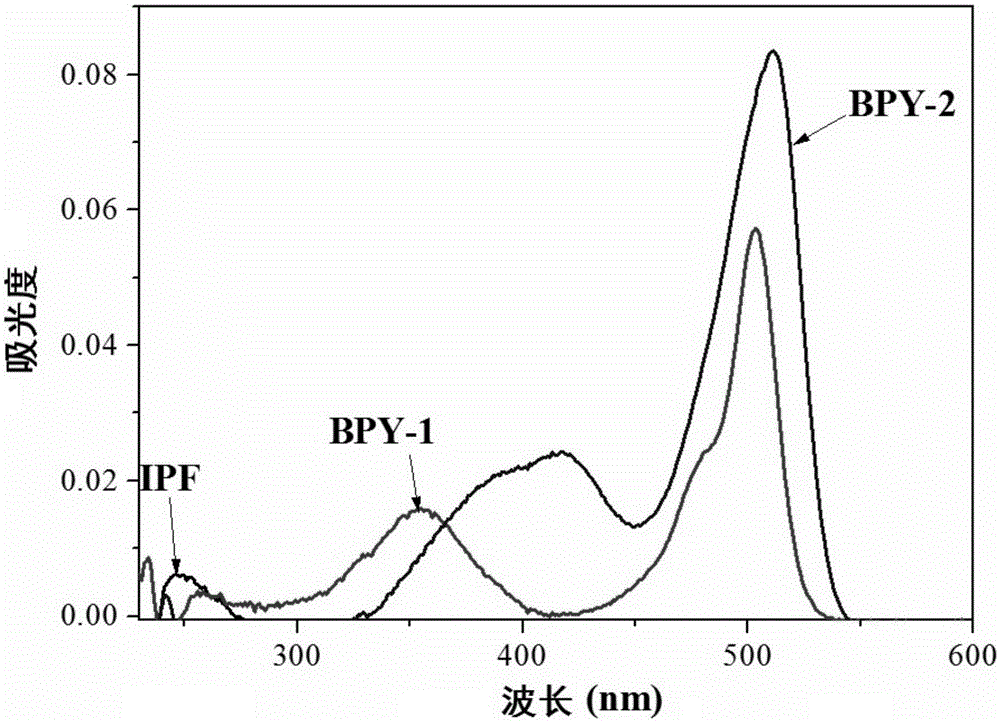

[0074] The preparation of embodiment 1 BODIPY dye-1

[0075] Preparation of BODIPY dye-1 (referred to as BPY-1) shown in formula (IV): take a 500mL single-necked bottle, dissolve 2mmol pyrrole and 1mmol p-bromobenzaldehyde in 200mL methylene chloride, and replace the Air, and use the method of argon bubbling to drive out the air in the solution, then drop a drop of trifluoroacetic acid as a catalyst, keep stirring under the protection of argon, and the reaction temperature is room temperature (25°C). After 2 hours, the reaction was terminated, and the reaction solution was washed twice with 100 mL of 0.1 mol / L NaOH solution, then the organic layer was dried with anhydrous sodium sulfate, and the solvent dichloromethane was all evaporated under argon protection conditions, and then Add 20 mL of toluene to dissolve the evaporated residue, add 1 mmol of 2,3-dichloro-5,6-dicyanobenzoquinone as an oxidant to the reaction mixture, and add 8 mmol of boron trifluoride ether solution a...

Embodiment 2

[0081] The preparation of embodiment 2 BODIPY dye-2

[0082] Prepare BODIPY dye-2 (referred to as BPY-2) shown in formula (Ⅴ): take a 500mL single-necked bottle, dissolve 2mmol pyrrole and 1mmol p-hexyloxybenzaldehyde in 200mL methylene chloride, and replace the flask with argon The air in the solution was driven out by argon bubbling, then a drop of trifluoroacetic acid was added as a catalyst, and the reaction temperature was room temperature (25° C.) while stirring continuously under the protection of argon. After 2 hours, the reaction was terminated, and the reaction solution was washed twice with 100 mL of 0.1 mol / L NaOH solution, then the organic layer was dried with anhydrous sodium sulfate, and the solvent dichloromethane was all evaporated under argon protection conditions, and then Add 20 mL of toluene to dissolve the evaporated residue, add 1 mmol of 2,3-dichloro-5,6-dicyanobenzoquinone as an oxidant to the reaction mixture, and add 8 mmol of boron trifluoride ether...

Embodiment 3

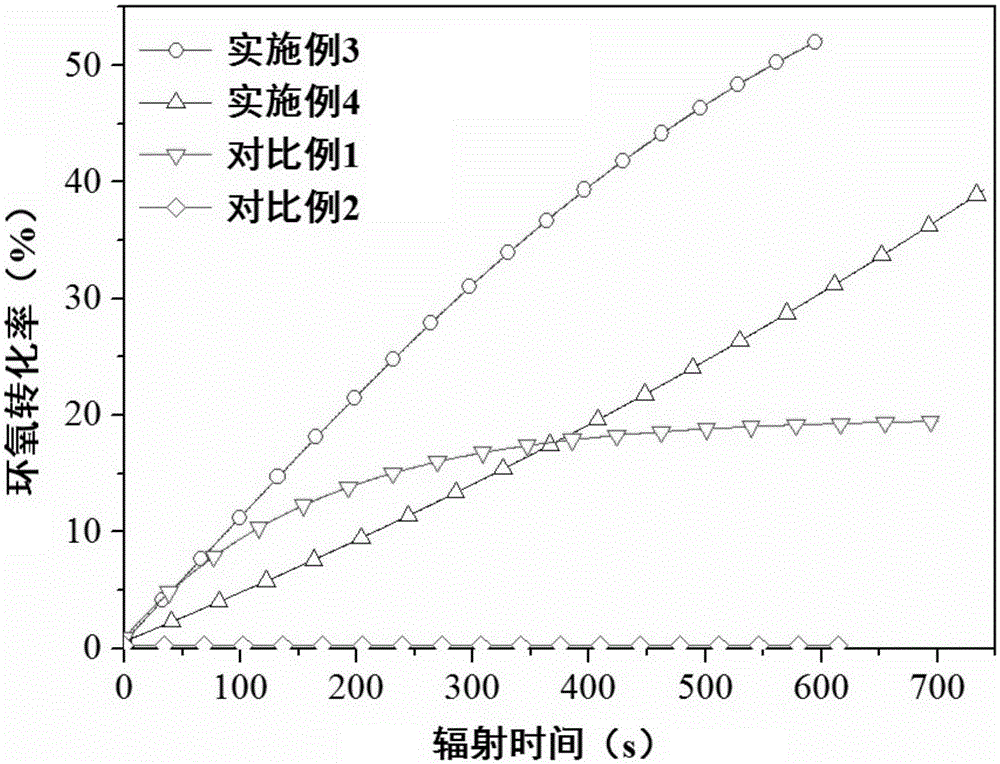

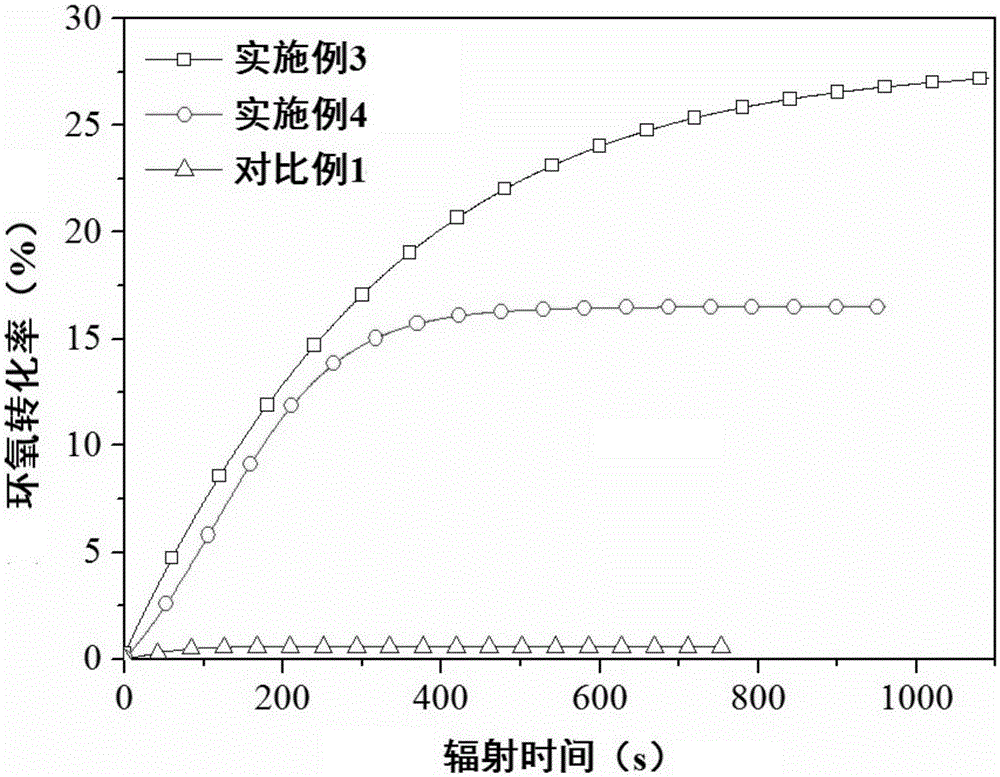

[0088] Example 3 Preparation of Cationic Visible Light Curable Composition (1)

[0089] Take by weighing 0.2000g (0.469mmol) diphenyliodonium hexafluorophosphate (IPF), add 0.1000g (0.289mmol) BODIPY dyestuff-1 (BPY-1) that embodiment 1 makes and place in brown bottle, then Add 2mL of epichlorohydrin, stir fully to completely dissolve the initiator, then add 10g of bisphenol A epoxy prepolymer E51, and stir evenly to obtain the cationic visible light curable composition, which is stored away from light.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com