Thermal insulation heat-preservation paint coating used for building external wall

A technology for heat insulation and building exterior walls, applied in the direction of reflection/signal coatings, coatings, etc., can solve problems such as not very mature, and achieve the effects of prolonging the life of coatings, good light covering effects, suppressing radiant heat and conductive heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

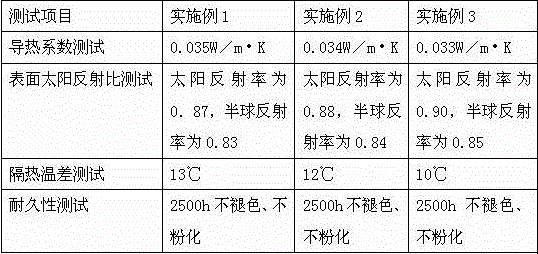

Embodiment 1

[0037] First, 40 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 1 part of N-methylol acrylamide, 6 parts of rutile titanium dioxide, 4 parts of water, 1 part of titanate coupling agent, 8 parts of additives (1 part of dithiocarbamate, 1 part of cellulose acetate butyrate, 1 part of hydroxyethyl cellulose , 1 part of pigment dispersant, 4 parts of alcohol ester twelve film-forming aids), 7 parts of mixed solvent (a mixture of ethylene glycol butyl ether and water, the ratio of parts by weight is 2:10), 9 parts of thermal insulation materials ( A mixture of hollow glass microspheres, expanded perlite and aluminum silicate fibers, the ratio of the three parts by weight is 1:1:1, among which, the hollow glass microspheres adopt the architectural coating adaptation model of Sinosteel Maanshan Mining Research Institute Co., Ltd. T32), material preparation will be carried out;

[0038] A...

Embodiment 2

[0043] First, 45 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 1.5 parts of N-methylol acrylamide, 7 parts of rutile titanium dioxide, 5 parts of water, 1.5 parts of titanate coupling agent, 12 parts of additives (1.5 parts of pentachlorophenol, 2 parts of cellulose acetate butyrate, 2 parts of hydroxyethyl cellulose, 1.5 parts of pigment Dispersant, 5 parts of alcohol ester twelve film-forming aids), 8 parts of mixed solvent (a mixture of ethylene glycol butyl ether and water, the ratio of parts by weight is 2:10), 10 parts of thermal insulation material (hollow glass microspheres , a mixture of expanded perlite and aluminum silicate fibers, the ratio of the three parts by weight is 1:1:1, among which, the hollow glass microspheres adopt the building coating adaptation model T40 of Sinosteel Maanshan Mining Research Institute Co., Ltd.), and the Prepare materials;

[0044] A kin...

Embodiment 3

[0049]First, 50 parts of emulsion (a mixture of A-102 silicone acrylic emulsion and A-99 pure acrylic emulsion, the ratio of the two parts by weight is 1.5:1), 2 parts of N-methylol acrylamide, 9 parts of rutile titanium dioxide, 6 parts of water, 2 parts of titanate coupling agent, 16 parts of additives (2 parts of dithiocarbamate, 3 parts of cellulose acetate butyrate, 3 parts of hydroxyethyl cellulose , 2 parts of pigment dispersant, 6 parts of alcohol ester twelve film-forming aids), 9 parts of mixed solvent (a mixture of ethylene glycol butyl ether and water, the ratio of parts by weight is 2:10), 12 parts of thermal insulation material ( A mixture of hollow glass microspheres, expanded perlite and aluminum silicate fibers, the ratio of the three parts by weight is 1:1:1, among which, the hollow glass microspheres adopt the architectural coating adaptation model of Sinosteel Maanshan Mining Research Institute Co., Ltd. T46), material preparation will be carried out;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com