Nickel selenide/carbon nanotube composite nanometer material and preparation and application thereof

A carbon nanotube composite and nanomaterial technology, which is applied to nickel selenide/carbon nanotube composite nanomaterials and the fields of preparation and application thereof, can solve the problems of poor conductivity of selenide, difficulty in storing batteries, and the like, and achieve capacity reduction. Attenuation, increasing particle and electron conductivity, mitigating effect of volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

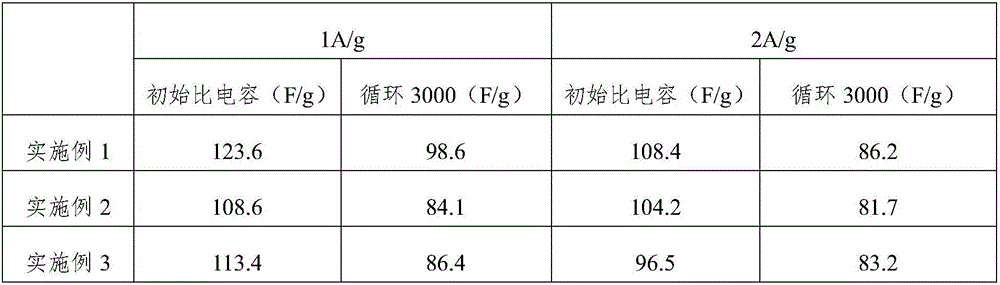

Examples

Embodiment 1

[0019] A nickel selenide / carbon nanotube composite nanomaterial is a nanowire with a length of 30 nanometers, wherein nano-spherical nickel selenide with an average particle diameter of 10 nm is attached to the carbon nanotube.

[0020] The preparation method of the nickel selenide / carbon nanotube composite nanomaterial comprises the following steps:

[0021] (1) Add 1 g of carbon nanotubes into a mixed solution of 300 mL of concentrated nitric acid and concentrated sulfuric acid, heat and reflux at 120 ° C for 8 hours, then filter with microporous filter paper, and repeatedly wash until the pH is 7, and obtain activated carbon with a concentration of 5.8 mg / mL nanotube suspension;

[0022] (2) Dissolve 0.2mol sodium selenite and 0.1mol nickel chloride in 50mL water, stir well, add activated carbon nanotube suspension to the mixed solution, ultrasonically disperse for 10-20min, and then transfer to 60mL polytetrafluoroethylene In a lined stainless steel reactor, after reactin...

Embodiment 2

[0025] A nickel selenide / carbon nanotube composite nanomaterial is a nanowire with a length of 10 nanometers, wherein nano-spherical nickel selenide with an average particle diameter of 5 nm is attached to the carbon nanotube.

[0026] The preparation method of the nickel selenide / carbon nanotube composite nanomaterial comprises the following steps:

[0027] (1) Add 1 g of carbon nanotubes into a mixed solution of 300 mL of concentrated nitric acid and concentrated sulfuric acid, heat and reflux at 120°C for 12 hours, then filter with microporous filter paper, and wash repeatedly until the pH is 7 to obtain activated carbon with a concentration of 0.1 mg / mL nanotube suspension;

[0028] (2) Dissolve 0.15mol sodium selenosulfate and 0.05mol nickel perchlorate in 50mL water, stir evenly, add activated carbon nanotube suspension into the mixed solution, ultrasonically disperse for 10-20min, and then transfer to 60mL polytetrafluoroethylene In a fluorine-lined stainless steel rea...

Embodiment 3

[0031] A nickel selenide / carbon nanotube composite nanomaterial is a nanowire with a length of 50 nanometers, wherein nano-spherical nickel selenide with an average particle diameter of 20nm is attached to the carbon nanotube.

[0032] The preparation method of the nickel selenide / carbon nanotube composite nanomaterial comprises the following steps:

[0033] (1) Add 1 g of carbon nanotubes into a mixed solution of 300 mL of concentrated nitric acid and concentrated sulfuric acid, heat and reflux at 140°C for 6 hours, then filter with microporous filter paper, and wash repeatedly until the pH is 7 to obtain activated carbon nanotubes with a concentration of 20 mg / mL. tube suspension;

[0034] (2) Dissolve 0.2mol selenium dioxide and 0.1mol nickel nitrate in 50mL water, stir well, add activated carbon nanotube suspension to the mixed solution, ultrasonically disperse for 10-20min, then transfer to 60mL polytetrafluoroethylene lining In a stainless steel reaction kettle, after r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com