Reprocessing method for improving quality of semi-finished tea or finished tea

A finished tea and reprocessing technology, applied in the direction of pre-extraction tea treatment, etc., can solve the problems of poor quality improvement effect of raw tea or finished tea, low aroma, thin taste, etc., to improve the overall sensory quality, increase sweetness, improve The effect of extraction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

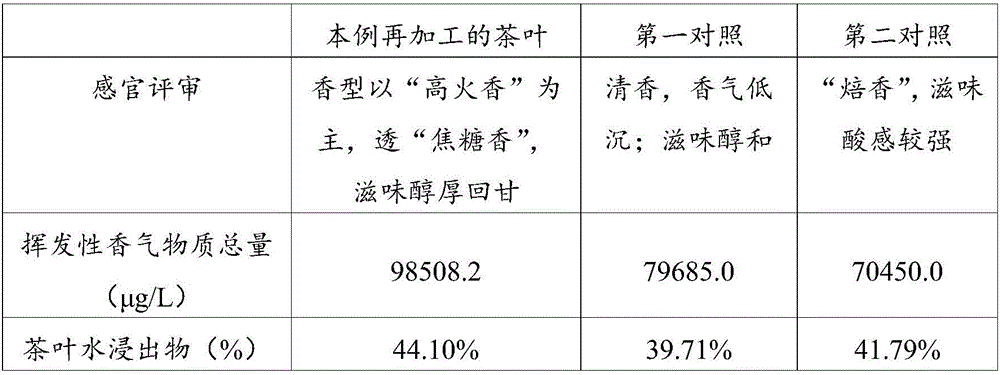

Embodiment 1

[0041] The reprocessing method for improving the quality of tea leaves in this example is as follows:

[0042] Take 100g of medium and low-grade stir-fried green tea, put it in a steamer and fumigate with boiling water for 5 minutes, when the tea leaves are fumigated and soften until the water content is 15%, take out the tea leaves, stir them up and down and let them cool to room temperature; weigh 0.3g of plant compound hydrolase and Mix 0.2g of tannin enzyme as the compound enzyme preparation of this example, dissolve the compound enzyme preparation in 120g pure water to obtain the compound enzyme solution of this example, spray the compound enzyme solution evenly in the tea leaves, and stir until the tea leaves are completely Adsorption is saturated; then the wet tea leaves are placed under constant temperature and humidity conditions of 40°C, and rehydrated for 2 hours, so that the total growth rate of reducing sugar is 100%; Prepare a sodium bicarbonate solution in an ap...

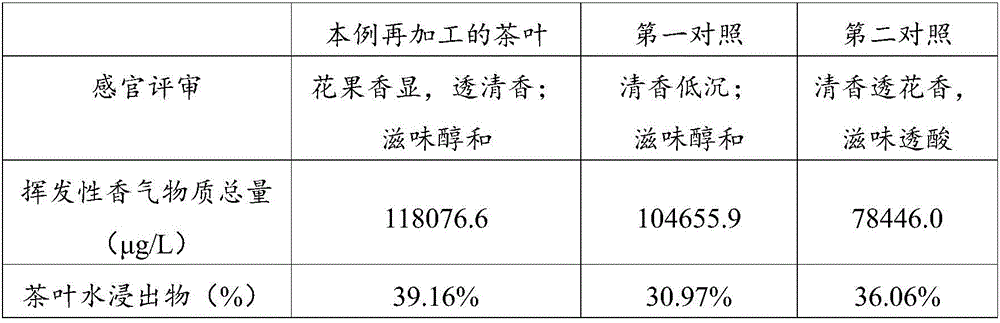

Embodiment 2

[0053] The reprocessing method for improving the quality of tea leaves in this example is as follows:

[0054] Take 100g of medium and low-grade oolong tea powder of 8 to 10 meshes, place it on a steamer and fumigate with hot water at 90°C for 10 minutes, and when the tea leaves are fumigated and softened to a moisture content of 25%, take out the tea leaves, stir them up and down and spread them to room temperature; weigh 0.6 g cellulase and 0.3g tannin are mixed as the compound enzyme preparation of this example, and the compound enzyme preparation is dissolved in 400g pure water to obtain the compound enzyme solution of this example, and the compound enzyme solution is evenly sprayed in the tea leaves, and stir until the tea leaves are completely adsorbed and saturated; then place the wet tea leaves under constant temperature and humidity conditions at 50°C, rehydrate and enzymatically hydrolyze for 2.5 hours, so that the total reducing sugar growth rate is 60%; after the en...

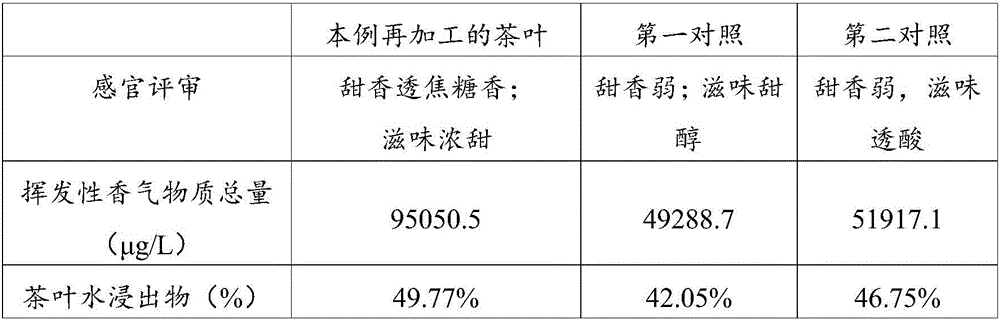

Embodiment 3

[0062] The reprocessing method for improving the quality of tea leaves in this example is as follows:

[0063]Take 100g of medium and low-grade black tea, put it on a steamer and fumigate with hot water at 90°C for 10 minutes, and when the tea leaves are fumigated and softened to a water content of 25%, take out the tea leaves, stir them up and down and let them cool to room temperature; weigh 0.3g of β-glucosidase , 0.2g laccase and 0.2g tannin are mixed as the compound enzyme preparation of this example, and the compound enzyme preparation is dissolved in 300g pure water to obtain the compound enzyme solution of this example, and the compound enzyme solution is evenly sprayed in the tea leaves , and stirred until the tea leaves were completely adsorbed and saturated; then the wet tea leaves were placed under constant temperature and humidity conditions of 45°C, rehydrated and enzymatically hydrolyzed for 1.5 hours, and the growth rate of the total reducing sugar was 70%; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com