Pre-preparation method of shrimp food dish

A food and dish technology, applied in the field of shrimp food production, can solve the problems that dishes are not suitable for overnight transformation, lack of quality standard system, and difficulty in industrial transformation, so as to achieve easy industrial transformation, avoid mutual interference, and improve storage quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

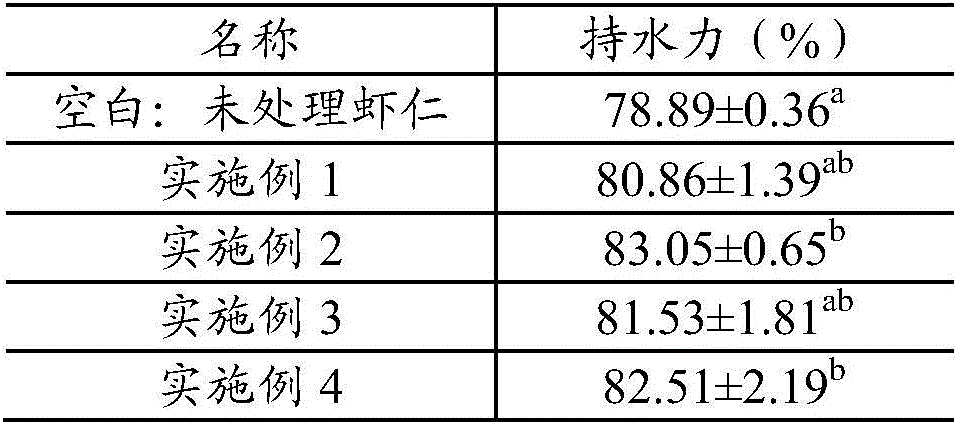

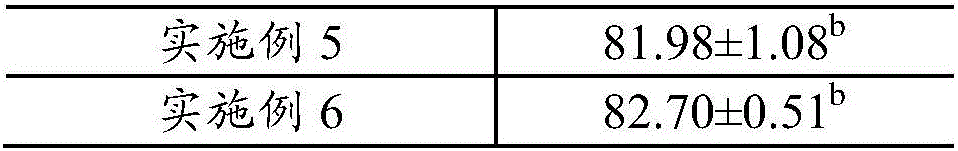

Examples

Embodiment 1

[0041]Fresh shrimp raw materials are cleaned, shelled and meat removed, and shrimp lines are removed. Add 5 times its mass of water to the dried shiitake mushrooms, rehydrate for 1 hour, wash, remove and drain. Add 6 times its mass of water to the rehydrated shiitake mushrooms, cook at 80°C for 4 hours, filter through an 80-mesh sieve, and cool to room temperature for later use. Put the pretreated shrimp into the dried shiitake mushroom preparation solution of 1.5 times its mass, soak at 4°C for 2 hours, stir every 15 minutes during the soaking period, remove and drain. The ratio of pretreated shrimp, vegetables, nuts, dried shiitake mushroom pre-prepared liquid and seasoning, in terms of parts by mass, is as follows: 400 parts of pretreated shrimp; 25 parts of peas, 25 parts of diced carrots, 40 parts of sweet corn kernels, and pine nuts. 10 parts, washed, blanched in boiling water for 8 minutes, cooled to room temperature for later use; 80 parts of dried shiitake mushroom p...

Embodiment 2

[0043] Frozen shrimp were thawed at 4°C for 6 hours, washed, shelled and meat removed, and shrimp lines were removed. Chop fresh oyster mushrooms, add 5 times its mass of water, cook at 80°C for 2 hours, filter through an 80-mesh sieve, and cool to room temperature for later use. Put the pretreated shrimp into the fresh oyster mushroom pre-preparation solution with twice its mass, soak it at 10°C for 3 hours, stir it every 20 minutes during the soaking period, remove it and drain it. Pre-treated shrimp, vegetables, nuts, fresh oyster mushroom pre-prepared liquid and seasoning, in terms of parts by mass, the proportions are: 450 parts of pre-treated shrimp; 22 parts of peas, 22 parts of diced carrots, 50 parts of sweet corn kernels, and pine nuts. 10 parts, washed, blanched in boiling water for 10 minutes, cooled to room temperature for later use; 65 parts of fresh oyster mushroom preparation solution, 3.5 parts of salt, 2 parts of sesame oil. Preparation of fish gelatin ice c...

Embodiment 3

[0045] Thaw the frozen shrimp at 10°C for 5 hours, wash, remove and drain, and remove the shrimp line. Add 10 times its mass of water to the dried fungus, rehydrate for 2 hours, wash, remove and drain. The rehydrated fungus was added with 7 times its mass of water, boiled at 80° C. for 4 hours, filtered through an 80-mesh sieve, and cooled to room temperature for use. Put the pretreated shrimp into the dry fungus pre-preparation solution with 1.5 times its mass, soak it at 4°C for 2.5 hours, stir it every 15 minutes during the soaking period, remove it and drain it. Pre-treated shrimp, vegetables, nuts, dried fungus pre-prepared liquid and seasoning, in terms of parts by mass, the proportions are: 400 parts of pre-treated shrimp; 25 parts of peas, 25 parts of diced carrots, 35 parts of sweet corn kernels, and pine nuts 10 parts, washed, blanched in boiling water for 10 minutes, removed and drained, cooled to room temperature for use; 80 parts of dried fungus pre-preparation s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com