Extraction method and applications of oat avenanthramides

An oat alkaloid and extraction method technology, which is applied in the field of daily-use chemicals, can solve the problems of long extraction time, low extraction efficiency, solvent residue, etc., and achieve the effects of easy industrial production, simple and easy method, and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

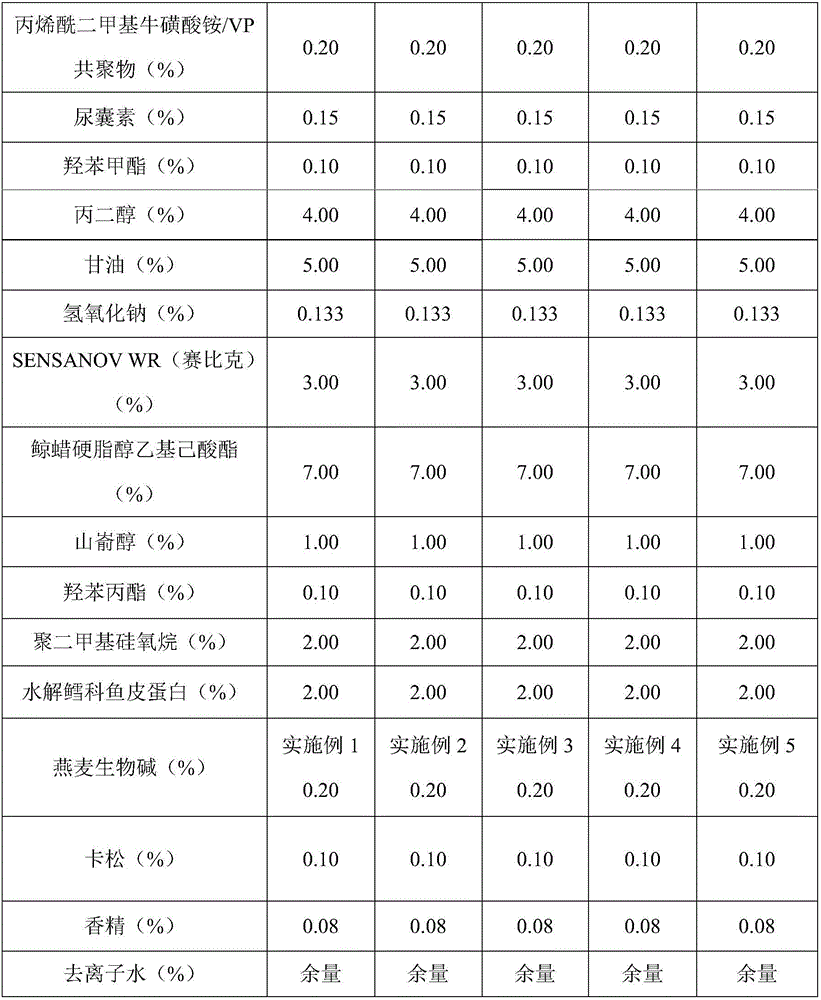

Embodiment 1

[0030] Grind naked oats, pass through a 40-mesh sieve, take 5kg of pulverized oats, then add 90% ethanol solution 20 times the weight of oats to obtain a mixed solution, add 25g of cellulase, adjust the pH value to 5.5, and place in a water bath at 30°C with Stir at 50 rpm for 1 hour. Put the enzymolysis solution into the centrifuge, centrifuge at 1000rpm, remove the liquid, and keep the solid. The treated oats enter the subcritical extraction device for subcritical extraction. The extraction temperature is 50°C, the pressure is 3MPa, and propane is used for extraction. agent, propane contains 2% entraining agent, entraining agent is ethanol, reclaims extractant, discharges, and obtains oat alkaloid extract, detects by HPLC method, and the extraction rate of oat extract is 9.2%, and oat alkaloid content is 4.62%.

Embodiment 2

[0032] Grind naked oats, pass through a 40-mesh sieve, take 7.5kg of crushed oats, then add 90% ethanol solution 30 times the weight of oats to obtain a mixed solution, add 52g of pectinase, adjust the pH to 6.0, and place in a water bath at 40°C at 100rpm Stir at high speed for 1 hour. Put the enzymolysis solution into the centrifuge, centrifuge at 1000rpm, remove the liquid, and keep the solid. The treated oats enter the subcritical extraction device for subcritical extraction. The extraction temperature is 55°C, the pressure is 3MPa, and propane is used for extraction. agent, butane contains 2.5% entraining agent, the entraining agent is butanol, the extractant is recovered, and the material is discharged to obtain the oat alkaloid extract, which is detected by HPLC method, and the extraction rate of the oat extract is 9.8%, and the oat alkaloid The content is 4.38%.

Embodiment 3

[0034] Naked oats are pulverized, cross 60 mesh sieves, get the oats that 9kg pulverizes, then add oats, 80% ethanol solution of 20 times of weight, obtain mixed liquor, add 72g compound enzyme (cellulase and pectinase are 1 by mass ratio :1), adjust the pH to 5.0 and stir for 1 hour at a speed of 50 rpm in a 40° C. water bath. Put the enzymolysis solution into the centrifuge, centrifuge at 1000rpm, remove the liquid, and keep the solid. The treated oats enter the subcritical extraction device for subcritical extraction. The extraction temperature is 70°C, the pressure is 3MPa, dimethyl ether As an extractant, dimethyl ether contains 2% entrainer, and the entrainer is ethanol and butanol, and the components are 80% ethanol and 20% butanol by weight; the extractant is recovered, and the material is discharged to obtain the oat alkaloid extraction Detected by HPLC method, the extraction rate of oat extract is 10.5%, and the alkaloid content of oat is 4.72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com