VOCs (volatile organic chemicals) removing technology of automobile painting industry

A coating and industry-leading technology, applied in the field of removal of low-concentration VOCs in the automotive coating industry, can solve problems affecting practical application, VOCs entry, high investment costs, etc., and achieve the effects of short action time, low price, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

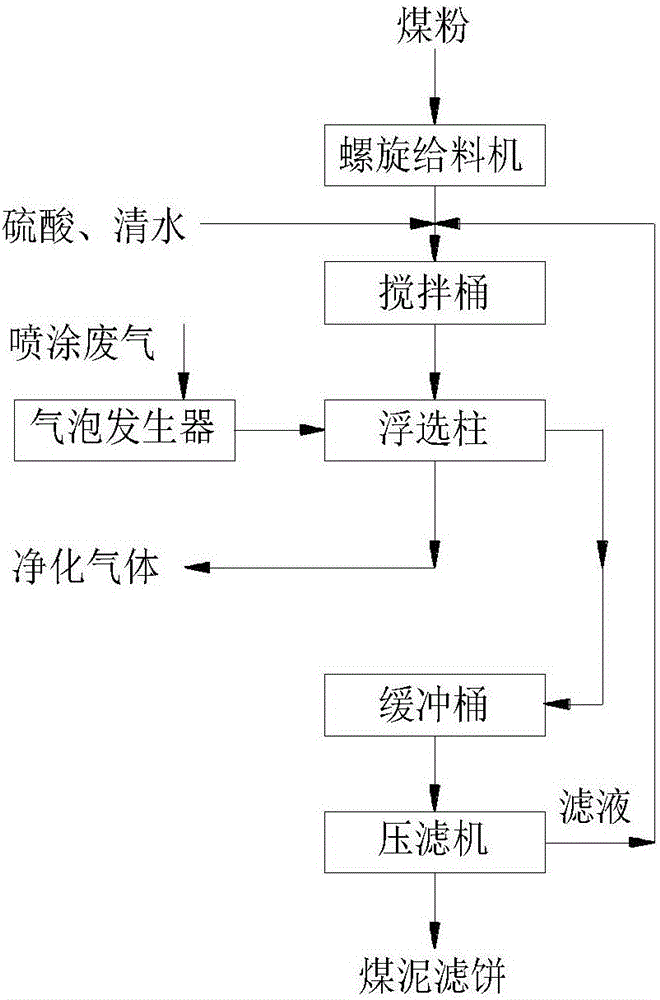

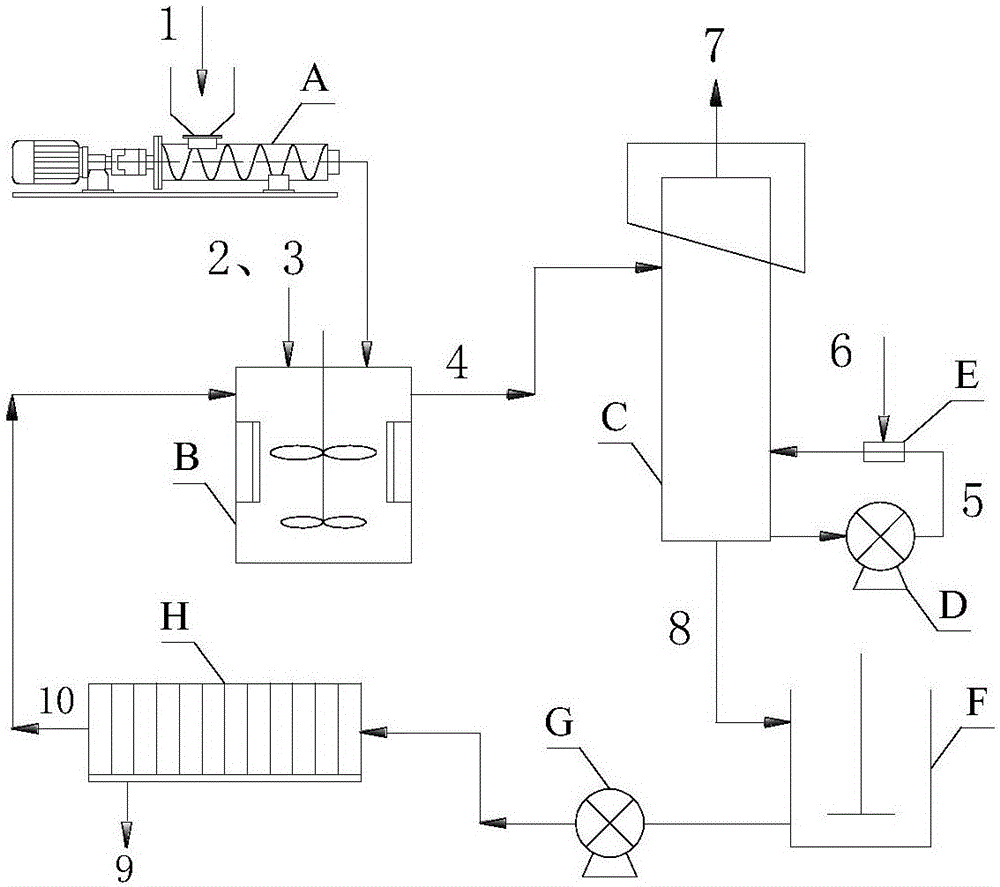

[0028] Such as figure 2 As shown, the equipment used includes screw feeder A, slurry mixing tank B, flotation column C, circulation pump D, bubble generator E, buffer tank F, filter press feed pump G, filter press H; Proceed as follows:

[0029] a. The long-flame coal fine-grained coal powder 1 with a particle size of -0.074mm and a particle size of 70-80% is evenly fed into the mixing tank B through the screw feeder A, and the filtrate 10 filtered by the filter press is returned to the In the mixing tank B, add sulfuric acid 2 and clear water 3 at the same time to ensure that the mixed fine coal slurry in the mixing tank has a pH of 5.0 and a concentration of 200g / L; after mixing and stirring for 5 minutes, the fine coal slurry 4 is fed into the flotation column within C;

[0030] b. Set the VOCs concentration to 100.5mg / m 3 The paint spraying exhaust gas 6 is sucked into the bubble generator E and the pipeline by the circulating pump D under the negative pressure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com