Preparation method of magnetic biochar adsorbing material for arsenic-cadmium combined pollution remediation

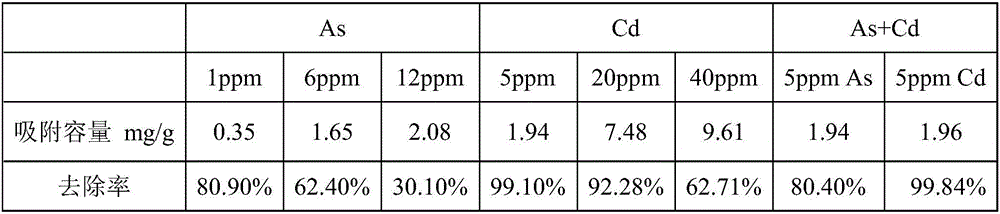

A technology of composite pollution and adsorption materials, which is applied in the field of preparation of magnetic biochar adsorption materials, can solve problems such as difficult separation and poor arsenic adsorption capacity, and achieve the effect of simple preparation process, low cost, and realization of arsenic and cadmium composite pollution repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

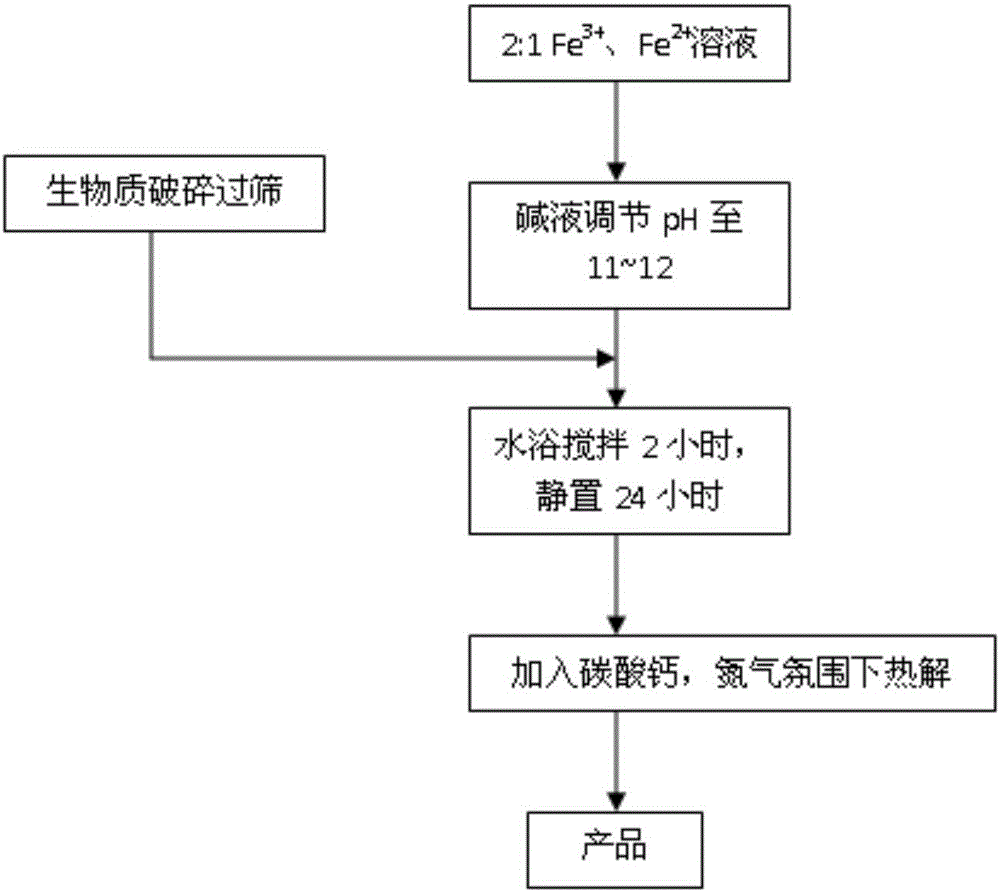

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, a kind of preparation method of magnetic biochar adsorption material, carries out following steps successively:

[0045] 1), drying the rice straw to a moisture content of ≤10%, and then pulverizing it until it can pass through a 20-mesh sieve, as biomass;

[0046]2), weigh 11.12g (0.04mol) FeSO 4 ·7H 2 O and 21.64g (0.08mol) FeCl 3 ·6H 2 O was placed in a 1L three-necked flask and dissolved in 400mL deionized water to prepare a mixed solution of 0.1mol / L ferrous iron and 0.2mol / L ferric iron-iron salt solution, and add 5mol / L NaOH under stirring Adjust the pH of the iron salt solution to 11-12; add 20 g of the biomass obtained in step 1), heat and stir in a water bath at 60° C. for 2 hours, and finally cover the beaker with plastic wrap and let stand for 24 hours.

[0047] 3) The product obtained in step 2) is subjected to suction filtration, and vacuum-dried at 500-1500 Pa and 50°C for 24 hours; a dried solid is obtained.

[0048] Add calcium carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com