Method for directly synthesizing Al-MCM-41 mesoporous molecular sieve from kaolin or Hangjin 2# soil

A technology of mesoporous molecular sieve and kaolin, applied in the direction of crystalline aluminosilicate zeolite, nanotechnology, etc., to achieve the effect of reducing process energy consumption, saving synthesis cost and shortening synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

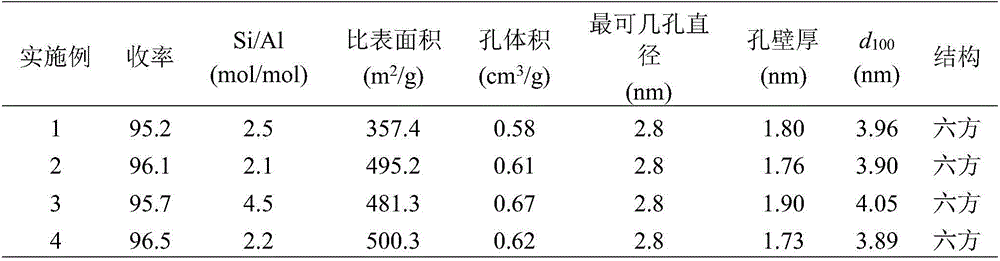

Examples

Embodiment 1

[0016] Synthesis of Al-MCM-41 mesoporous molecular sieve from coal-series kaolin 1: Mix coal-series kaolin 1 and 4mol / L sulfuric acid at a ratio of 1g:10mL, boil and reflux for 2 hours, cool naturally, wash with water once to neutral, suction filter, 60 ℃ drying for 6 hours to obtain acidified kaolin 1. Take 100 mL of 0.2 mol / L sodium hydroxide aqueous solution and keep the temperature in a water bath at 70°C; add 1.5 g of CTABr and stir to dissolve it; then add 4 g of acidified kaolin 1 and continue stirring for 1 hour; add 1 mol / L sulfuric acid dropwise to adjust the pH of the solution =10, continue stirring for 1 hour. The obtained mixture was transferred into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and was allowed to stand at 110° C. for 12 hours for crystallization. After natural cooling, the obtained product was suction-filtered and washed with water once until neutral; the solid product was dried at 60°C for 6 hours, and then calcined in an air at...

Embodiment 2

[0018] Synthesis of Al-MCM-41 mesoporous molecular sieve from coal-series kaolin 2: Mix coal-series kaolin 2 and 4mol / L sulfuric acid at a ratio of 1g:10mL, boil and reflux for 2 hours, cool naturally, wash with water once to neutral, suction filter, 60 ℃ drying for 6 hours to obtain acidified kaolin 2. Take 100 mL of 0.2 mol / L sodium hydroxide aqueous solution and keep the temperature in a water bath at 70°C; add 1.5 g of CTABr and stir to dissolve it; then add 4 g of acidified kaolin 2 and continue stirring for 1 hour; add 1 mol / L sulfuric acid dropwise to adjust the pH of the solution =10, continue stirring for 1 hour. The obtained mixture was transferred into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and was allowed to stand at 110° C. for 12 hours for crystallization. After natural cooling, the obtained product was suction-filtered and washed with water once until neutral; the solid product was dried at 60°C for 6 hours, and then calcined in an air at...

Embodiment 3

[0020] by Hang Jin 2 # Synthesis of Al-MCM-41 Mesoporous Molecular Sieves from Earth: Hang Jin 2 # Soil and 4mol / L sulfuric acid were mixed at a ratio of 1g:10mL, boiled and refluxed for 2 hours, cooled naturally, washed with water once until neutral, filtered with suction, dried at 60°C for 6 hours to obtain acidified Hangjin 2 # Soil (activated clay). Take 100 mL of 0.2 mol / L sodium hydroxide aqueous solution and keep the temperature in a water bath at 70°C; add 1.5 g of CTABr and stir to dissolve it; then add 4 g of activated clay and continue stirring for 1 hour; add 1 mol / L sulfuric acid dropwise to adjust the pH of the solution. 10. Continue stirring for 1 hour. The obtained mixture was transferred into a polytetrafluoroethylene-lined hydrothermal reaction kettle, and was allowed to stand at 110° C. for 12 hours for crystallization. After natural cooling, the obtained product was suction-filtered and washed with water once until neutral; the solid product was dried at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com