A kind of conical titanium dioxide nanorod and preparation method thereof

A technology of titanium dioxide and nanorods, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve problems such as inability to guarantee photocatalytic efficiency, and achieve the effect of uniform size and uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] For overcoming the deficiencies in the prior art, the invention provides a kind of preparation method of conical titania nanorod, comprising the following steps:

[0043] (1) Add CTAB and DDAB respectively to the water, then add ammonia water with a volume fraction of 1.7% to the solution, stir at a constant temperature and at a constant speed to prepare a mixed solution a;

[0044] Wherein, the temperature during the stirring process is 32-37°C; preferably: the stirring temperature is 35°C.

[0045] Stir for 2-3h after adding ammonia water, preferably: stir for 2h.

[0046] (2) TTIP is added to the mixed solution a prepared by the above step (1), stirred at a constant temperature and at a constant speed to obtain a suspension b;

[0047] Wherein, after adding TTIP, stir and mix for 12-36 hours, preferably: stir and mix for 24 hours.

[0048] (3) Transfer the suspension b prepared by step (2) to a reactor, place it in a constant temperature box, and carry out a hydrot...

Embodiment 1

[0059] Add 0.15 g of CTAB and 0.15 g of DDAB to 40 mL of deionized water at a temperature of 35 ° C and stir overnight at a constant speed, then add 0.68 mL of ammonia water with a volume ratio of 1.7% to the solution, and stir for 2 hours to obtain a mixed solution; Add gTTIP to the above mixed solution, stir at a constant temperature and speed for 12 hours to obtain a milky white suspension; transfer the milky white suspension prepared above to the reactor, and place it in a thermostat at 150°C for a hydrothermal reaction for 24 hours; after the above hydrothermal reaction The milky white suspension was centrifuged, washed, dried, ground, and calcined at 450° C. for 4 hours to obtain titanium dioxide powder.

Embodiment 2

[0061] Add 0.15 g of CTAB and 0.15 g of DDAB to 40 mL of deionized water at a temperature of 35 ° C and stir overnight at a constant speed, then add 0.68 mL of ammonia water with a volume ratio of 1.7% to the solution, and stir for 2 hours to obtain a mixed solution; Add gTTIP dropwise to the above mixed solution, stir at a constant temperature for 24 hours to obtain a milky white suspension; transfer the milky white suspension prepared above to the reactor, and place it in a thermostat at 150°C for a hydrothermal reaction for 24 hours; The resulting milky white suspension was centrifuged, washed, dried, ground, and calcined at 450° C. for 4 hours to obtain titanium dioxide powder.

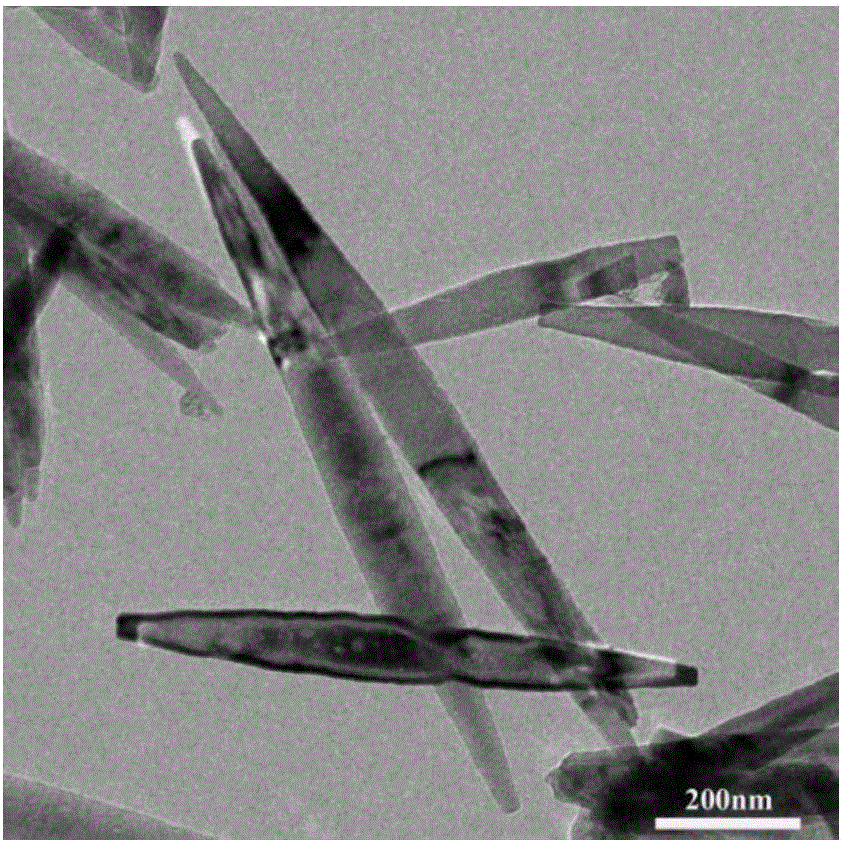

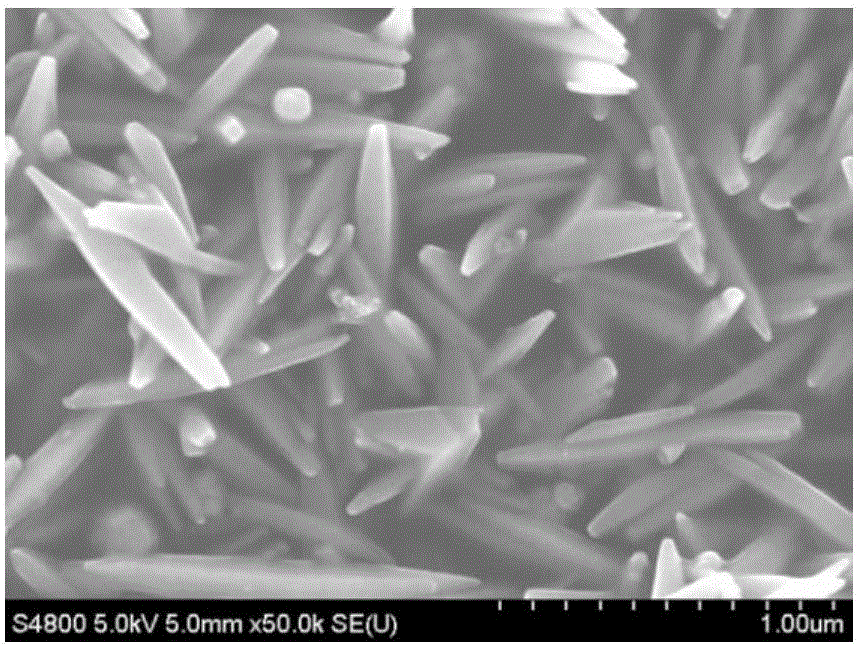

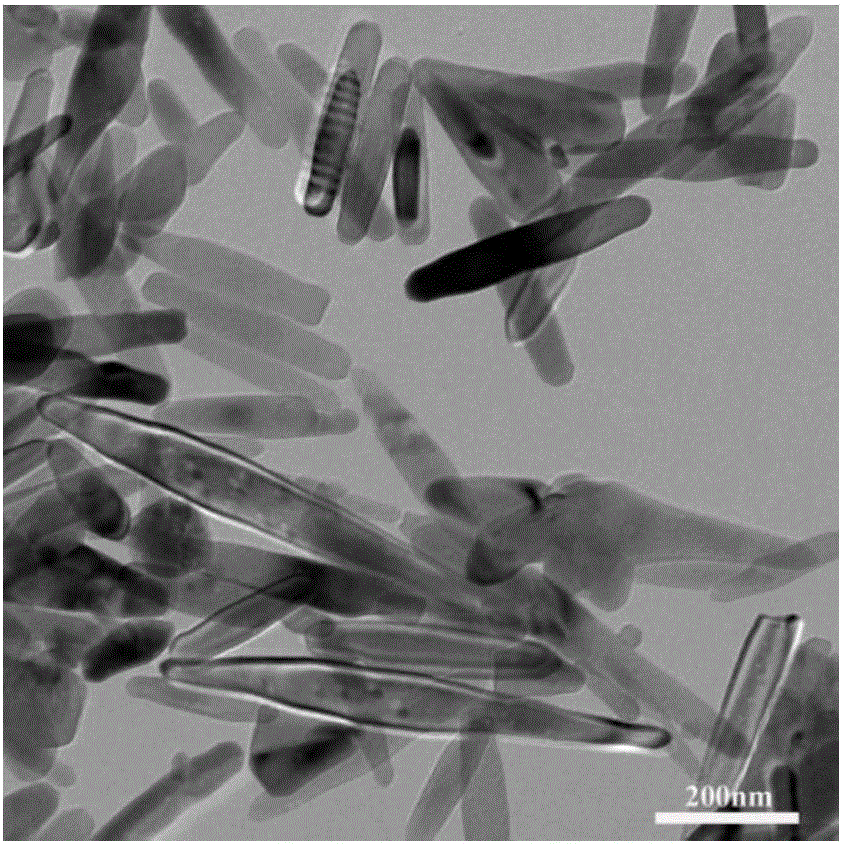

[0062] Observation with transmission electron microscope and scanning electron microscope, such as figure 1 and figure 2 As shown, the conical titanium dioxide nanorods prepared by this method have a shape of conical nanorods with two pointed ends. The maximum diameter of a single nanorod is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com