KMnF3 nanowire and preparation method thereof

A nanowire, oil-soluble technology, applied in the field of preparation of KMnF3 nanowires, can solve the problems of being unsuitable for large-scale production, difficult to elute the solvent, uneven reaction, etc., and achieve suitable for large-scale production, uniform product morphology, The effect of the simple method of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

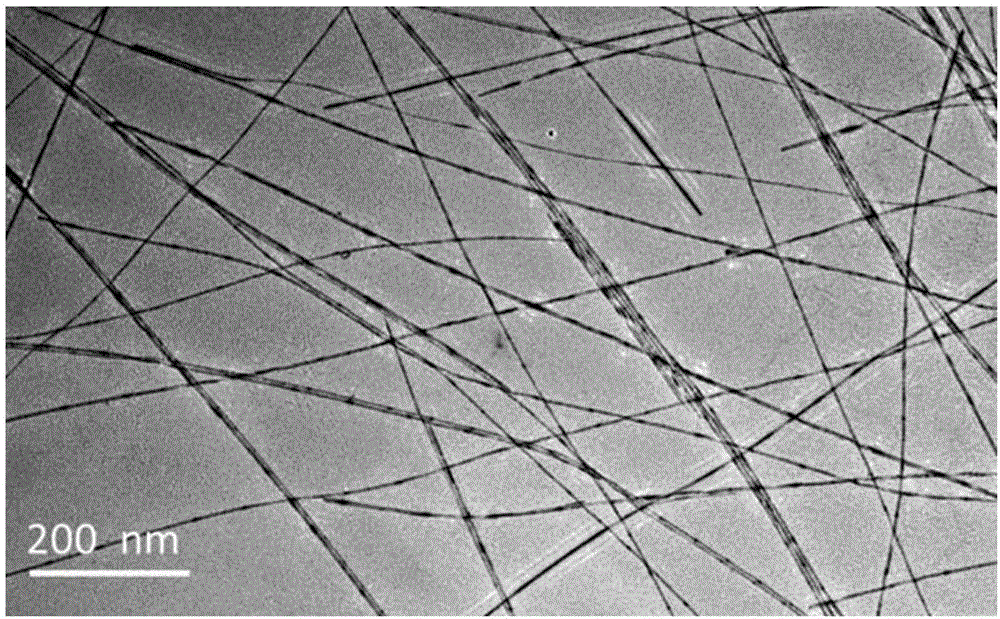

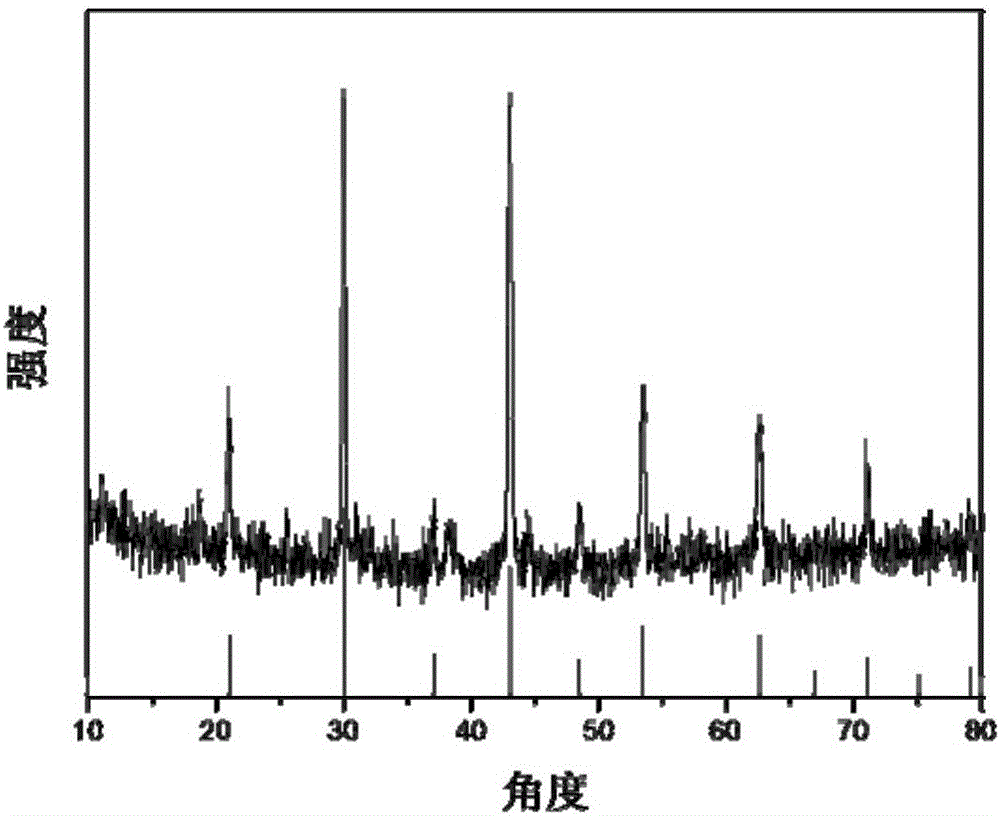

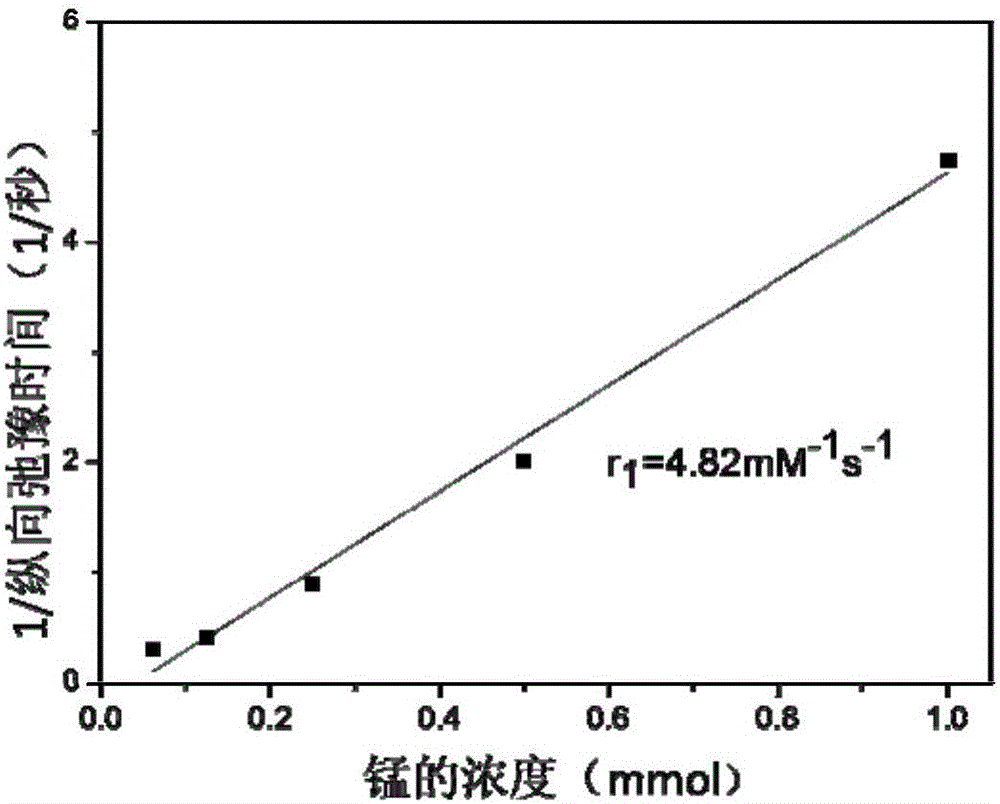

[0023] This embodiment prepares KMnF according to the following steps 3 Nanowires:

[0024] a. Add 6.00g Mn(CH 3 COOH) 2 and 28.00g of sodium oleate were dissolved in a mixture of 38mL of distilled water, 70mL of n-hexane and 28mL of ethanol, stirred evenly, then stirred and kept at 60°C for 9h. The resulting reaction solution was moved to a separatory funnel, washed with water three times, and the wine-red solution in the upper layer was the prepared manganese oleate solution, which was vacuum-dried to obtain manganese oleate;

[0025] b. Add 0.21g manganese oleate to the mixed solution of 4.5mL oleic acid, 4mL oleylamine and 13mL octadecene, stir evenly; then vacuumize at 100°C for 8min to remove water, then lower to room temperature to obtain a mixed reaction liquid;

[0026] c. Add 7mL of methanol solution with 0.25g of KF into the mixed reaction solution and stir evenly; first heat to 75°C and keep warm for 15mim to remove methanol; then raise the temperature to 105°C...

Embodiment 2

[0031] This embodiment prepares KMnF according to the following steps 3 Nanowires:

[0032] a, 5.00gMnCl 2 and 20.00g of sodium oleate were dissolved in a mixture of 34mL of distilled water, 59mL of n-hexane and 25mL of ethanol, stirred evenly, then stirred and kept at 50°C for 8h. The resulting reaction solution was transferred to a separatory funnel, washed with water three times, and the wine-red solution in the upper layer was the prepared manganese oleate solution, which was vacuum-dried to obtain manganese oleate.

[0033] b. Add 0.09g manganese oleate into the mixed solution of 2mL oleic acid, 3mL oleylamine and 9mL octadecene, and stir evenly. Vacuum at 90°C for 5 minutes to remove water, then lower to room temperature to obtain a mixed reaction solution.

[0034] c. Add 3mL of methanol solution with 0.08g of KF into the mixed reaction solution and stir evenly; first heat to 50°C and keep warm for 10mim to remove methanol; then raise the temperature to 90°C, vacuumi...

Embodiment 3

[0038] This embodiment prepares KMnF according to the following steps 3 Nanowires:

[0039] a. Add 9.00gMn(NO 3 ) 2 and 35.00g of sodium oleate were dissolved in a mixture of 45mL of distilled water, 83mL of n-hexane and 38mL of ethanol, stirred evenly, then stirred and kept at 90°C for 12h. The resulting reaction solution was transferred to a separatory funnel, washed with water three times, and the wine-red solution in the upper layer was the prepared manganese oleate solution, which was vacuum-dried to obtain manganese oleate.

[0040] b. Add 0.243g manganese oleate into the mixed solution of 5mL oleic acid, 7mL oleylamine and 15mL octadecene, and stir evenly. Vacuum at 110° C. for 10 minutes to remove water, and then lower to room temperature to obtain a mixed reaction solution.

[0041] c. Add 8mL methanol solution with 0.296g KF into the mixed reaction solution, stir evenly; first heat to 80°C, keep warm for 30mim to remove methanol; then raise the temperature to 110...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com