A method for recovering elemental phosphorus from hypophosphite wastewater

A technology of hypophosphite and recovery sheet, which is applied in the direction of phosphorus preparation, metallurgical wastewater treatment, chemical instruments and methods, etc., can solve the problems of low utilization rate, low recovery rate of hypophosphite, difficult recovery of hypophosphite, etc., to achieve The effect of high recovery rate, reduction of secondary pollution, and relief of pollution control pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] The method for recovering elemental phosphorus from hypophosphite wastewater provided by the embodiments of the present invention includes:

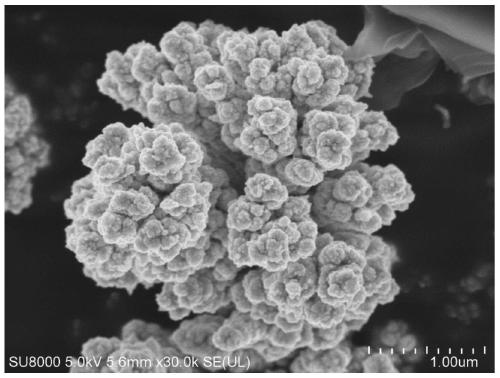

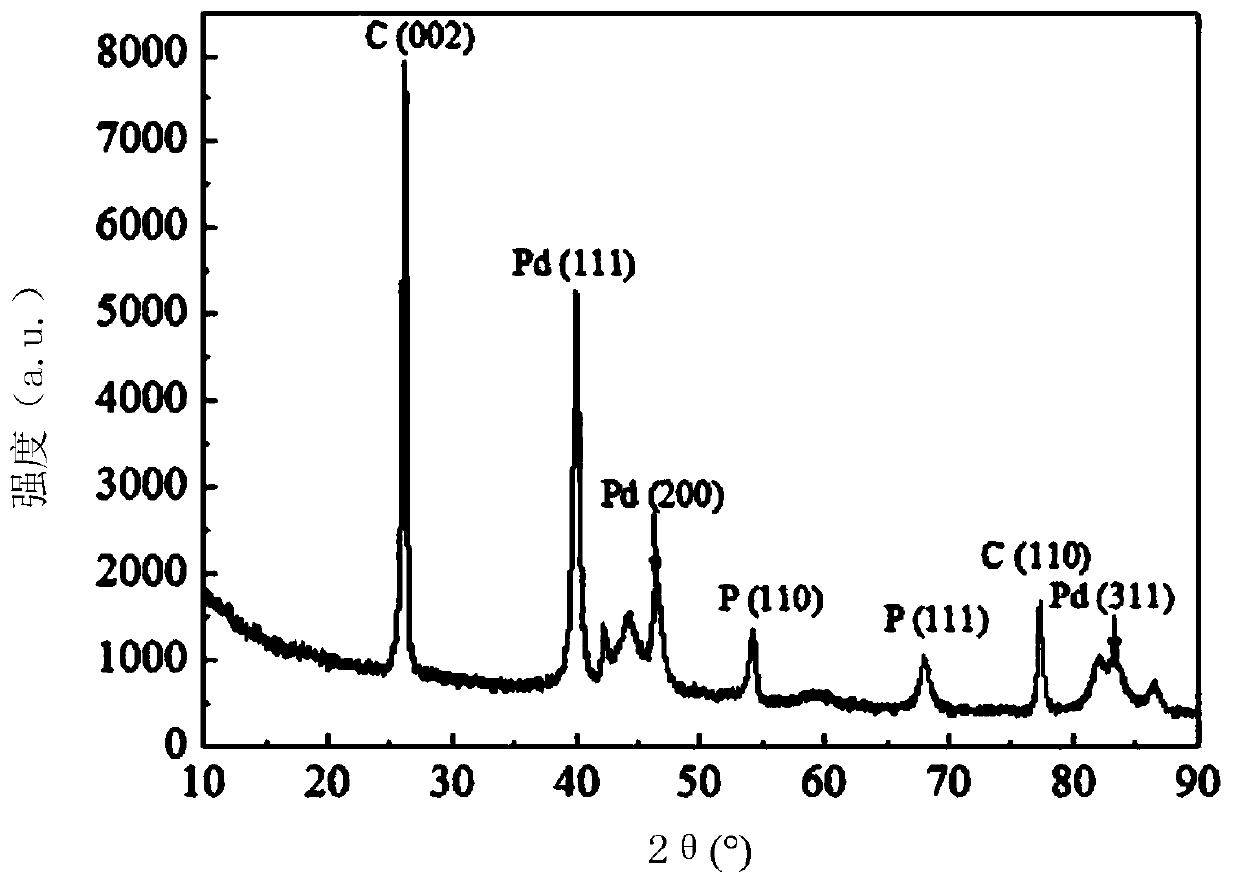

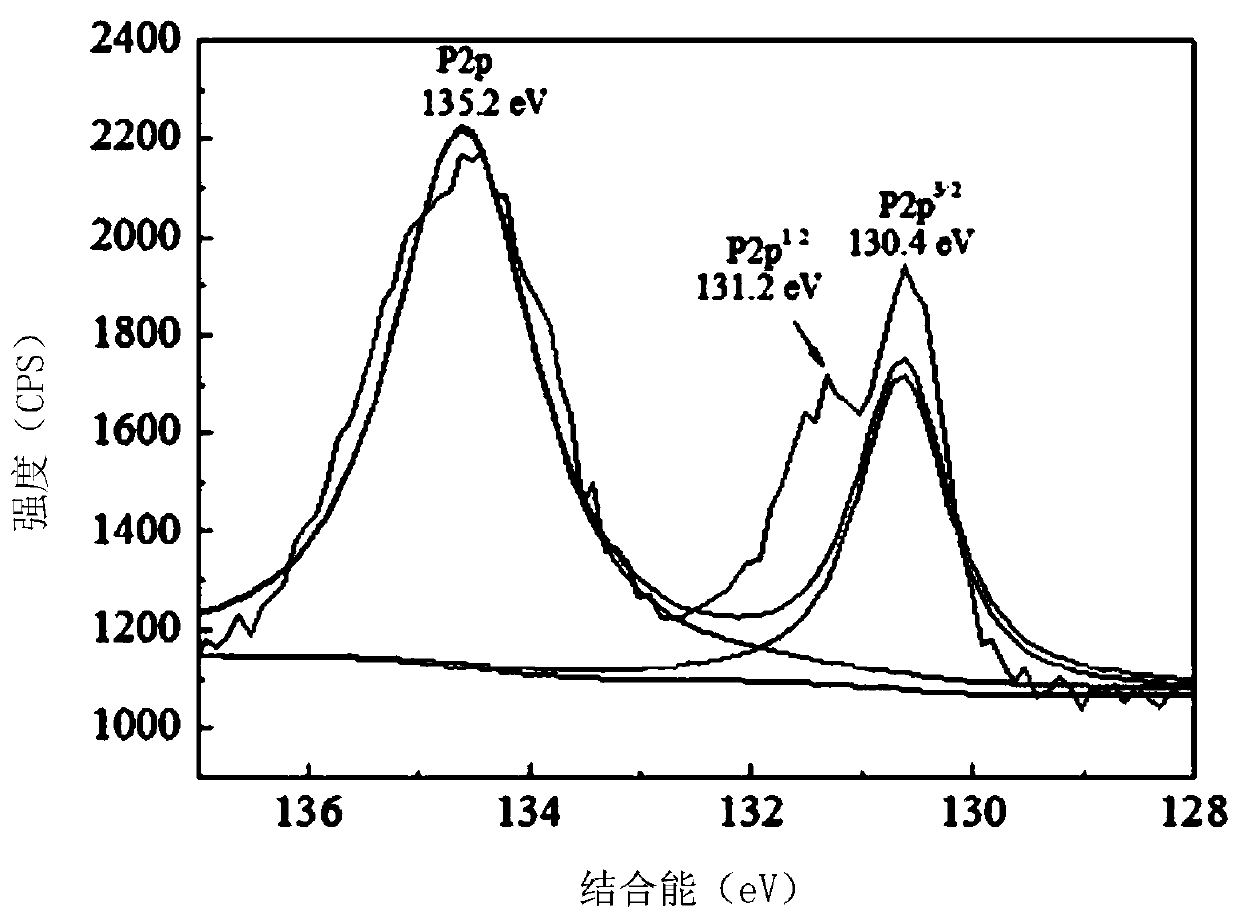

[0049] S101: Construct a photoelectrocatalytic reaction system, in which graphite is used as the anode plate 2, Pd / g-C 3 N 4 The electrode is the cathode plate 3, the xenon lamp is the light source 5, and the Nafion proton exchange membrane 6 isolates the device corresponding to the photocatalytic reaction system into an anode chamber and a cathode chamber, and the volume ratio of the anode chamber and the cathode chamber is 1:5;

[0050] S102: adjust the plate spacing between the anode plate and the cathode plate to be 2 cm, and insert the pH meter 7 into a device corresponding to the photocatalytic reaction system;

[0051] S103: Pump the ammonium citrate, sodium sulfate, and hypophosphite wastewater in the raw material pool 12 into the cathode chamber through the metering pump 10, and control the pH value of the hypophosphite ...

Embodiment 2

[0064] The method for recovering elemental phosphorus from hypophosphite wastewater provided by the embodiments of the present invention includes:

[0065] S201: Construct a photoelectrocatalytic reaction system, in which stainless steel is used as the anode plate 2, Pd / g-C 3 N 4 The electrode is the cathode plate 3, the fluorescent lamp is the light source 5, and the Nafion proton exchange membrane 6 isolates the device corresponding to the photocatalytic reaction system into an anode chamber and a cathode chamber, and the volume ratio of the anode chamber and the cathode chamber is 1:5;

[0066] S202: Adjust the plate spacing between the anode plate and the cathode plate to 1 cm, and insert the pH meter 7 into a device corresponding to the photocatalytic reaction system;

[0067] S203: Pump the ammonium citrate, sodium sulfate, and hypophosphite wastewater in the raw material pool 12 into the cathode chamber through the metering pump 10, and control the pH value of the hypo...

Embodiment 3

[0080] The method for recovering elemental phosphorus from hypophosphite wastewater provided by the embodiments of the present invention includes:

[0081] S301: Construct a photoelectric catalytic reaction system, in which graphite is used as the anode plate 2, Pd / g-C 3 N 4 The electrode is the cathode plate 3, the sunlight is the light source 5, and the Nafion proton exchange membrane 6 isolates the device corresponding to the photocatalytic reaction system into an anode chamber and a cathode chamber, and the volume ratio of the anode chamber and the cathode chamber is 1:5;

[0082] S302: adjust the plate spacing between the anode plate and the cathode plate to be 10 cm, and insert the pH meter 7 into the device corresponding to the photocatalytic reaction system;

[0083] S303: Pump the ammonium citrate, sodium sulfate, and hypophosphite wastewater in the raw material pool 12 into the cathode chamber through the metering pump 10, and control the pH value of the hypophosphi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com