Method for removing micro or trace amount of N-nitrosodimethylamine in water by self-assembled metal coordination polymer catalyst film

A technology for the reaction of nitrosodimethylamine and nitrosodimethylamine, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve N- High water solubility of nitrosodimethylamine, long reaction time of biodegradation method, low Henry's law constant, etc., to achieve remarkable removal effect, technical feasibility, good economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

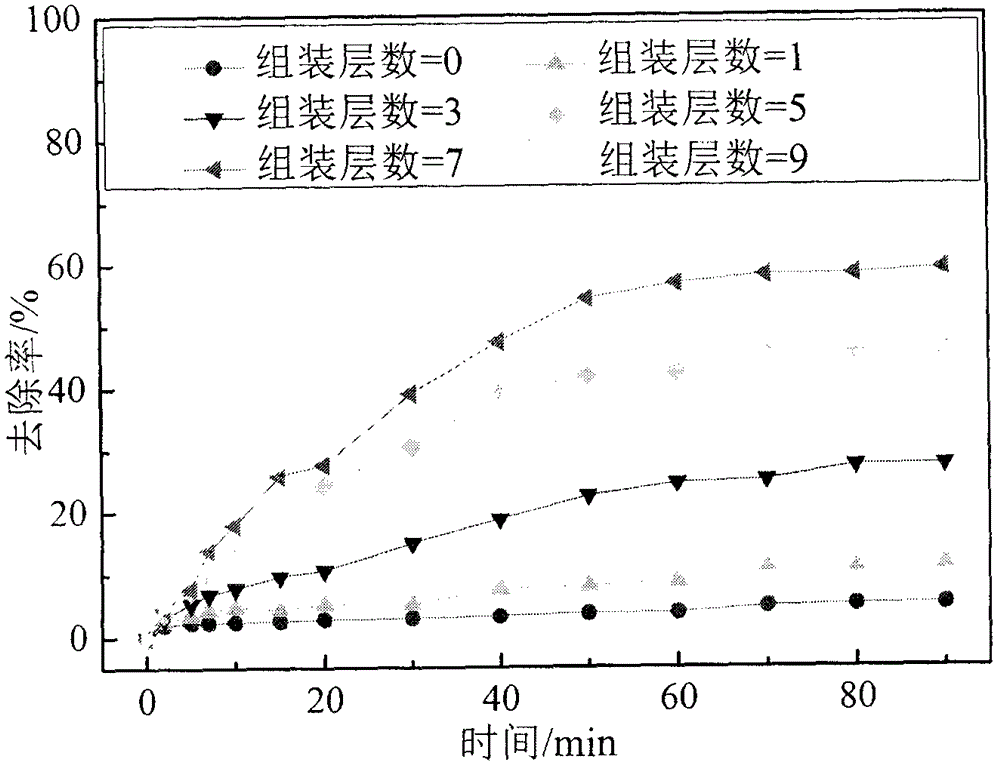

[0021] This example is to verify that the self-assembled metal coordination polymer catalytic membrane supports Fe 0 The effect of the amount on the reduction reaction of N-nitrosodimethylamine.

[0022] Add the prepared N-nitrosodimethylamine reaction solution with a concentration of 150 μg / L into a 50ml ground-mouth Erlenmeyer flask equipped with a rubber stopper, and perform magnetic stirring reaction on a multi-point intelligent magnetic stirrer. The temperature is 25° C., the rotational speed is 200 r / min, and the reaction solution is deoxidized by passing N2.

[0023] Adjust the initial pH value of the reaction solution to 6.5, add 0.42 g of self-assembled metal coordination polymer catalytic membranes with assembly layers of 1, 3, 5, 7, and 9, and use the method of measuring iron with o-phenanthroline to know the presence of iron in the membrane. The loads on the surface were 25.7mg / g, 77.6mg / g, 114mg / g, 151.7mg / g, 171.4mg / g respectively, and the reaction time was 1.5h...

Embodiment 2

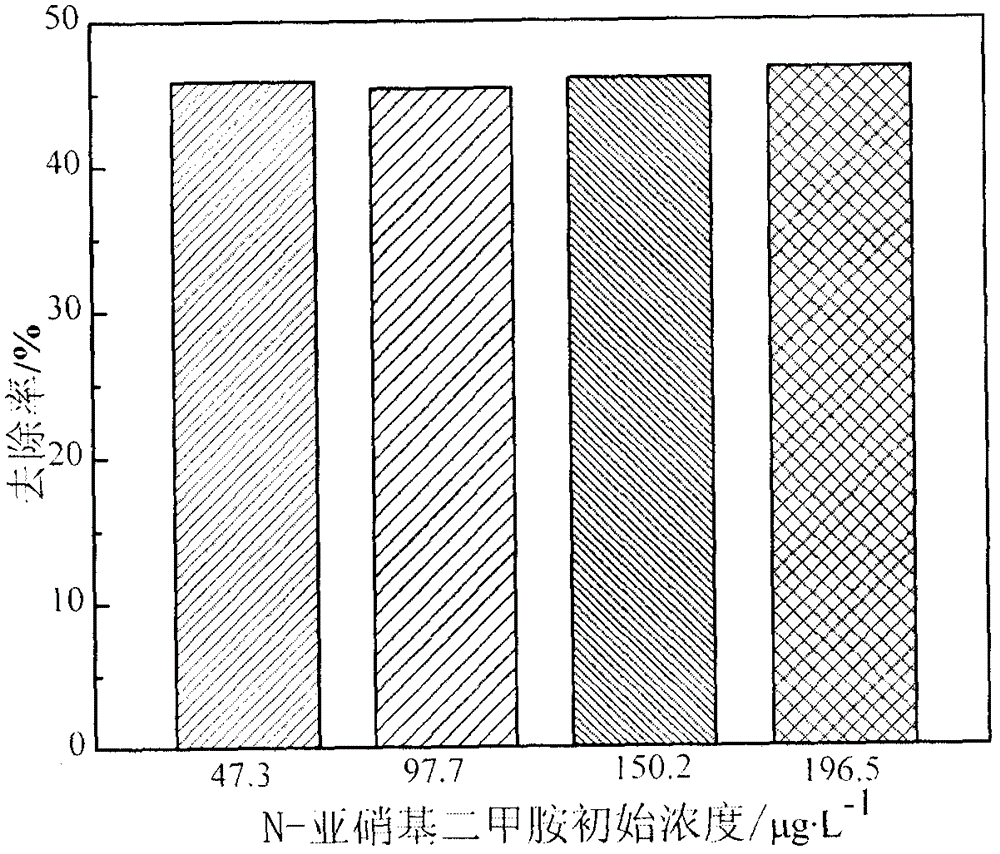

[0026] This example is to verify the effect of different initial concentrations of N-nitrosodimethylamine on the reduction reaction of N-nitrosodimethylamine.

[0027] Prepared N-nitrosodimethylamine reaction solutions with 4 concentrations of 47.3 μg / L, 97.7 μg / L, 150.2 μg / L, and 196.5 μg / L. Use four 50ml ground-mouth Erlenmeyer flasks equipped with rubber stoppers to add the prepared 4 kinds of concentration N-nitrosodimethylamine reaction solution, and the reaction solution is passed through N 2 Deoxidation treatment. The magnetic stirring reaction was carried out on a multi-point intelligent magnetic stirrer, the reaction temperature was 25° C., and the rotation speed was 200 r / min.

[0028]Adjust the initial pH value of the reaction solution to 6.5, add 0.42 g of a self-assembled metal coordination polymer catalytic membrane with 5 assembly layers in the reaction flask, the content of zero-valent iron on the surface of the composite membrane is 114 mg / g, and the reaction...

Embodiment 3

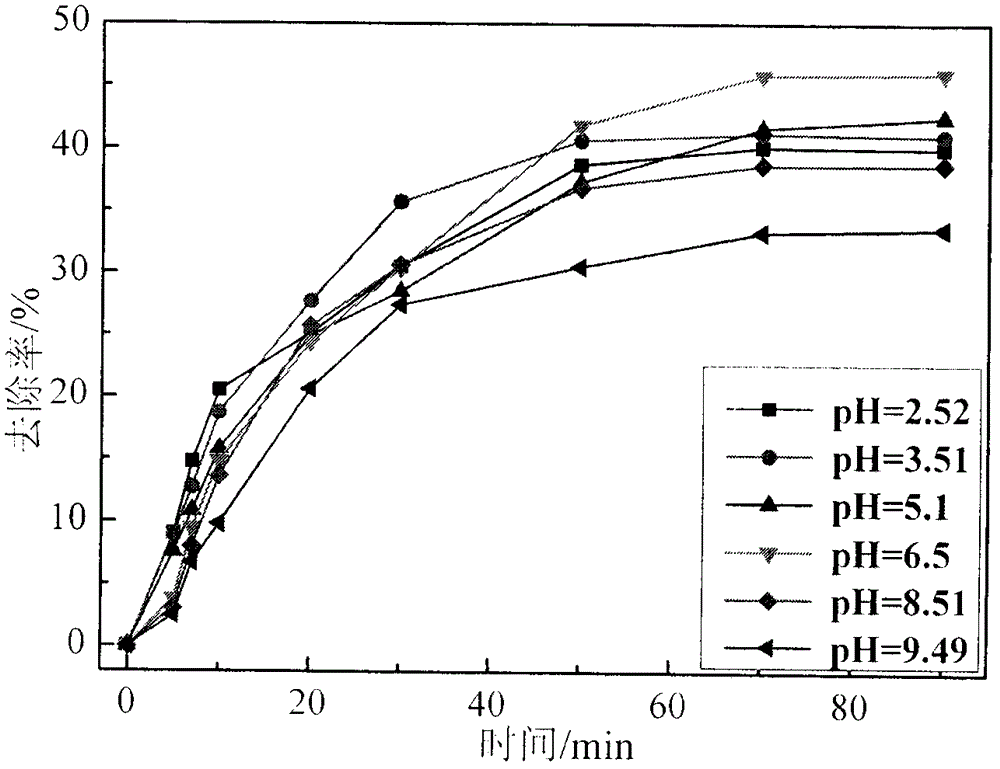

[0031] This example is to verify the effect of different initial pH values of solutions on the reduction reaction of N-nitrosodimethylamine.

[0032] Add the prepared N-nitrosodimethylamine reaction solution with a concentration of 150 μg / L into a 50ml ground-mouth Erlenmeyer flask equipped with a rubber stopper, and perform magnetic stirring reaction on a multi-point intelligent magnetic stirrer. The temperature is 25° C., the rotational speed is 200 r / min, and the reaction solution is deoxidized by passing N2.

[0033] Adjust the initial pH values of the reaction solution to 2.52, 3.51, 5.1, 6.5, 8.51, and 9.49 respectively, add 0.42 g of a self-assembled metal coordination polymer catalytic membrane with an assembly layer of 5 in the reaction flask, and zero-valent iron on the surface of the composite membrane The content is 114mg / g, and the reaction time is 1.5h. Waters e2695 high performance liquid chromatography was used to detect the concentration of N-nitrosodimet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com