Ceramic material and preparation method thereof

A technology of ceramic materials and powder materials, which is applied in the field of calcium silicate/saufen-feldspar-based composite biodegradable ceramic materials and its preparation, can solve the problems of low degradability of saufen-feldspar, and achieve easy popularization and application, simple preparation process, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

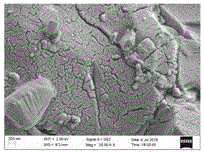

Image

Examples

specific Embodiment approach

[0020] A preparation method of a ceramic material, comprising the steps of:

[0021] Step 1) Preparation of ZnO–CaO–SiO 2 System sol-gel powder material;

[0022] In step 2), the powder material prepared in step 1) is put into a muffle furnace for heating and heat preservation. After the sintering is completed, the heating is stopped, and the furnace is cooled to obtain the in-situ calcium silicate / synthetic composite bioceramic material.

[0023] Step 1) The powder preparation method used is to use ethyl orthosilicate, calcium nitrate tetrahydrate and zinc nitrate hexahydrate as silicon source, calcium source and zinc source respectively. Zinc doping by sol-gel method to prepare ZnO–CaO–SiO 2 It is a sol. The sol is aged in a constant temperature water bath. After the gel is formed and dried in a drying oven, it is ball milled and sieved to obtain a powder. ZnO–CaO–SiO 2 The amount of ZnO added in the sol is 5-20mol%, ZnO–CaO–SiO 2 The diameter of the colloidal sol powde...

Embodiment 1

[0027] (1) Take 13.216g of calcium nitrate tetrahydrate, 5.94g of zinc nitrate hexahydrate and 25.84mL of ethyl orthosilicate by weight. First, tetraethyl orthosilicate was added to 23.76mL of water and 3.3mL of 2mol / L nitric acid solution was added as a catalyst for pre-hydrolysis for 60 minutes. During this period, the magnetic stirrer was used to stir continuously, and then the corresponding nitrates of calcium and zinc were added to stir respectively. After fully dissolving to form a sol, place it in a closed container at room temperature for a period of time, and after it forms a gel, place it in a constant temperature water bath at 60°C for aging treatment. Then place it in a drying oven and dry it at 120°C to obtain a xerogel, which is ball milled and sieved to obtain a powder with a particle size of 38-74 μm.

[0028] (2) Put the powder sample into the muffle furnace, raise the temperature from room temperature to 700°C at a heating rate of 5°C / min for stabilization tr...

Embodiment 2

[0030] (1) Take 15.576g of calcium nitrate tetrahydrate, 2.97g of zinc nitrate hexahydrate and 25.84mL of ethyl orthosilicate by weight. First, tetraethyl orthosilicate was added to 23.76mL of water and 3.3mL of 2mol / L nitric acid solution was added as a catalyst for pre-hydrolysis for 60 minutes. During this period, the magnetic stirrer was used to stir continuously, and then the corresponding nitrates of calcium and zinc were added to stir respectively. After fully dissolving to form a sol, place it in a closed container at room temperature for a period of time, and after it forms a gel, place it in a constant temperature water bath at 60°C for aging treatment. Then place it in a drying oven and dry it at 120°C to obtain a xerogel, which is ball milled and sieved to obtain a powder with a particle size of 38-74 μm.

[0031] (2) Put the powder sample into the muffle furnace, raise the temperature from room temperature to 700°C at a heating rate of 5°C / min for stabilization tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com