Selenium-rich compound microorganism fertilizer and preparation method thereof

A bio-fertilizer and selenium-enriched technology, applied in urea compound fertilizers, organic fertilizers, inorganic fertilizers, etc., can solve problems such as inability to improve soil compaction, and achieve the effects of prolonging crop shelf life, degrading heavy metals and pesticide residues, and improving crop quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

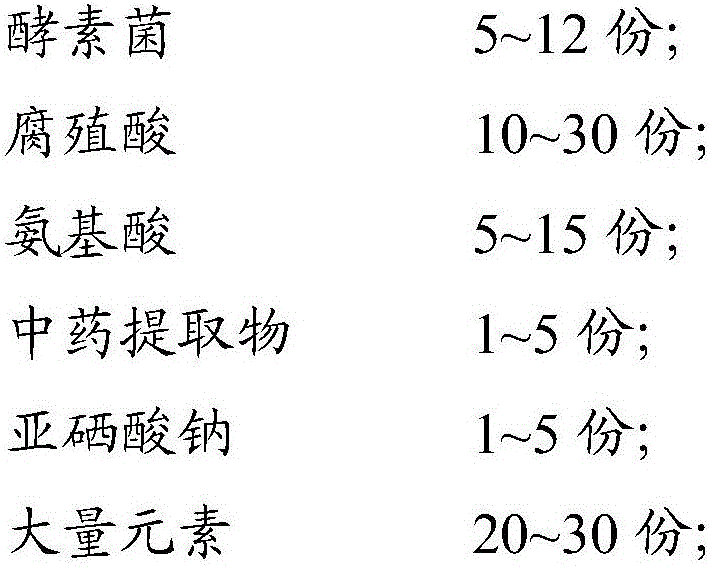

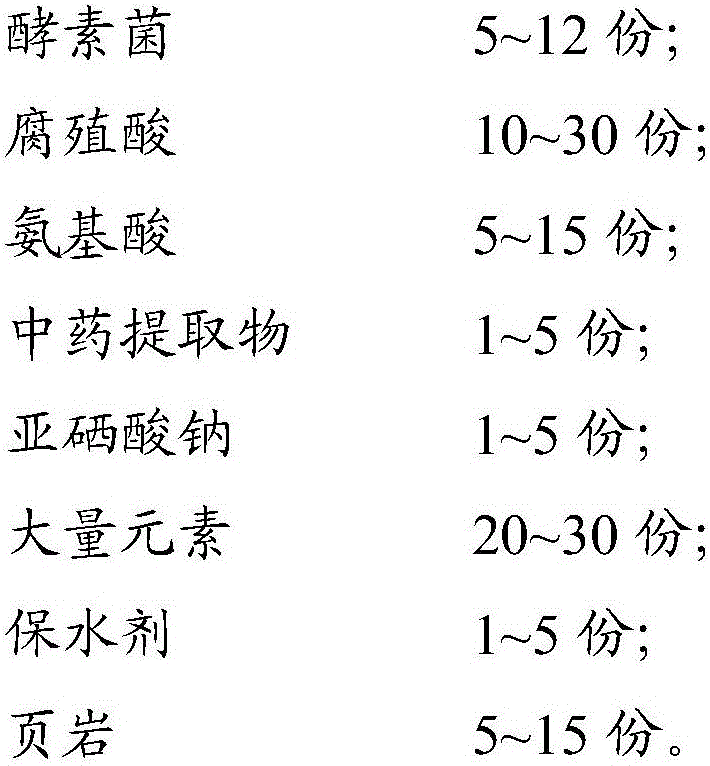

[0045] The present invention also provides a preparation method of selenium-enriched compound biological fertilizer, comprising the following steps:

[0046] a) Take humic acid, amino acid, Chinese medicine extract, sodium selenite, macroelements, water retaining agent and shale and put them into a grinder to grind and pulverize to obtain a mixture;

[0047] b) adding enzyme bacteria to the mixed material for fermentation treatment, the temperature during the fermentation process is 60-80° C., the fermentation time is 12-30 hours, and it can be granulated, packaged and put into storage.

[0048] The selenium-enriched compound microbial fertilizer prepared in the above technical solution can obviously activate the microorganisms in the soil, improve the metabolism of the microorganisms, increase the quantity of soil enzymes, and loosen the compacted soil. The fertilizer provided by the invention can also improve the soil, degrade heavy metals and pesticide residues in the soil ...

Embodiment 1

[0052] Take 30kg humic acid, 9kg amino acid, 0.67kg chrysanthemum brain extract, 1.33kg astragalus extract, 1.5kg sodium selenite, 8.56kg urea, 5.72kg ammonium dihydrogen phosphate, 5.72kg potassium sulfate, 1.5kg polypropylene Amide and 7kg shale are put into the grinder and ground and pulverized to obtain the mixture;

[0053] Then add 5 kg of potassium-dissolving active bacteria to the mixture for fermentation treatment, the temperature during the fermentation process is 60° C., and the time is 12 hours, then granulation, packaging and storage can be carried out.

Embodiment 2

[0055] Take 22kg humic acid, 10kg amino acid, 1kg chrysanthemum brain extract, 2kg astragalus extract, 1kg sodium selenite, 6.66kg urea, 6.66kg percarbamide, 4.33kg ammonium dihydrogen phosphate, 4kg diammonium hydrogen phosphate, 4.33kg of potassium chloride, 4kg of potassium nitrate, 1kg of sodium polyacrylate and 12kg of shale are put into a grinder for grinding and crushing to obtain a mixture;

[0056] Then add 12kg of phosphorus-solubilizing active bacteria to the mixture for fermentation treatment, the temperature during the fermentation process is 80°C, the time is 30h, and then granulation, packaging and storage can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com