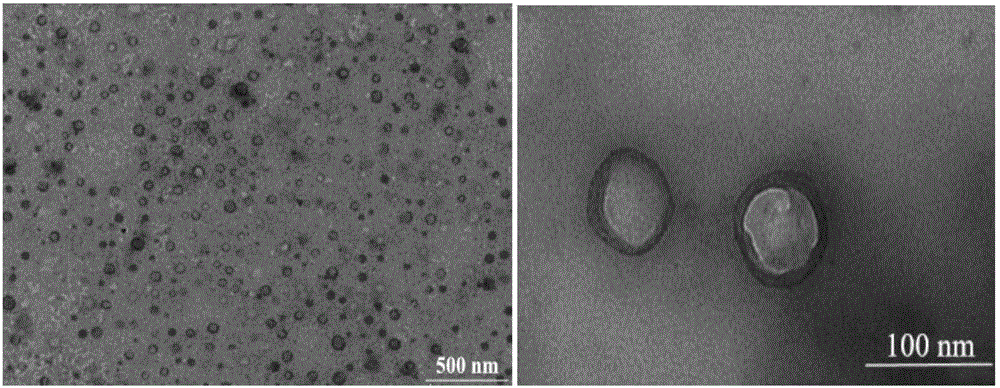

Preparation method of arabic gum hollow nanospheres

A kind of gum arabic and hollow nanotechnology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of poor compatibility between metal nanoparticles and shell materials, unfavorable compounds, environmental pollution, etc. , to achieve the effect of low cost, high repeatability and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

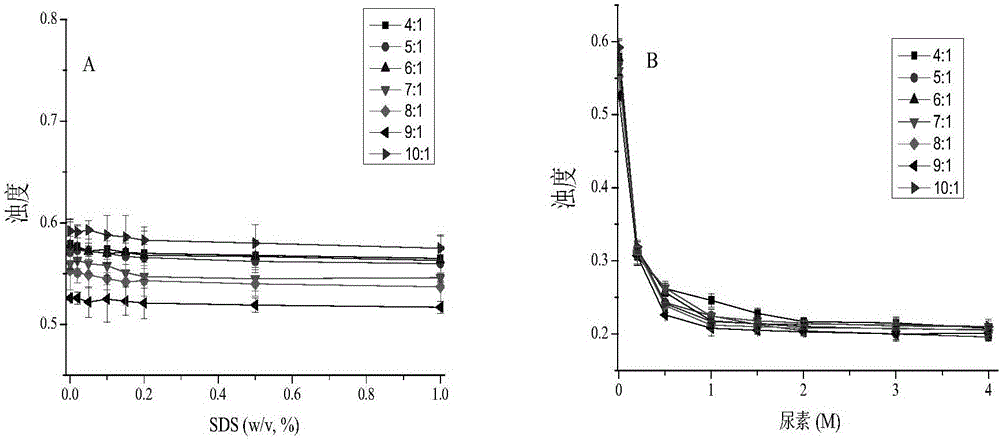

Examples

Embodiment 1

[0029] Prepare gum arabic hollow nanospheres with different shell-core ratios according to the following steps:

[0030] (1) Preparation of buffer solution: Accurately weigh 3.27g of disodium hydrogen phosphate and 2.24g of citric acid and dissolve them in 200mL of distilled water, stir to fully dissolve, and set aside;

[0031] (2) Pullulanase pretreatment: Accurately measure 1 mL of pullulanase with a concentration of 1350 NPUN / mL and drop it into 10 mL of distilled water, stir to make it fully mixed, and set aside;

[0032] (3) Preparation of starch milk: Weigh 15 g of waxy cornstarch and add it to 100 mL of buffer solution to obtain a starch emulsion with a mass volume ratio of 15%;

[0033] (4) Gelatinization: put the prepared starch milk in a water bath at 100°C for 20 minutes to completely gelatinize the starch, and then cool down to 58°C;

[0034] (5) Enzymolysis: add 1.5 mL of treated pullulanase to the gelatinized colloidal starch solution, and enzymatically hydroly...

Embodiment 2

[0066] (1) Preparation of buffer solution: Accurately weigh 1.635g of disodium hydrogen phosphate and 1.12g of citric acid and dissolve in 100mL of distilled water, stir to fully dissolve, and set aside;

[0067] (2) Pullulanase pretreatment: Accurately measure 1 mL of pullulanase with a concentration of 1350 NPUN / mL and drop it into 9 mL of distilled water, stir to make it fully mixed, and set aside;

[0068] (3) Preparation of starch milk: Weigh 10 g of waxy cornstarch and add it to 100 mL of buffer solution to prepare a starch emulsion with a mass volume ratio of 10%;

[0069] (4) Gelatinization: Put the prepared starch milk in a water bath at 100°C for 40 minutes to completely gelatinize the starch, then cool down to 55°C;

[0070] (5) Enzymolysis: add 1 mL of the treated pullulanase to the gelatinized colloidal starch solution, and enzymatically hydrolyze at 55°C for 6 hours;

[0071] (6) Low-speed centrifugation: centrifuge the solution obtained while hot at a speed of ...

Embodiment 3

[0079] (1) Preparation of buffer solution: Accurately weigh 6.54g of disodium hydrogen phosphate and 4.48g of citric acid and dissolve in 400mL of distilled water, stir to fully dissolve, and set aside;

[0080] (2) Pullulanase pretreatment: Accurately measure 1 mL of pullulanase with a concentration of 1350 NPUN / mL and drop it into 8 mL of distilled water, stir to make it fully mixed, and set aside;

[0081] (3) Preparation of starch milk: Weigh 20 g of waxy cornstarch and add it to 100 mL of buffer solution to obtain a starch emulsion with a mass volume ratio of 20%;

[0082] (4) Gelatinization: put the prepared starch milk in a water bath at 100°C for 50 minutes to completely gelatinize the starch, and then cool down to 60°C;

[0083] (5) Enzymolysis: add 2 mL of the treated pullulanase to the gelatinized colloidal starch solution, and enzymatically hydrolyze at 60°C for 6 hours;

[0084] (6) Low-speed centrifugation: centrifuge the solution obtained while hot at a speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com