Granular PLA modified material for FDM printing and preparation method thereof

A modified material, PLA technology, applied in the field of new environmentally friendly PLA modified materials and preparation, can solve problems such as hindering the development of the 3D printing industry, poor adhesion, deformation, etc., to improve resource utilization, improve mechanical properties, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

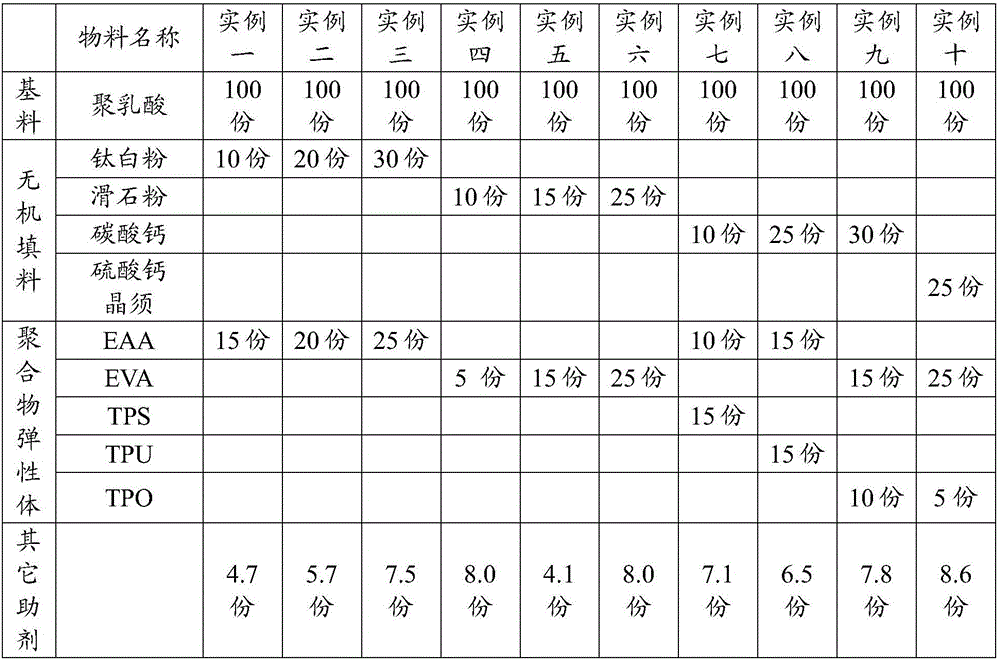

Examples

example 1

[0043] The other additives described in Example 1 are: 1 part of dioctyl phthalate, 1 part of polycaprolactone, 0.5 part of KH-550, 0.2 part of ADR, 0.3 part of a mixture of tetraerythritol ester and triphosphite, 0.5 parts of polycarbodiimide compound, 0.2 part of monocarbodiimide compound, 0.5 part of maleic anhydride grafted polymer, and 0.5 part of liquid paraffin.

example 2

[0044]Other additives described in Example 2 are respectively: 1 part of acetyl tributyl citrate, 1 part of polybutylene adipate, 1 part of KH-560, 0.2 part of ADR, mixture of tetraerythritol ester and triphosphite 0.5 part, 0.6 part of polycarbodiimide compound, 0.3 part of monocarbodiimide compound, 0.8 part of maleic anhydride grafted polymer, 0.3 part of zinc stearate.

example 3

[0045] Other additives described in Example 3 are: 1 part of tricresyl phosphate, 1 part of polybutylene succinate, 2 parts of titanic acid coupling agent, 0.2 part of ADR, 0.8 parts of tetraerythritol ester and triphosphite mixture 0.5 parts of polycarbodiimide compound, 0.5 part of monocarbodiimide compound, 1 part of maleic anhydride grafted polymer, and 0.5 part of polyethylene wax.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com