Flame-retardant liquid silicone rubber for fabric reinforcement

A technology of liquid silicone rubber and fabric reinforcement, applied in the direction of coating, etc., can solve problems such as polluting the environment, affecting the health of workers, and hidden dangers of unsafe production, achieving high surface friction, simple and easy preparation methods, and wide application range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

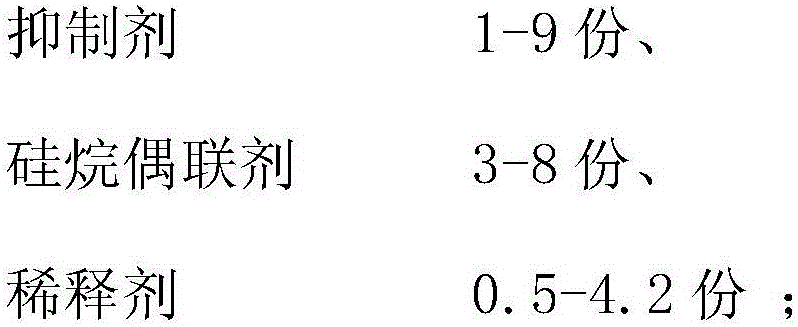

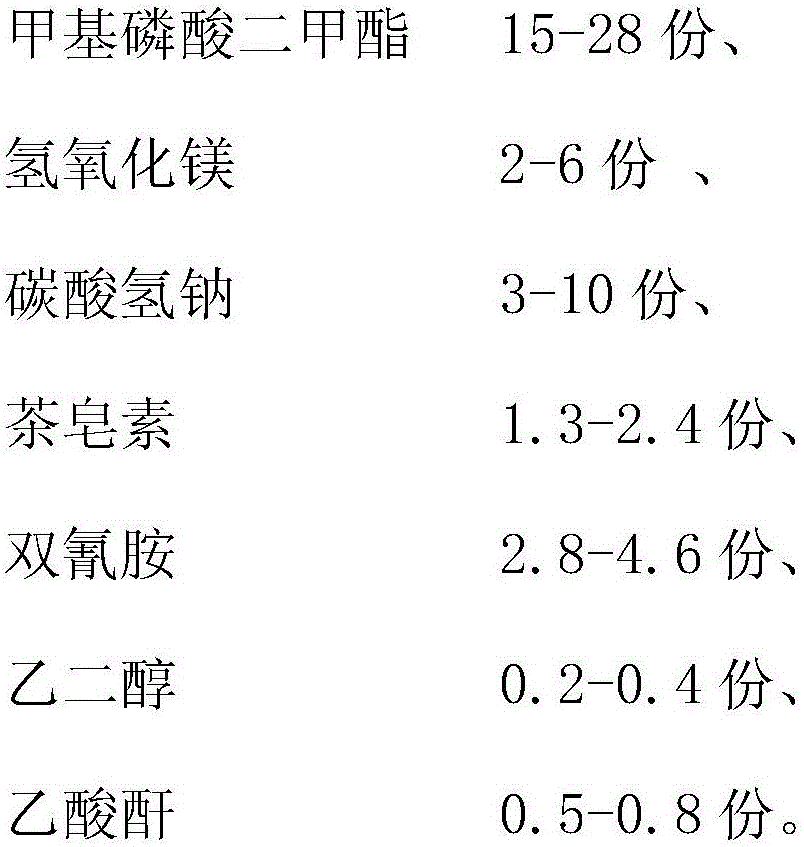

Method used

Image

Examples

Embodiment 1

[0032] A flame-retardant liquid silicone rubber for fabric reinforcement, the preparation method of which is:

[0033] (1) Preparation of base glue I: 35 parts of aminopolysiloxane with a viscosity of 8000cp measured at 25°C, 42 parts of aminopolysiloxane with a viscosity of 4000cp measured at 25°C, 11 parts of microsilica powder, and six parts by weight. Add 4 parts of sodium metaphosphate and 5 parts of absolute ethanol into the kneader, and knead for 4 hours at a temperature of 55°C;

[0034] (2) Preparation of Base II: In parts by weight, 20 parts of vinylpolysiloxane with a viscosity of 1500cp measured at 25°C, 40 parts of vinylpolysiloxane with a viscosity of 15000cp measured at 25°C, dicyclohexane Add 1.2 parts and 19 parts of silicon dioxide into the kneader, and knead for 1.5 hours at a temperature of 55°C;

[0035] (3) Preparation of component A: Add 120 parts of base glue I into the kneader in parts by weight, stir at 35°C for 1 hour, then raise the temperature to ...

Embodiment 2

[0040] A flame-retardant liquid silicone rubber for fabric reinforcement, the preparation method of which is:

[0041] (1) Preparation of Base I: 30 parts of aminopolysiloxane with a viscosity of 9000cp at 25°C, 48 parts of aminopolysiloxane with a viscosity of 3500cp at 25°C, 9 parts of silicon micropowder, and six parts by weight. Add 5 parts of sodium metaphosphate and 3 parts of absolute ethanol into the kneader, and knead for 4 hours at a temperature of 55°C;

[0042] (2) Preparation of Base II: In parts by weight, 18 parts of vinylpolysiloxane with a viscosity of 1800cp measured at 25°C, 45 parts of vinylpolysiloxane with a viscosity of 13000cp measured at 25°C, dicyclohexane Add 1.8 parts and 22 parts of silicon dioxide into the kneader, and knead for 1 hour at a temperature of 55°C;

[0043] (3) Preparation of component A: add 110 parts of base rubber I into the kneader by weight parts, stir at 35°C for 1.5h, then raise the temperature to 130°C, add 10 parts of tackif...

Embodiment 3

[0048] A flame-retardant liquid silicone rubber for fabric reinforcement, the preparation method of which is:

[0049] (1) Preparation of Base I: In parts by weight, 28 parts of aminopolysiloxane with a viscosity of 10000cp measured at 25°C, 35 parts of aminopolysiloxane with a viscosity of 5000cp measured at 25°C, 8 parts of microsilica powder, six Add 3 parts of sodium metaphosphate and 2 parts of absolute ethanol into the kneader, and knead for 3 hours at a temperature of 50°C;

[0050] (2) Preparation of Base II: In parts by weight, 15 parts of vinylpolysiloxane with a viscosity of 2000cp at 25°C, 30 parts of vinylpolysiloxane with a viscosity of 18000cp at 25°C, dicyclohexane Add 0.6 parts and 10 parts of silicon dioxide into the kneader, and knead at a temperature of 50°C for 1 hour;

[0051] (3) Preparation of component A: Add 100 parts of base glue I into the kneader in parts by weight, stir at 30°C for 1 hour, then raise the temperature to 120°C, add 5 parts of tacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com