Graphene zinc oxide polyester resin coating and preparation method thereof

A technology of polyester resin and zinc oxide, applied in polyester coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of high self-corrosion current density, affecting performance, poor coating effect, etc., and achieve uniform coating thickness , stable properties, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

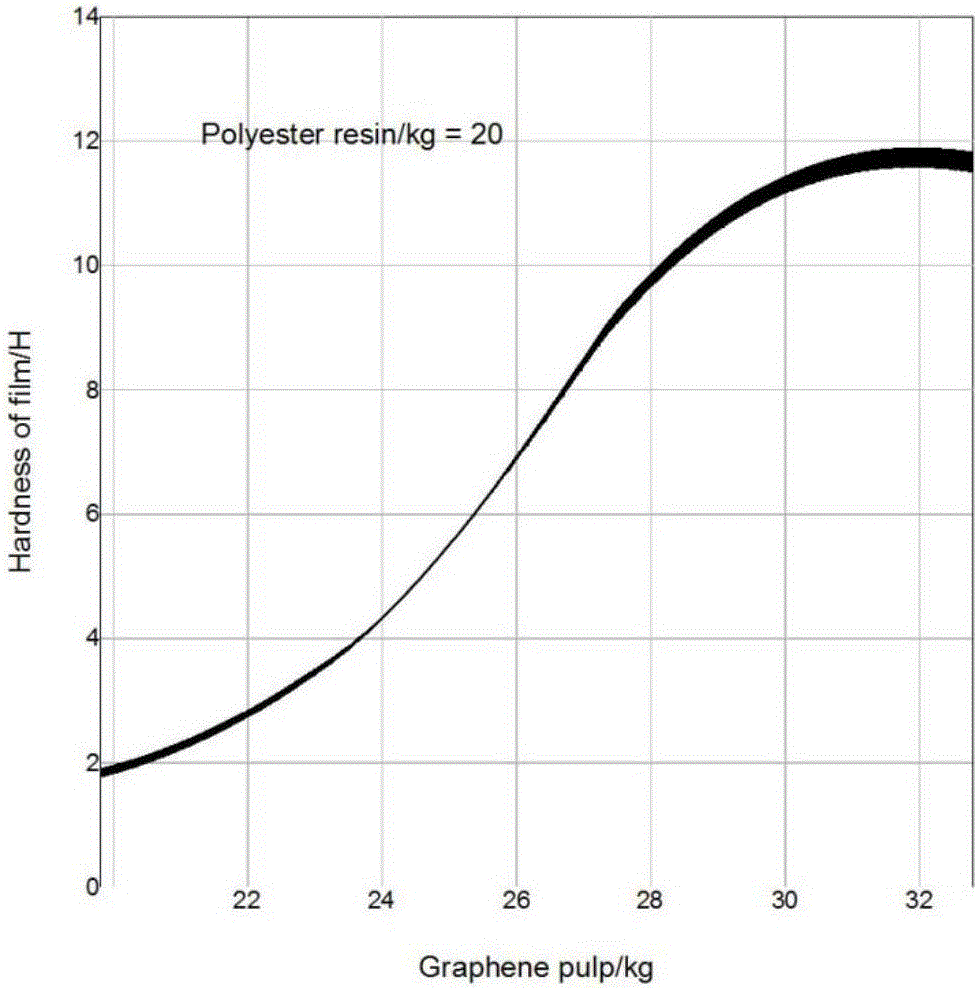

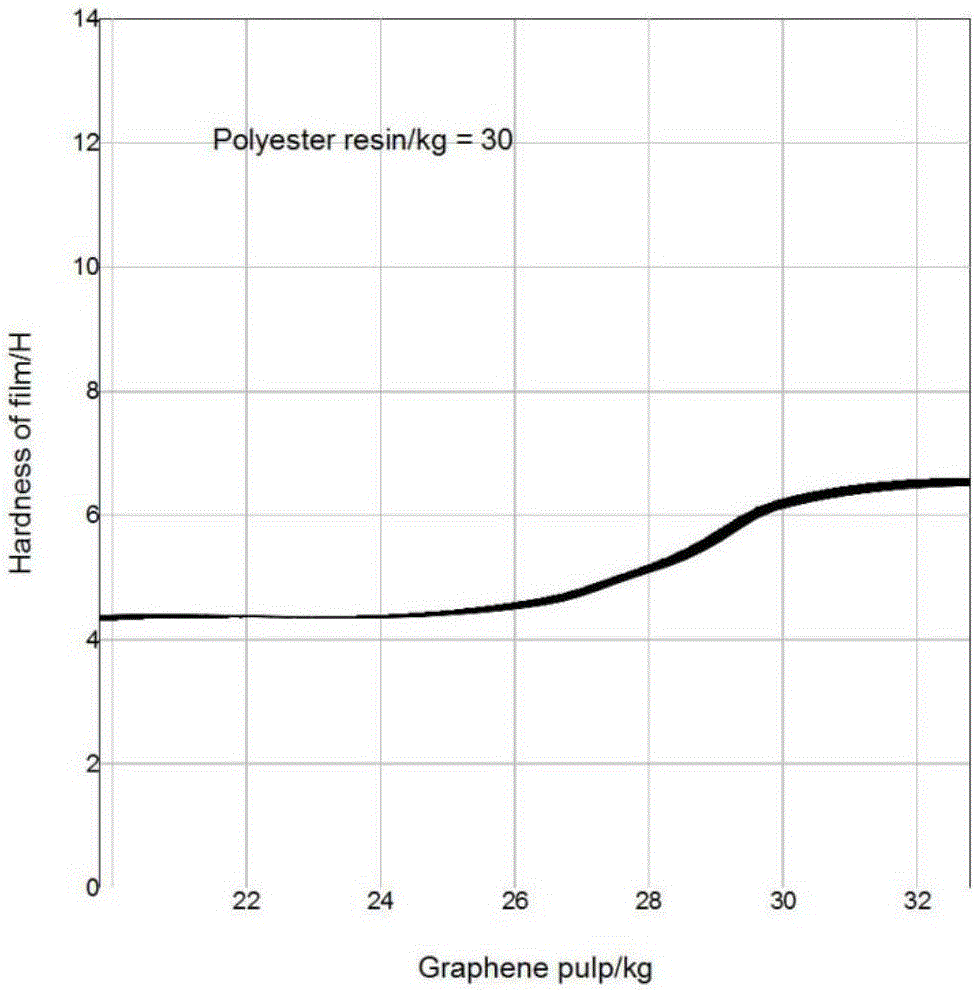

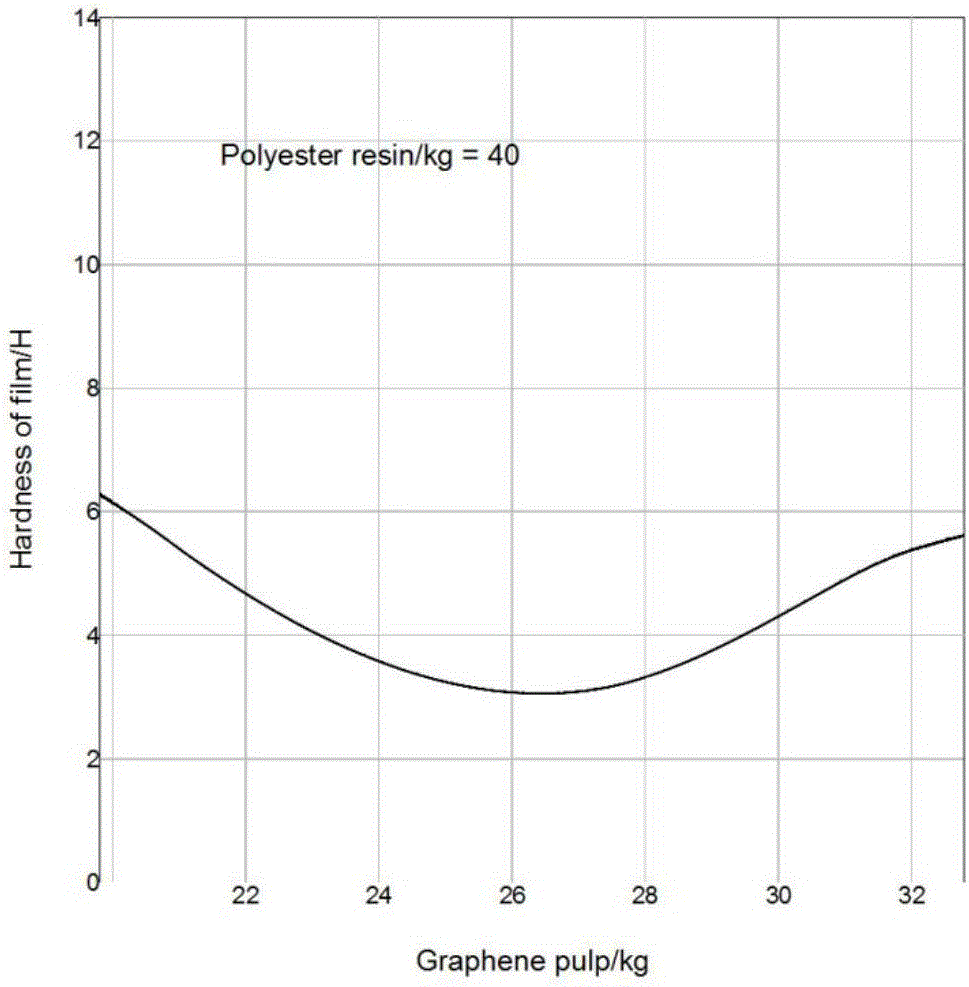

Image

Examples

Embodiment Construction

[0051] Firstly, graphene material No. 1-10 was prepared through experiments (1)-(10), with the purpose of finding out the best graphene slurry that can be compatible with the coating substrate polyester resin. The graphene powder used is produced by Jining Lite Nano Technology Co., Ltd.; the coupling modifier used refers to 3-aminopropyltriethoxysilane; the diluent used refers to n-butanol, xylene and ethanol according to the volume ratio of 1 :3:2 composition; the epoxy resin used refers to the bisphenol A epoxy resin produced by Anhui Shenjian New Materials Co., Ltd.

[0052] The following experimental design adopts the multi-factor and multi-level design method of independent research, covering 10 levels of ladder tests of four materials. It is a reasonable test arrangement with 4 factors and 10 levels to ensure the systematicness of the test.

[0053] Prepare graphene slurry, carry out following experiment (1)-(10):

[0054] (1) Preparation of graphene slurry No. 1

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion current | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com