Epoxy adhesive for motor of electric vehicle and preparation method of epoxy adhesive

An epoxy adhesive, electric vehicle technology, applied in the direction of adhesive, epoxy resin, adhesive type, etc., can solve the problem that the performance and quality cannot fully meet the requirements, achieve low linear expansion coefficient, and accelerate the improvement of technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

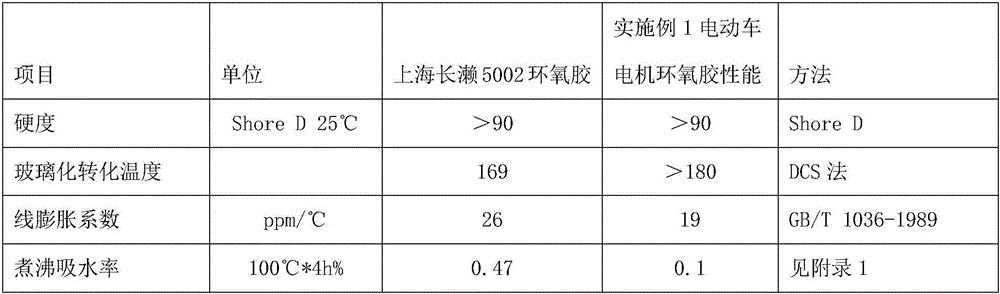

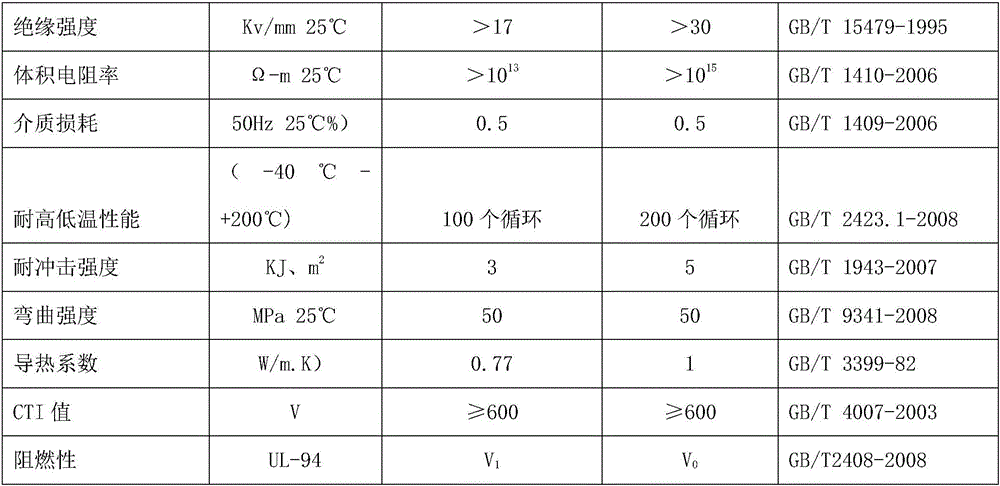

Embodiment 1

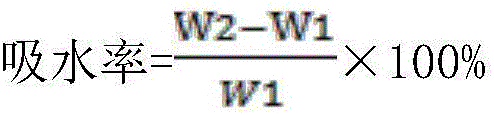

[0050] Weigh each component according to the following parts by mass, component A: 20 parts by mass of E-51 epoxy resin; 5 parts by mass of bis((3,4-epoxycyclohexyl) methyl) adipate; hydantoin 10 parts by mass of resin; 2 parts by mass of trihydroxymethylpropane glycidyl ether; 25 parts by mass of 20 μm spherical microsilica powder; 26.8 parts by mass of 27 μm spherical microsilica powder; 5 parts by mass of 1 μm aluminum hydroxide; ; 0.2 mass parts of defoamer; 0.5 mass parts of coupling agent; 2 mass parts of color paste; 3 mass parts of tripolychlorophosphazene; B component: 25 mass parts of hexahydroanhydride; 30 mass parts of spherical silica powder; 28.8 mass parts of 27 μm spherical silica powder; 1 mass part of 2-hexyl-4-methylimidazole; 0.2 mass parts of phosphite antioxidant (TNP); 5 mass parts of 1 μm aluminum hydroxide;

[0051] According to each component weighed above, the epoxy resin adhesive is prepared by the following method:

[0052] Prepare component A and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com