Mesoporous-aluminosilicate-based shaping phase change material prepared from fly ash and preparation method thereof

A technology of phase change materials and aluminosilicates, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of fly ash dependence and restrict the development of traditional energy industries, and achieve continuous load, low leakage rate, High heat storage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

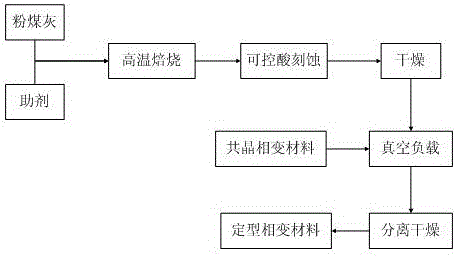

[0036] Such as figure 1 As shown, a method for preparing an aluminosilicate-based phase change material prepared by fly ash of the present invention comprises steps:

[0037] Step 1): Mix fly ash with one or more of carbonates, hydroxides or oxides of alkali metals or alkaline earth metals, then roast at high temperature, and rapidly cool the roasted products;

[0038] Step 2): Grinding the quenched roasted sample prepared in step 1) and performing solid-liquid reaction with acid solution;

[0039] Step 3): After the solid-liquid reaction is completed, the solid powder obtained by solid-liquid separation is dried to obtain a mesoporous aluminosilicate powder;

[0040] Step 4): Put the mesoporous aluminosilicate powder prepared in step 3) under vacuum conditions, and maintain the same temperature as the phase transition temperature of the supported phase change material, and then fill with excess phase in molten state Change the material, make the mixture, and continue to mai...

Embodiment 1

[0045] Step 1): Sodium carbonate and fly ash are mixed according to the mass ratio of 30:100, then roasted at 870°C for 45 minutes, and the roasted product is quenched;

[0046] Step 2): Grind the quenched roasted sample powder prepared in step 1) and react with 20% HCl acid solution at 25°C for 15 minutes;

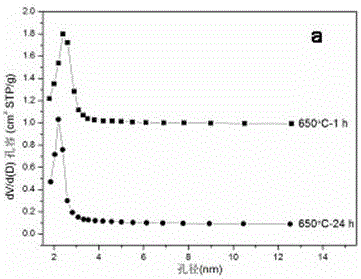

[0047]Step 3): After the solid-liquid reaction is completed, the solid powder obtained by solid-liquid separation is dried to obtain a mesoporous aluminosilicate powder with wedge-shaped pores, and the molar ratio of aluminum and silicon in the obtained product is 0.7:1;

[0048] Step 4): The wedge-shaped mesoporous aluminosilicate powder prepared in step 3) was placed under a vacuum condition of 30kPa, and maintained in contact with the loaded phase change materials lauric acid, myristic acid and stearic acid (LA- PA-SA) The eutectic phase transition temperature is 31.76°C at the same temperature, then filled with excess lauric acid in the molten state, the mixture was p...

Embodiment 2

[0052] Mix 1 part of calcium carbonate with 0.5 part of sodium hydroxide, mix the mixture with fly ash at a mass ratio of 50:100, and then roast at 1150°C for 60 minutes to quench the roasted product;

[0053] Step 2): Grind the quenched roasted sample powder prepared in step 1) and react with 20% HCl acid solution at 60°C for 60 minutes;

[0054] Step 3): After the solid-liquid reaction is completed, the solid powder obtained by solid-liquid separation is dried, and the product obtained with a molar ratio of aluminum to silicon of about 4:1 is screened to obtain mesoporous aluminum-silicon with flat-shaped pores Salt powder;

[0055] Step 4): Place the plate-shaped porous mesoporous aluminosilicate powder prepared in step 3) under a vacuum condition of 80kPa, and maintain the eutectic phase transition temperature of lauric acid and myristic acid with the loaded phase change material at 33.62 °C at the same temperature, and then filled with an excess of molten lauric acid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com