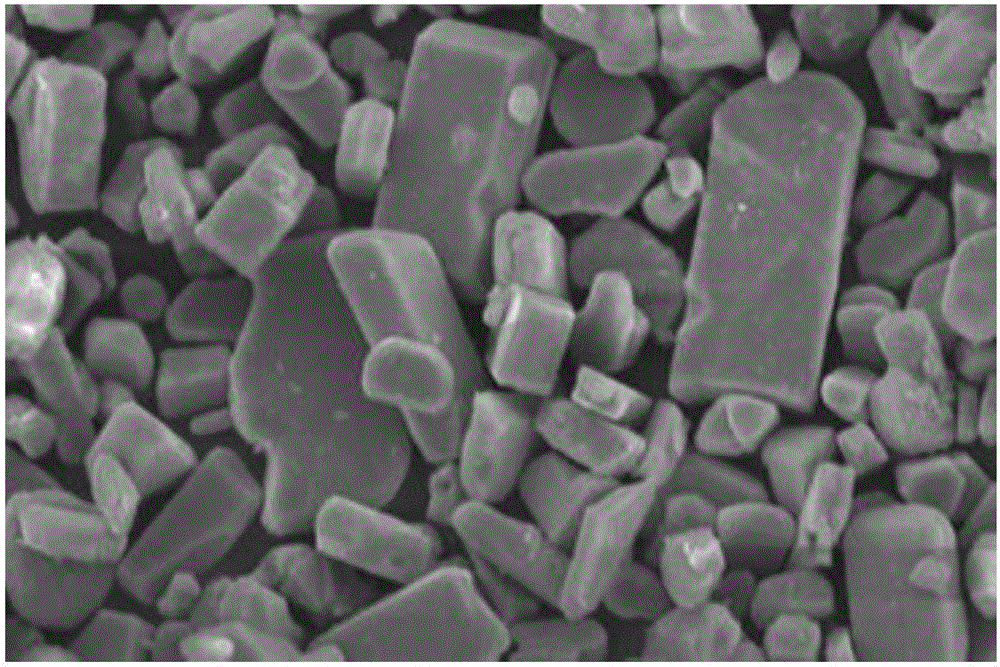

Red fluorescence powder with high color rendering and low light attenuation and preparation method thereof

A red fluorescent powder, high color rendering technology, applied in chemical instruments and methods, luminescent materials, gaseous chemical plating, etc., to achieve the effect of improving color rendering, high luminous efficiency, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1Sr 0.890 Ca 0.100 SiAlN 3 Cl 0.110 f 0.030 : Eu 0.01

[0061] Step (1): According to the chemical formula Sr 0.890 Ca 0.100 SiAlN 3 Cl 0.110 f 0.030 : Eu 0.01 The stoichiometric ratio weighs 46.37 grams of strontium nitride, 2.66 grams of calcium nitride, 22.03 grams of aluminum nitride, 25.13 grams of silicon nitride, 0.6 grams of ammonium fluoride, 2.10 grams of ammonium chloride, and 1.12 grams of europium oxide;

[0062] Step (2): Fully mix the above raw materials evenly under nitrogen protection with a purity of 99.999%;

[0063] Step (3): Seal the uniformly mixed raw materials into a molybdenum crucible, cover and seal it, and burn it in stages under a pressure of 0.8Mpa in a nitrogen protection atmosphere with a purity of 99.999%: normal temperature (the normal temperature of the present invention is 25° C.) After reaching 1000°C, burn at a constant temperature of 1000°C for 5 hours, then rise to 1400°C for 5 hours, and finally rise to 1800°C...

Embodiment 1-3

[0076] Step (1): According to the chemical formula Sr 0.890 Ca 0.100 SiAlN 3 f 0.030 : Eu 0.010 The stoichiometric ratio weighs 46.37 grams of strontium nitride, 2.66 grams of calcium nitride, 22.03 grams of aluminum nitride, 25.13 grams of silicon nitride, 0.6 grams of ammonium fluoride, and 1.12 grams of europium oxide;

[0077] Step (2): Fully mix the above raw materials evenly under nitrogen protection with a purity of 99.999%;

[0078] Step (3): Seal the uniformly mixed raw materials into a molybdenum crucible, cover and seal it, and burn it in stages in a nitrogen protective atmosphere with a purity of 99.999% and a pressure of 0.8Mpa: raise the temperature from normal temperature to 1000°C and keep the temperature for 5 hours. Keep the temperature at 1400°C for 5 hours, and finally rise to 1800°C for 8 hours. After cooling to room temperature, take out the red blocky powder;

[0079] Step (4): The red blocky powder is milled with agate balls for 2 hours, and passed...

Embodiment 2

[0083] Example 2Sr 0.868 Ca 0.112 SiAlN 3 Cl 0.100 f 0.030 : Eu 0.02

[0084] Step (1): According to the chemical formula Sr 0.868 Ca 0.112 SiAlN 3 Cl 0.100 f 0.030 : Eu 0.02 The stoichiometric ratio weighs 45.18 grams of strontium nitride, 2.97 grams of calcium nitride, 22.00 grams of aluminum nitride, 25.10 grams of silicon nitride, 0.6 grams of ammonium fluoride, 1.91 grams of ammonium chloride, and 2.24 grams of europium oxide;

[0085] Step (2): Fully mix the above raw materials evenly under nitrogen protection with a purity of 99.999%;

[0086] Step (3): Put the uniformly mixed raw materials into a molybdenum crucible, cover and seal it tightly, and burn in stages in a nitrogen protection atmosphere with a purity of 99.999% and a pressure of 0.9Mpa: raise the temperature from normal temperature to 800°C and burn at a constant temperature for 6 hours , and then raised to 1300°C for 5 hours at a constant temperature, and finally raised to 1800°C for 8.5 hours a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com