A kind of surface modified castor fiber and its preparation method and application

A technology of surface modification and castor, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of weak adhesion, poor interface bonding between castor fiber and resin matrix, etc., and achieve outstanding toughness and enhancement The effect of strong interface binding ability, adhesion and chelating force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

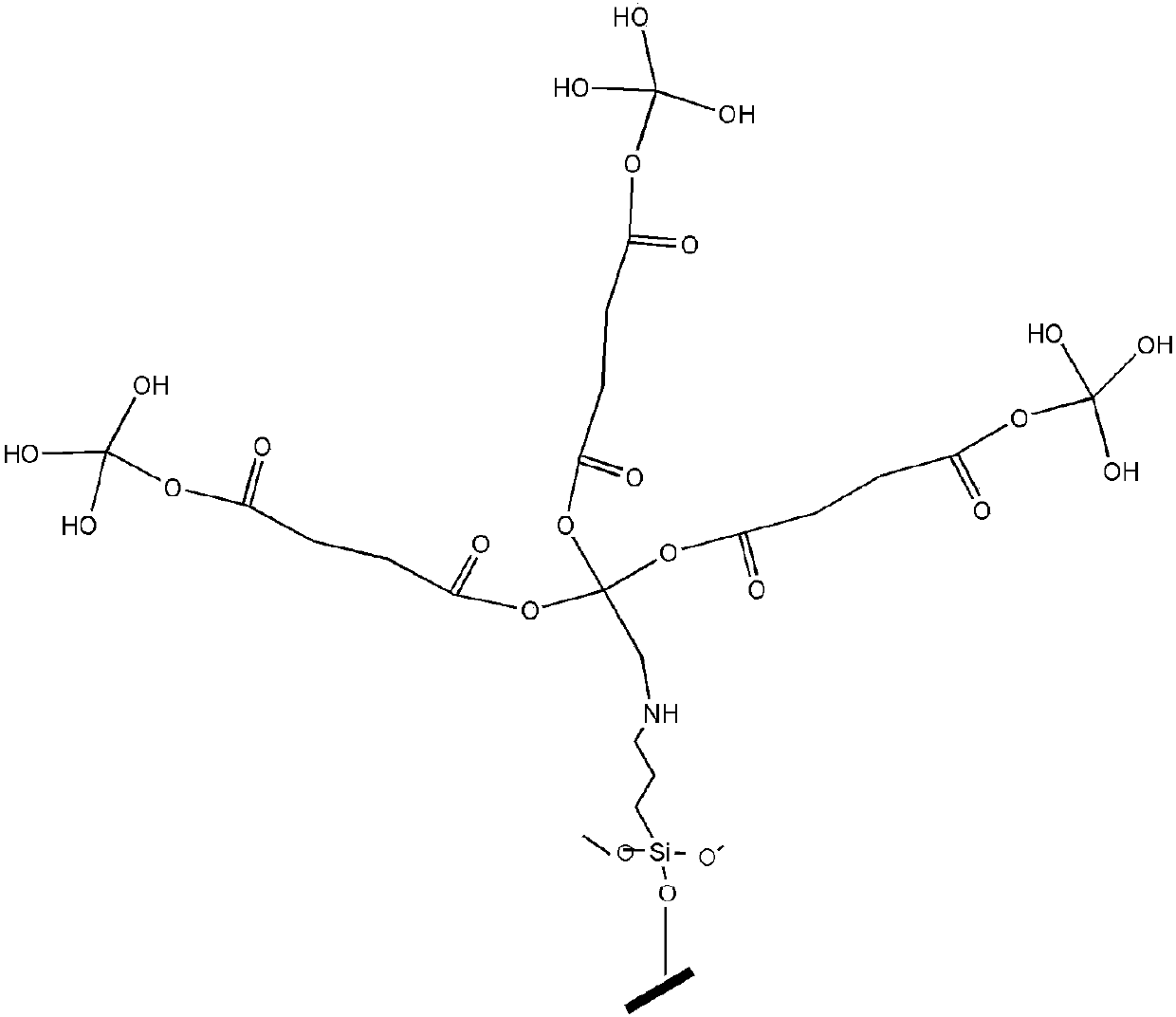

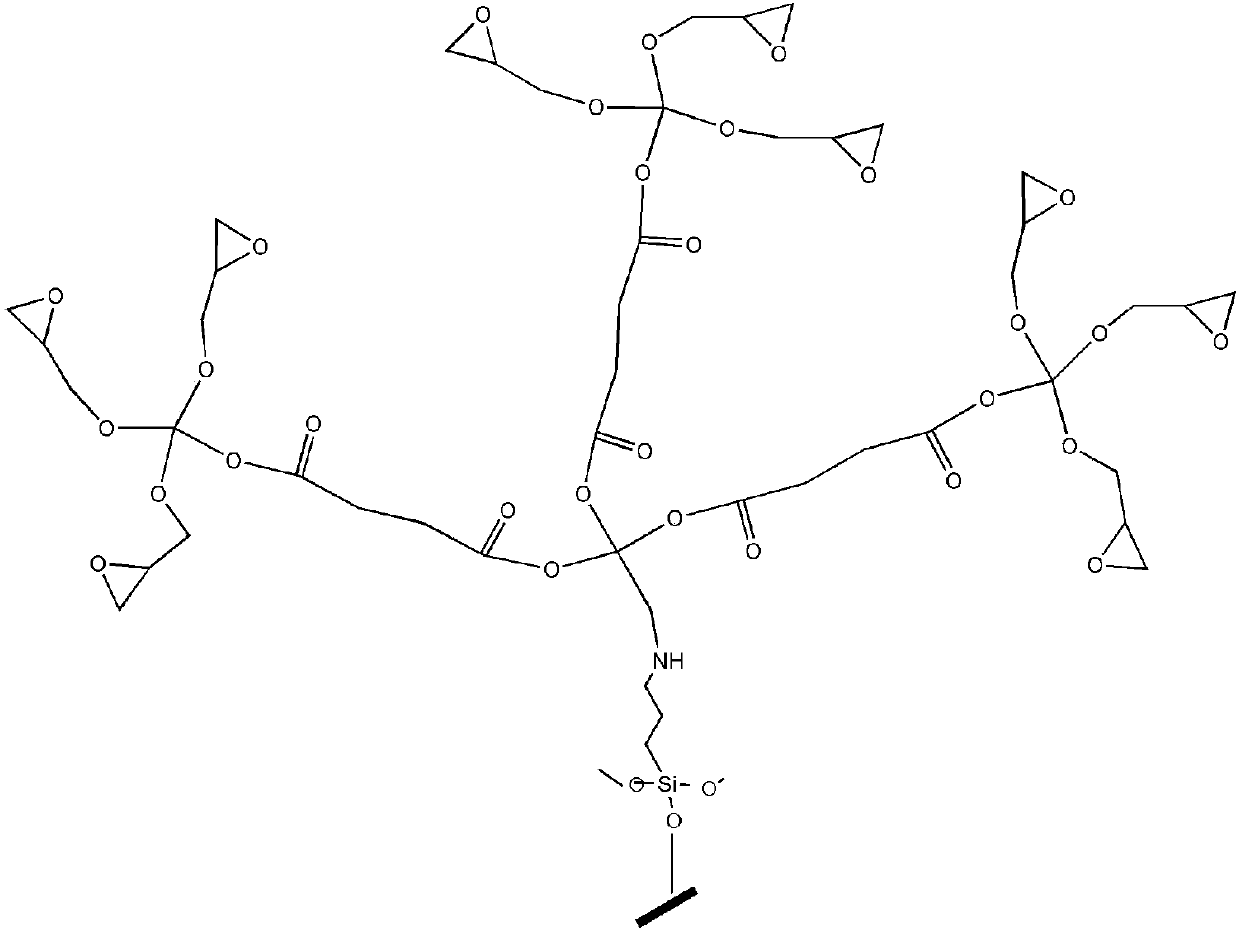

[0029] The preparation method of this surface-modified castor-oil fiber comprises the following steps: first castor-oil fiber is carried out silanization treatment; Then by polycondensation reaction graft terminal hydroxyl hyperbranched polymer on castor-oil fiber surface, its molecular structural formula is as follows figure 1 , and finally end-capping with an epoxy-based capping agent to obtain a surface-modified castor fiber, the molecular structure of which is as follows figure 2 .

[0030] The castor fiber with a length of 30-80 μm is selected as a raw material, and the surface-modified castor fiber obtained after modification has a constant length and a diameter of 10-15 μm.

Embodiment 1

[0032] (1) Preparation of surface modified castor fiber

[0033] Take 1g of castor fiber and add it to 17.4g of toluene, heat up to 80°C, then add dropwise 0.5g of 3-aminopropyltriethoxysilane, react for 6h, filter and dry to obtain silanized castor fiber. Weigh 1g of silanized castor fiber and add it to 9.45g of N,N-dimethylformamide, add 2.0g of succinic anhydride and 2.8g of pentaerythritol, heat up to 120°C, polymerize for 4 hours, and then add 15.0g of epichlorohydrin , The polymer was reacted at 110°C for 4 hours, and the surface-modified castor fiber was obtained after washing and drying.

[0034] image 3 Scanning electron micrographs of the prepared surface-modified castor fibers. Depend on image 3 It can be clearly seen that the epoxy-terminated hyperbranched polymer is grafted on the surface of the castor fiber, and the diameter of the surface-modified castor fiber is 10-15 μm.

[0035] (2) Reinforced and toughened bisphenol A diglycidyl ether epoxy resin with ...

Embodiment 2

[0038] (1) Preparation of surface modified castor fiber

[0039]Take 1g of castor fiber and add it to 17.4g of toluene, heat up to 80°C, then add 1.0g of 3-aminopropyltriethoxysilane dropwise, react for 6h, filter and dry to obtain silanized castor fiber. Weigh 1g of silanized castor fiber and add it to 9.45g of N,N-dimethylformamide, add 2.0g of succinic anhydride and 2.8g of pentaerythritol, heat up to 120°C, polymerize for 6 hours, and then add 20.0g of epichlorohydrin , The polymer was reacted at 110°C for 6 hours, and the surface-modified castor fiber was obtained after washing and drying.

[0040] (2) Reinforced and toughened bisphenol A diglycidyl ether epoxy resin with surface modified castor fiber

[0041] Take 6g of the above-mentioned modified castor fiber, add 100g of bisphenol A diglycidyl ether epoxy resin E51 and 35g of diethyltoluenediamine into the mixed system, and stir evenly. The curing conditions are 120°C / 2h+140°C / 2h+160°C / 2h. Measure its tensile stren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com