Preparation of CNTs/S-Cu2O for Electrochemical Detection of Glucose by Monovalent Copper Hydrolysis

A technology of s-cu2o and hydrolysis method, which is applied in the field of CNTs/S-Cu2O composite materials, can solve the problems of difficult control of material particle size, slow response speed and low accuracy, achieve good response speed, improve conductivity, increase The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

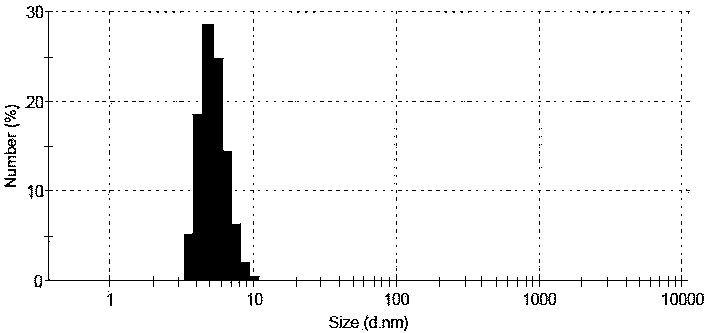

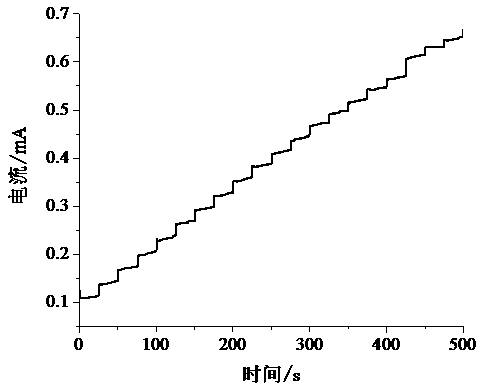

[0017] Specific implementation mode 1: CNTs / S-Cu for the electrochemical detection of glucose prepared by monovalent copper hydrolysis method in this implementation mode 2 OProceed as follows:

[0018] (1) Preparation of acidic monovalent copper solution: a. Weigh respectively according to the quality of catechol is 10~30 mg, the quality of thiourea is 0.2~2.0 g, and the quality of auxiliary complexing agent is 0.1~2.0 g Catechol, thiourea and auxiliary complexing agent; then add 50 mL of deionized water in sequence, stir until dissolved, adjust the pH to 5.0~6.5 with ammonia water or hydrochloric acid to obtain solution A; b. Slowly add 0.01 ~0.5 g of cuprous chloride, stirred until dissolved and aged for 12~36 h to obtain an acidic monovalent cupric solution;

[0019] (2) Preparation of CNTs aqueous solution: c. Add 0.01~0.6 g of CNTs to 50 ml of sulfuric acid + nitric acid mixed solution, stir at room temperature for 1~5 h, then sonicate for 1~3 h, then heat up to 95~120 °...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the auxiliary complexing agent described in step (1) a is one of citric acid, malic acid, tartaric acid or lactic acid or a combination of two of them , with a mass of 0.2~1.5 g / L. Others are the same as in the first embodiment.

[0024] When the auxiliary complexing agent of this embodiment is a composition, two auxiliary complexing agents are combined in arbitrary ratios.

specific Embodiment approach 3

[0025] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the volume ratio of sulfuric acid and nitric acid in the sulfuric acid+nitric acid mixed solution described in c of step (2) is 0.3-3.0. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com