Milk beta-casein content checking method

A detection method, casein technology, applied in the direction of measuring devices, material analysis by electromagnetic means, instruments, etc., can solve the problems of high price of coated capillary columns, long separation time of capillary columns, harsh use environment requirements, etc., to achieve centrifugal Good separation effect, increase in separation absorbance value, and the effect of low environmental requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

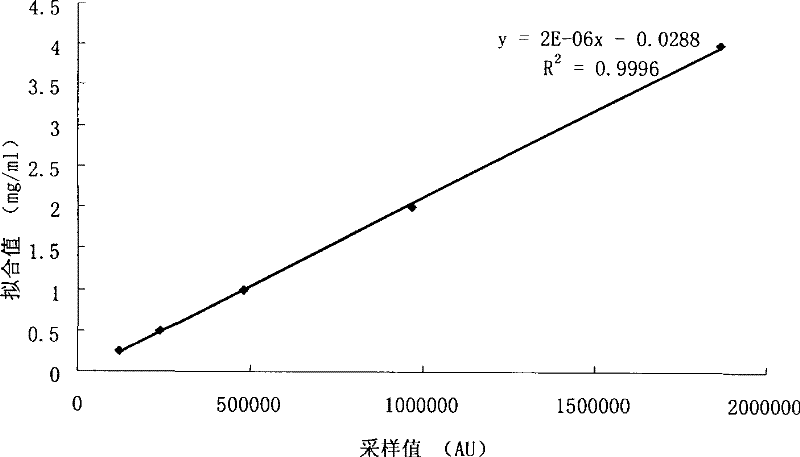

[0041] Example 1 Detection of β-casein content in milk (using coated quartz capillary column)

[0042] 1. Configuration of sample buffer: Add 40mmol / L 3-morpholinopropanesulfonic acid, 60mmol / L disodium ethylenediaminetetraacetic acid, 7mol / L urea to 160mmol / L trimethylaminomethane buffer solution to process the sample Add 5 ul / ml of β-mercaptoethanol, 0.05% methyl hydroxyethyl cellulose, and use 0.1M sodium hydroxide solution to adjust the pH value to 8.5.

[0043] 2. Configuration of electrophoresis buffer: 0.32mol / L citric acid, 20mmol / L trisodium citrate, 7mol / L urea, 0.05% hydroxypropyl methylcellulose.

[0044] 3. High-pressure capillary electrophoresis instrument (Beckman Coulter, P / ACE MDQ), detection parameters: the detection temperature is controlled at 30°C, a coated quartz capillary column with a diameter of 50 μm and a length of 20 mm is used, and a diode array detector (DAD detector), pressure injection, the injection pressure is 0.5psi, the injection time is 5s...

Embodiment 2

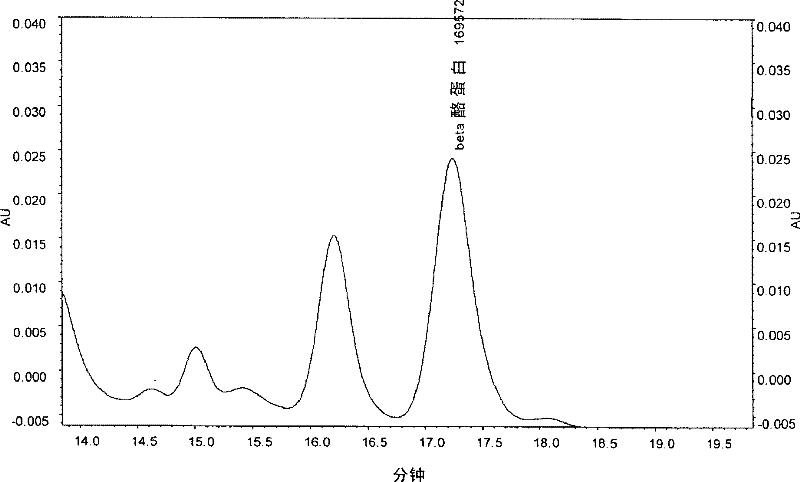

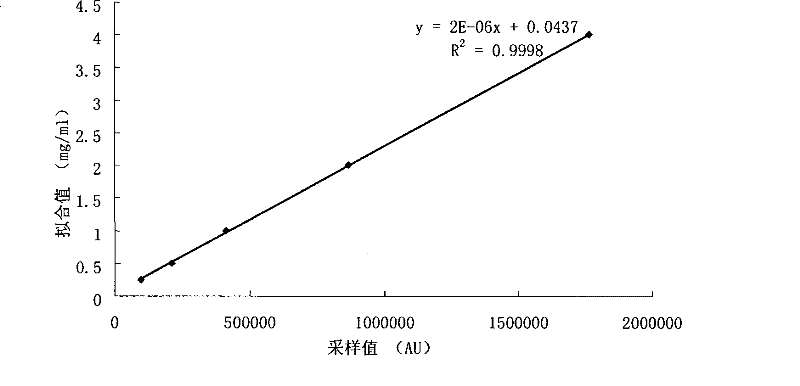

[0048] Example 2 Detection of β-casein content in milk (using uncoated quartz capillary column)

[0049] 1. Configuration of sample buffer: add 40mmol / L 3-morpholinopropanesulfonic acid, 60mmol / L disodium ethylenediaminetetraacetic acid, 7mol / L urea to 160mmol / L trimethylaminomethane buffer solution, when processing samples Add 5ul / ml of β-mercaptoethanol, 0.05% of methyl hydroxyethyl cellulose. The pH was adjusted to 8.5 using 0.1 M sodium hydroxide.

[0050] 2. Configuration of electrophoresis buffer: 0.32mol / L citric acid, 20mmol / L trisodium citrate, 7mol / L urea, 0.05% hydroxypropyl methylcellulose.

[0051] 3. Capillary electrophoresis instrument (Beckman Coulter, P / ACE MDQ), detection parameters: the detection temperature is controlled at 30°C, using an uncoated quartz capillary column with a diameter of 75 μm and a length of 600 mm, a DAD detector, and pressure sample, the injection pressure is 0.5psi, the injection time is 5s, and the working voltage is 25kV.

[0052...

Embodiment 3

[0055] Example 3 A detection method for β-casein content in pasteurized milk

[0056] Use the same sample buffer, electrophoresis buffer, and high-pressure capillary electrophoresis instrument as in Example 1, and use the same instrument detection parameters as in Example 1. The standard curve obtained in Example 1 was used.

[0057] The sample processing and detection steps are as follows: add the pasteurized milk sample into a 15ml centrifuge tube, and centrifuge at 4500r / min for 10min. Accurately extract 100ul of the supernatant of the pasteurized milk sample after centrifugation and put it into a freezing tube (or other container). Extract 300ul of sample buffer into cryovials (or other containers), and use a vortex mixer to mix. Accurately extract 40ul processed samples and add them into sample tubes, place them in an ultrasonic cleaner for 3 minutes, and then measure them with a capillary electrophoresis instrument.

[0058] Quantitative reading of the sample: after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com