Rapid screening method of thermoelectric material with optimized performance

A thermoelectric material and performance technology, applied in the measurement of electricity, measurement of electrical variables, measurement devices, etc., can solve the problems of long experimental cycle, low efficiency, large workload, etc., to shorten the preparation cycle, simplify the synthesis process, improve the density and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] A method for rapidly screening Bi-Sb-Te-based high-performance thermoelectric materials, the specific steps are as follows:

[0028] 1) Using high-purity Sb block (6N), Bi block (6N) and Te block (6N) as starting materials, according to the stoichiometric ratio Bi 2 Te 3 , Sb 2 Te 3 For batching, put them in quartz glass tubes and vacuum seal them, then put them into a vertical melting furnace for reaction, heat up at a rate of 4°C / min, keep at 800°C for 6h, and get an ingot after cooling with the furnace;

[0029] 2) Grind the ingot to get powder, weigh 4g Sb 2 Te 3 The single-phase powder is put into a graphite mold with a diameter of 12.7mm and then sintered in a plasma-activated sintering equipment. The vacuum condition is below 10Pa, the pressure is 30MPa, the temperature is 500℃, and the holding time is 5min to obtain a dense block;

[0030] 3) Put 4g Bi 2 Te 3 The powder is poured pre-loaded with Sb 2 Te 3 The block is re-sintered in a graphite mold with...

Embodiment 1

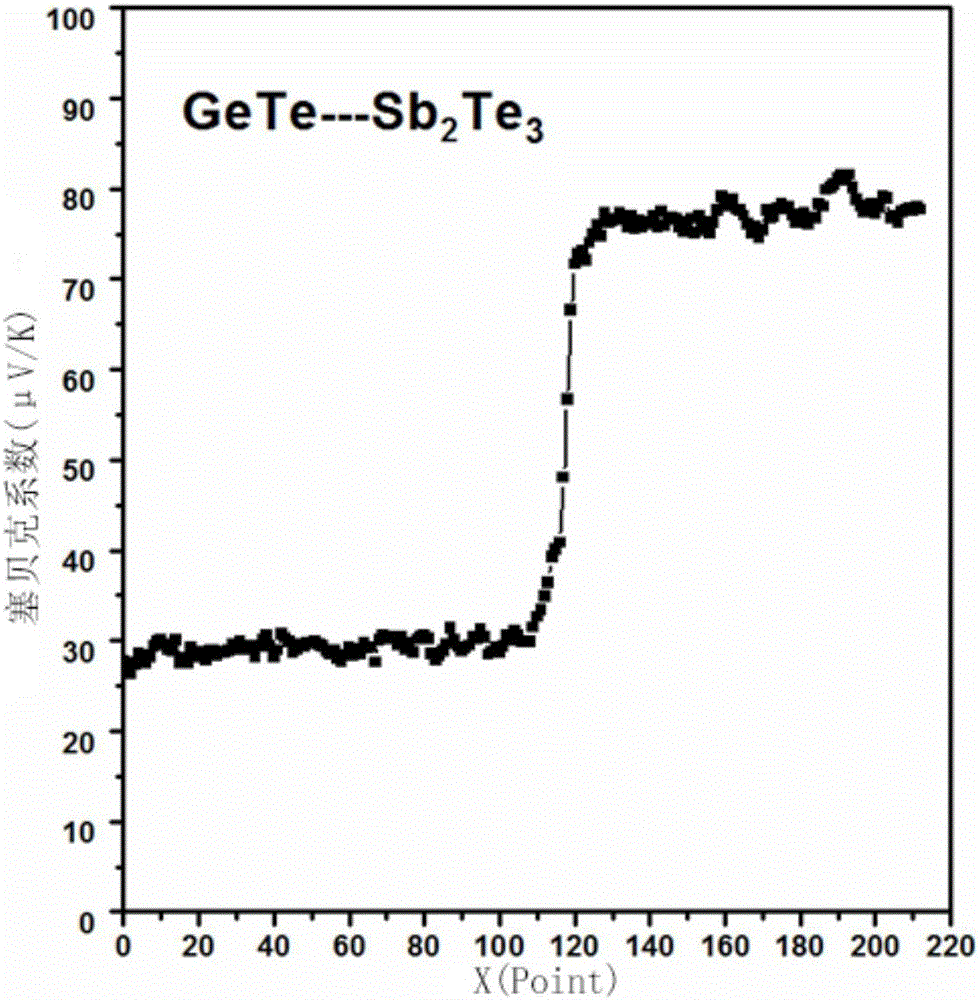

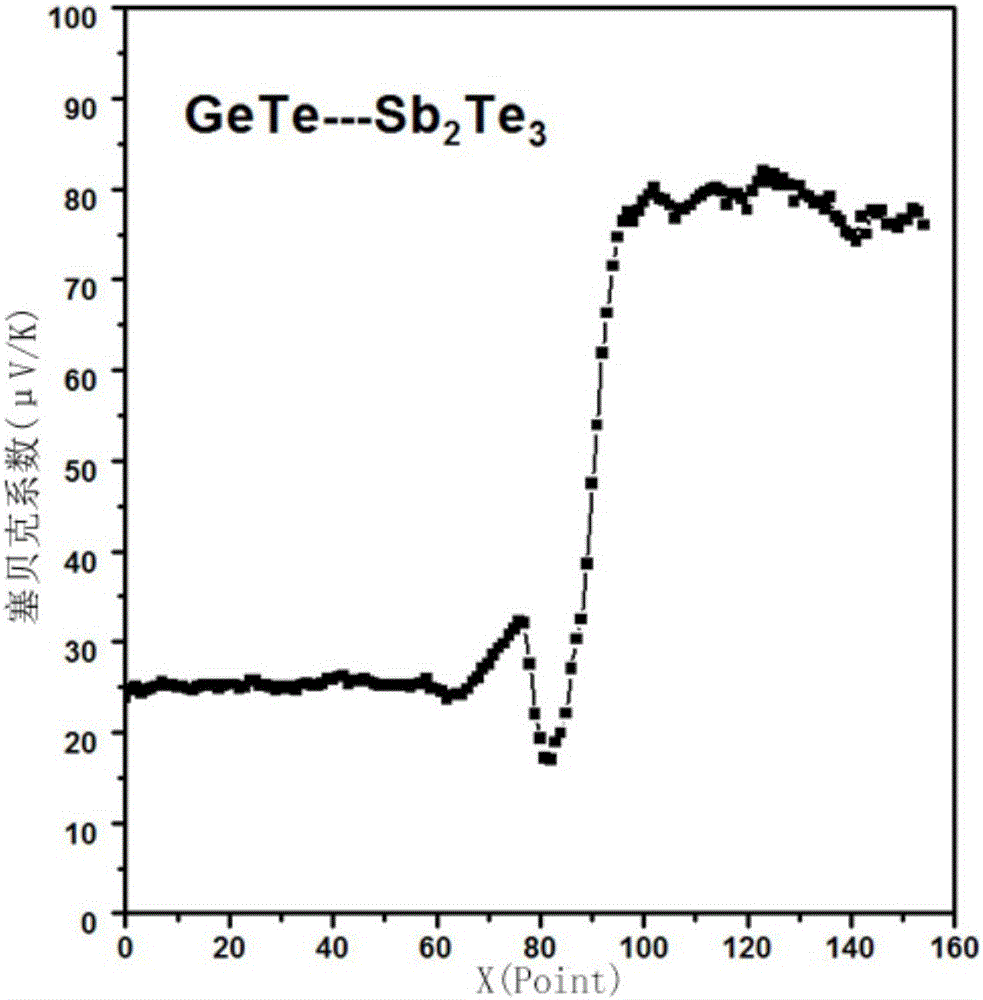

[0041] Based on the above exploration, the present invention provides a rapid screening GeTe-Sb 2 Te 3 The method for thermoelectric materials with system performance optimization, the specific steps are as follows:

[0042] 1) Using high-purity Ge blocks (4N), Sb blocks (6N), Te blocks (6N) as starting materials, according to GeTe, Sb 2 Te 3 The stoichiometric ratio is used for batching, and the obtained batches are respectively placed in quartz glass tubes and then vacuum-sealed, and then put into a vertical melting furnace for reaction. For the GeTe compound, after 4 hours, it is raised to 1000 ° C, and after 20 hours of heat preservation, then Furnace cooling to obtain a GeTe compound ingot, for Sb 2 Te 3 The compound was raised to 750°C after 3 hours, kept for 10 hours and then cooled with the furnace to obtain Sb 2 Te 3 compound ingot;

[0043] 2) The resulting GeTe compound ingot and Sb 2 Te 3 The compound ingots were ground into powder respectively, and 4g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com