A kind of high mobility transistor and its preparation method

A high-mobility, transistor-based technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of lack of inverters, etc., and achieve the effect of good manufacturing process compatibility and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

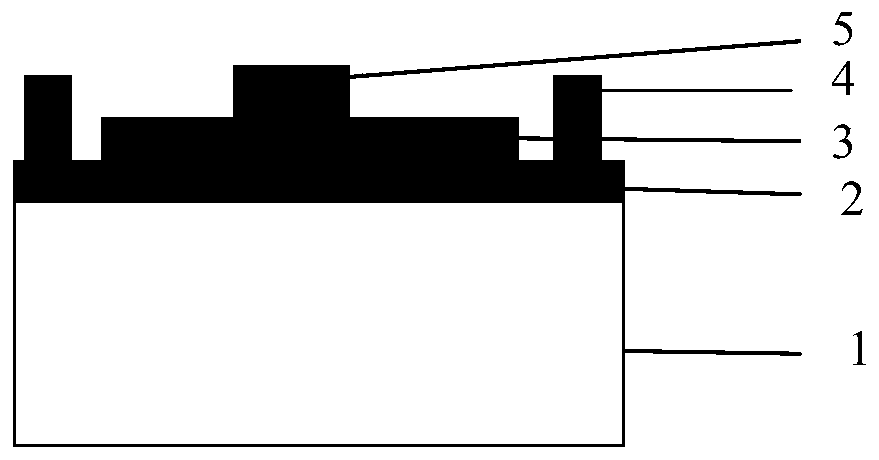

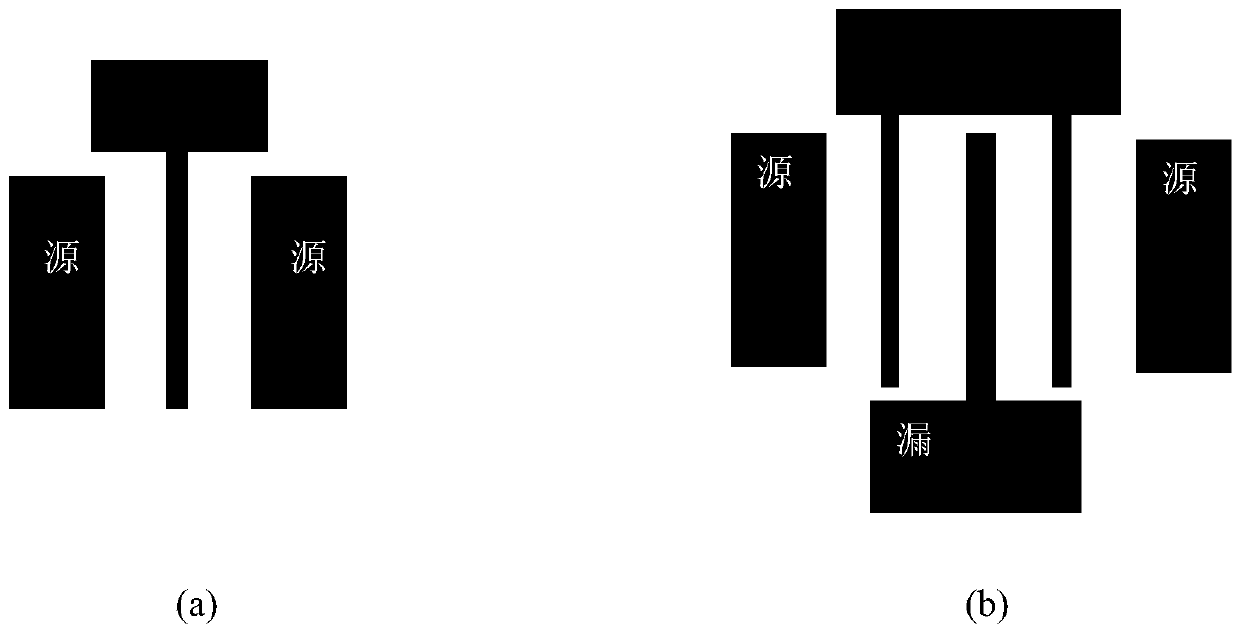

[0030] Implementation example 1: GaN-based HEMT with P-type graphene channel

[0031] (1) Preparation of GaN epitaxial layer

[0032] The MOCVD method uses organic compounds of group III elements and hydrides of group V elements as raw materials, and is brought into the reaction chamber by a carrier gas such as hydrogen or nitrogen to epitaxially form compound single crystal thin films on a substrate heated at high temperature. The growth of GaN material is the epitaxial growth of GaN thin layer realized by the chemical reaction of Ga decomposed by TMGa and the cracked N atoms of NH3 at high temperature. The growth of GaN requires precise control of the growth temperature and the flow rate and partial pressure of NH3, and the flow rate of TMGa and other parameters. The commonly used methods are conventional MOCVD (including APMOCVD, LPMOCVD), plasma enhanced MOCVD (PE-MOCVD) and electron cyclotron resonance assisted MBE. Sapphire substrate cleaning: (H 2 SO 4 :H 3 Etch in...

Embodiment 2

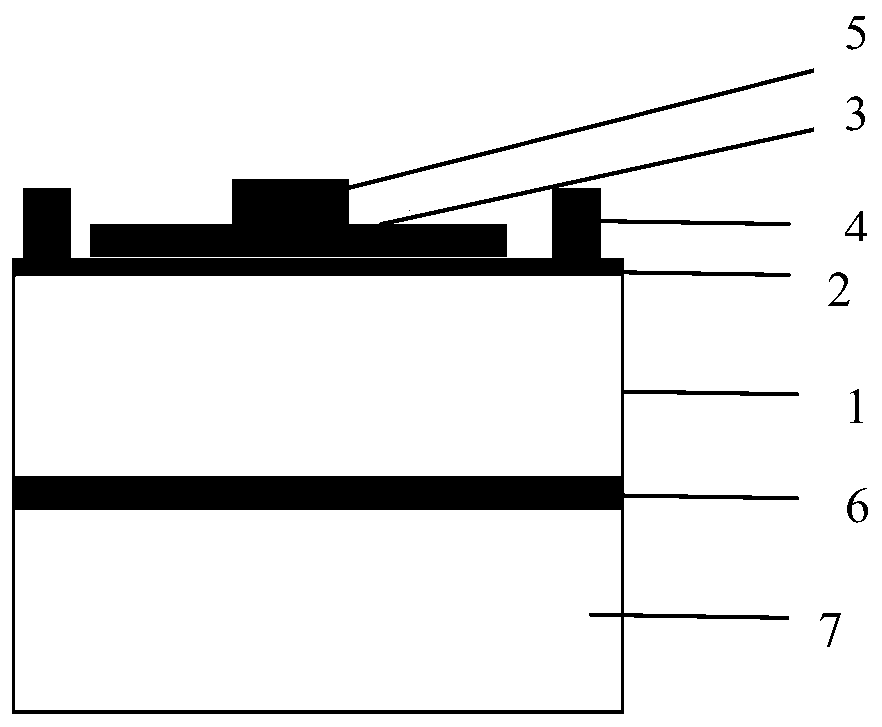

[0042] Implementation example 2: GaN-based HEMT with N-type graphene channel

[0043] (1) Preparation of GaN epitaxial layer

[0044] The MOCVD method uses organic compounds of group III elements and hydrides of group V elements as raw materials, and is brought into the reaction chamber by a carrier gas such as hydrogen or nitrogen to epitaxially form compound single crystal thin films on a substrate heated at high temperature. The growth of GaN material is the epitaxial growth of GaN thin layer realized by the chemical reaction of Ga decomposed by TMGa and the cracked N atoms of NH3 at high temperature. The growth of GaN requires precise control of the growth temperature and the flow rate and partial pressure of NH3, and the flow rate of TMGa and other parameters. The commonly used methods are conventional MOCVD (including APMOCVD, LPMOCVD), plasma enhanced MOCVD (PE-MOCVD) and electron cyclotron resonance assisted MBE. Sapphire substrate cleaning: (H 2 SO 4 :H 3 Etch in...

Embodiment 3

[0054] Implementation example three: AlN-based P-type-graphene channel HEMT

[0055] (1) Preparation of AlN epitaxial layer

[0056] The MOCVD method uses organic compounds of group III elements and hydrides of group V elements as raw materials, and is brought into the reaction chamber by a carrier gas such as hydrogen or nitrogen to epitaxially form compound single crystal thin films on a substrate heated at high temperature. The growth of GaN material is the epitaxial growth of GaN thin layer realized by the chemical reaction of Ga decomposed by TMGa and the cracked N atoms of NH3 at high temperature. The growth of GaN requires precise control of the growth temperature and the flow rate and partial pressure of NH3, and the flow rate of TMGa and other parameters. The commonly used methods are conventional MOCVD (including APMOCVD, LPMOCVD), plasma enhanced MOCVD (PE-MOCVD) and electron cyclotron resonance assisted MBE. Sapphire substrate cleaning: (H 2 SO 4 :H 3Etch in P...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com