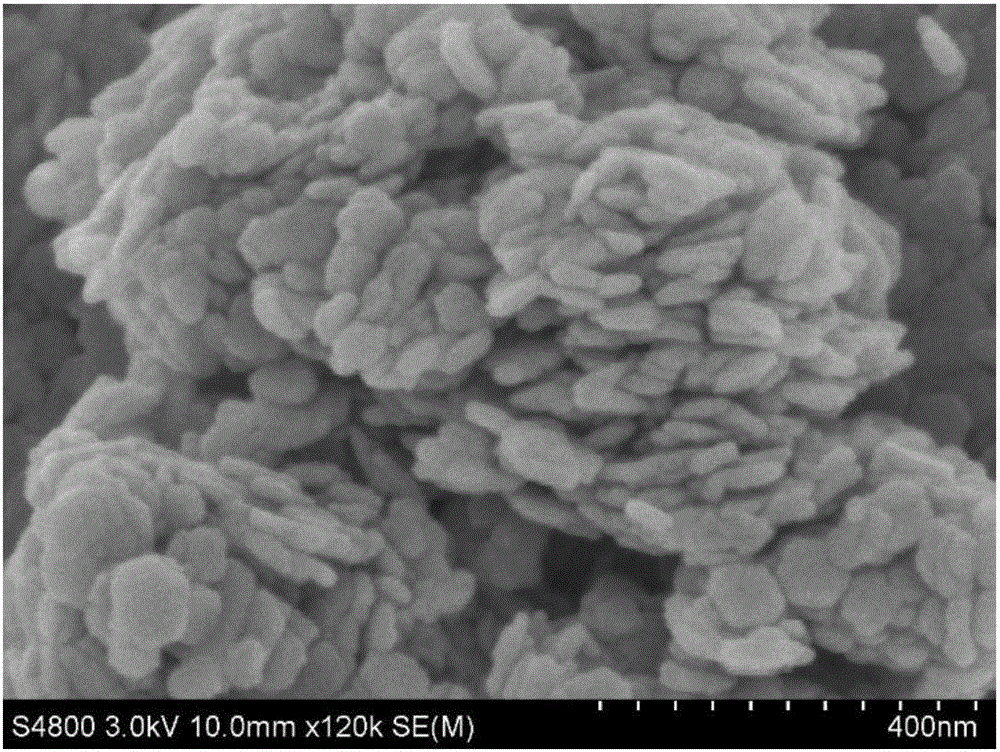

Preparation method of hexagonal lamellar SnS2 sodium-ion battery anode material

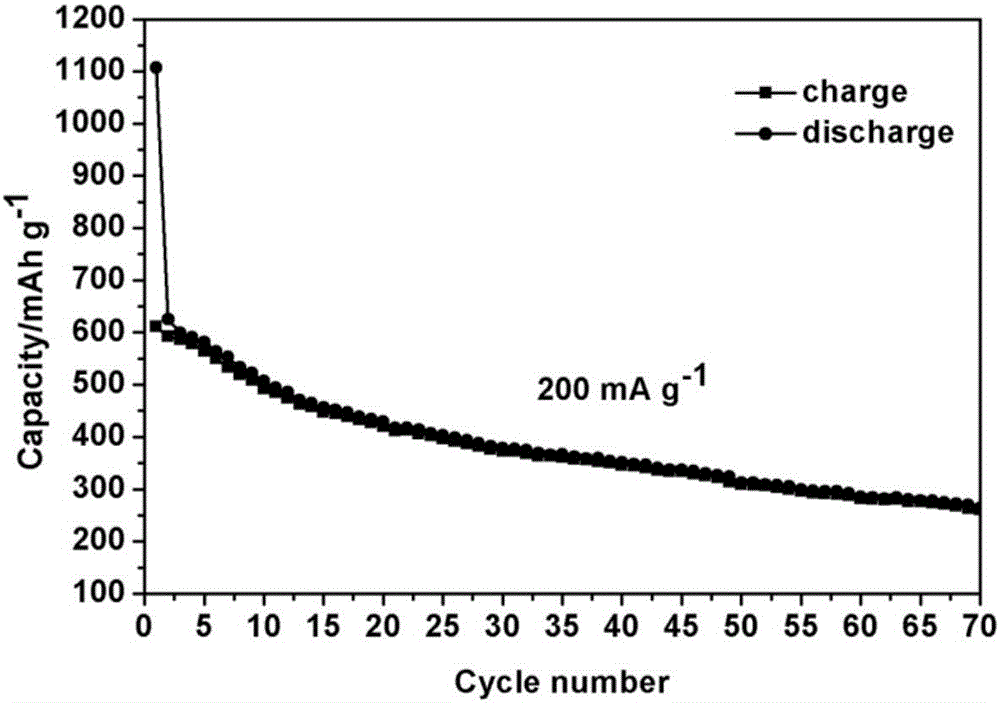

A technology of sodium ion battery and negative electrode material, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of long reaction time of powder, difficult control of particle morphology, and easy occurrence of intermediate impurities, etc., and achieves short preparation cycle and excellent performance. Charge/discharge rate performance, the effect of strong crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A hexagonal lamellar SnS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0036] (1) Thioacetamide (CH 3 CSNH 2 ) was dissolved in deionized water, and the CH 3 CSNH 2 Stir until completely dissolved, and prepare solution A with a concentration of 0.5mol / L;

[0037] (2) Add hexadecylmethyltrimethylammonium bromide (CTAB) into solution A under the action of magnetic stirring until uniform suspension B is formed, ultrasonically disperse for 15-20 minutes to completely dissolve, and transparent and clear solution C is obtained;

[0038] (3) According to the element molar ratio n Sn :n S =1.0:1.2 tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in the transparent clear solution C, stir 10~15min under magnetic stirring condition and be mixed with solution D; The ratio of the molar concentration of Sn ion in the mixed solution D and the molar concentration of hexadecylmethyltrimethylammoni...

Embodiment 2

[0045] A hexagonal lamellar SnS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0046] (1) Thioacetamide (CH 3 CSNH 2 ) was dissolved in deionized water, and the CH 3 CSNH 2 Stir until completely dissolved, and prepare solution A with a concentration of 0.9mol / L;

[0047] (2) Add hexadecylmethyltrimethylammonium bromide (CTAB) into solution A under the action of magnetic stirring until uniform suspension B is formed, ultrasonically disperse for 15-20 minutes to completely dissolve, and transparent and clear solution C is obtained;

[0048] (3) According to the element molar ratio n Sn :n S =1.0:2.0 tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in the transparent clear solution C, stir 10~15min under magnetic stirring condition and be mixed with solution D; The ratio of the molar concentration of Sn ion in the mixed solution D and the molar concentration of hexadecylmethyltrimethylammoni...

Embodiment 3

[0053] A hexagonal lamellar SnS 2 A preparation method for a negative electrode material for a sodium ion battery, comprising the following steps:

[0054] (1) Thioacetamide (CH 3 CSNH 2 ) was dissolved in deionized water, and the CH 3 CSNH 2 Stir until completely dissolved, and prepare solution A with a concentration of 1.2mol / L;

[0055] (2) Add hexadecylmethyltrimethylammonium bromide (CTAB) into solution A under the action of magnetic stirring until uniform suspension B is formed, ultrasonically disperse for 15-20 minutes to completely dissolve, and transparent and clear solution C is obtained;

[0056] (3) According to the element molar ratio n Sn :n S =1.0:2.4 tin tetrachloride pentahydrate (SnCl 4 ·5H 2 O) be dissolved in the transparent clear solution C, stir 10~15min under magnetic stirring condition and be mixed with solution D; The ratio of the molar concentration of Sn ion in the mixed solution D and the molar concentration of hexadecylmethyltrimethylammoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com