Two-phase biological deodorization method and two-phase biological deodorization device

A biological deodorization and biological reaction technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of no obvious division of the device, poor degradation effect, mutual interference, etc., to avoid competitive inhibition, Promote synergy, strong synergy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a specific method for biological deodorization of malodorous gases, comprising the following steps:

[0051] 1) Humidification treatment

[0052] Utilize the nutrient solution to humidify the malodorous gas spray; the specific composition of the nutrient solution is (mass fraction): KH 2 PO 4 2%, MgSO 4 ﹒ 7H 2 O 0.05%, NH 4 Cl 0.01%, FeSO 4 ·7H 2 O 0.001%, CaCl 2 0.02%, the balance is water. Its pH is 5.8-6.2.

[0053] 2) acid treatment

[0054] Then acidophilic bacteria and fungi are used to acidify the humidified malodorous gas to degrade sulfur-containing and hydrophobic and refractory gaseous substances in the malodorous gas.

[0055] Wherein, the acidophilic bacteria are selected from T.thiooxidans and T.ferrooxidans, and the ratio of the two is 60:40; the fungi are selected from the genus Penicillium, Geotrichum (Geotrichum) and Cladosporium (Cladosporium), the ratio of the three is 40:30:30; wherein, the addition amount of t...

Embodiment 2

[0073] Adopt the method identical with embodiment 1 to process malodorous gas, difference is only in:

[0074]1. The concentrations of hydrogen sulfide, ammonia and butyric acid in the malodorous gas before treatment are 50.54mg / m3 3 , 22.3mg / m 3 , 25.71mg / m 3 ;

[0075] 2. The treatment time of humidification treatment, acid treatment and neutral treatment is 10s, 25s and 25s respectively, totaling 60s;

[0076] The concentrations of hydrogen sulfide, ammonia, and butyric acid in the exhaust gas from the gas port were detected to be 0.01mg / m 3 , 0.08mg / m 3 and 0mg / m 3 , lower than the discharge standard of odor pollutants, the removal rates are 99.98%, 99.64% and 100% respectively.

Embodiment 3

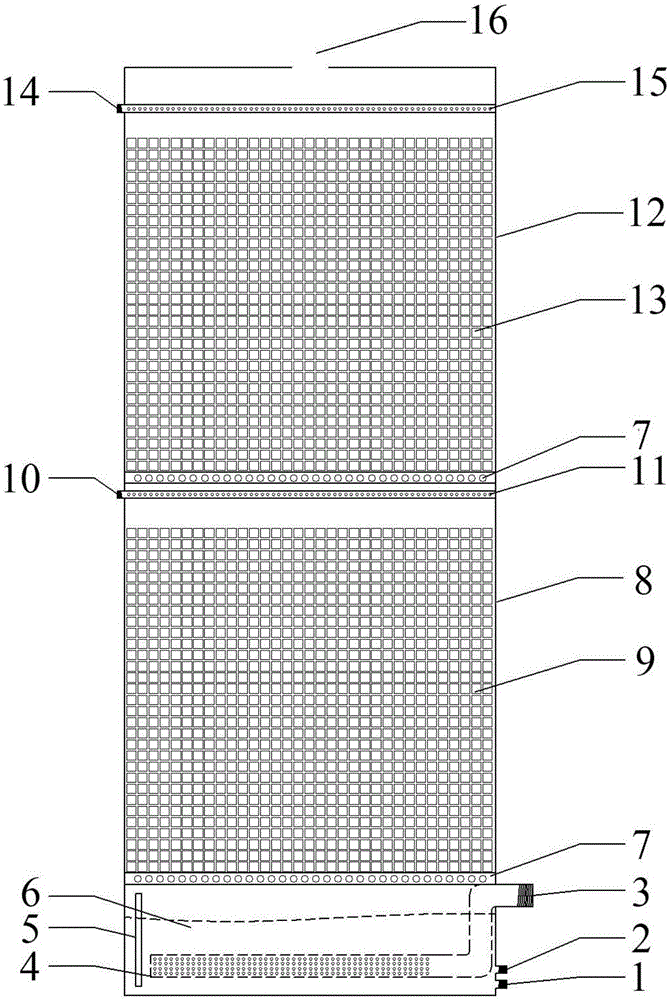

[0081] This embodiment provides a deodorizing device that can realize the deodorizing method of the above-mentioned embodiment 1 and 2, please refer to figure 1 . The material of the deodorizing device is plexiglass, the basic structure is cylindrical, the diameter is 90mm, and the total volume is 5L. It is divided into gas humidification zone 6 and acid phase biological reaction zone by two porous gas distribution plates 7 in turn. 8 and 12 three parts of the neutral phase biological reaction zone. A liquid discharge port 1 is opened on the side wall of the lower part of the gas humidification area 6, a liquid supply port 2 is opened above the liquid discharge port, an air inlet 3 is opened above the liquid supply port, and an aeration pipe is laid at the bottom of the gas humidification area 4. The nozzle is connected to the air inlet; a water level observation port 5 is opened on the side wall of the gas humidification area 6 .

[0082] Inert acidic phase composite packin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com