Graphite-like g-C3N4/montmorillonite composite material and application thereof in cellulose hydrolysis

A technology of composite materials and montmorillonite, which is applied in the field of cellulose hydrolysis to produce reducing sugars, can solve problems such as unseen research reports, and achieve the effects of simple operation, good catalytic performance, and large sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

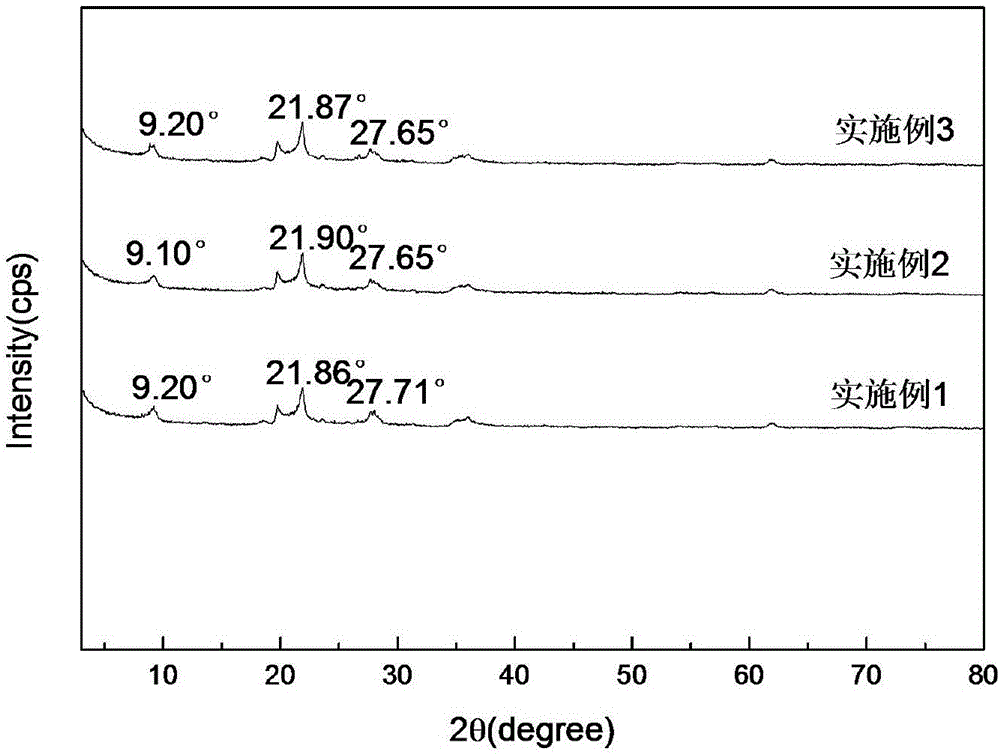

[0042] Take by weighing 2g montmorillonite (the cation exchange capacity CEC of montmorillonite used is 93.94mmol / 100g) is placed in the beaker, pours into 50ml deionized water, stirs 10min, then adds 0.16g liquid cyanamide (1CEC), in Stir at 25°C for 1 hour for exchange adsorption, then centrifuge the product in a centrifuge and wash it with water for several times, then put the viscous solid in an evaporating dish, dry it in a constant temperature drying oven, and grind the dried white solid into powder Then pour it into the quartz tank, then put the quartz tank into the quartz sleeve of the single tube furnace, and keep the sample in the constant temperature zone. After sealing, pass nitrogen gas for 1 h to remove the air in the quartz sleeve. The tube furnace raised the temperature from 20°C to 500°C at a rate of 10°C / min, kept the temperature for 4 hours, and cooled naturally after the calcination to obtain the product g-C 3 N 4 / montmorillonite composite material, deno...

Embodiment 2

[0044] Change the quality of liquid cyanamide in embodiment 1 into 0.32g (2CEC), other steps are as embodiment 1, obtain product and be recorded as material 2, composite material XRD result is as follows figure 1 shown.

Embodiment 3

[0046] Change the quality of liquid cyanamide in Example 1 to 0.48g (3CEC), and other steps are as in Example 1, and the product obtained is recorded as material 3. The XRD results of composite materials are as follows: figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com