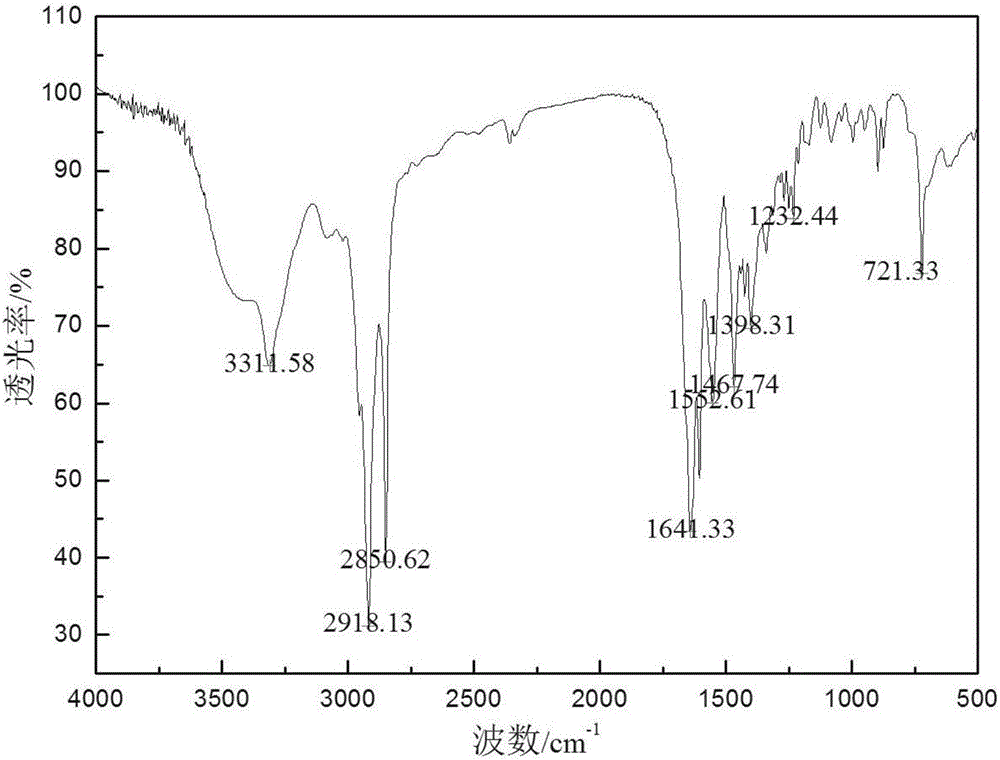

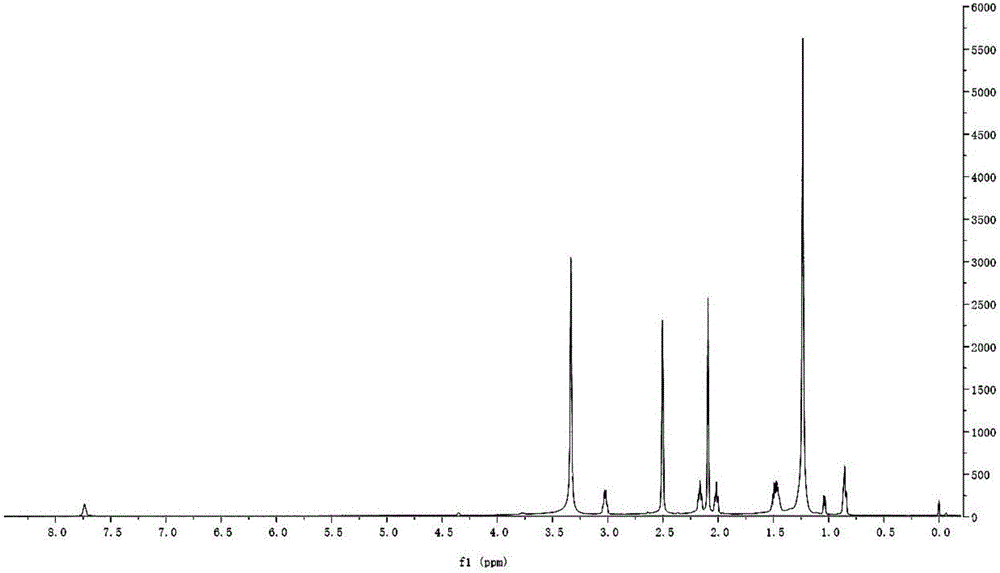

Glycine betaine-type ampholytic surfactant and preparation method thereof

A technology of surfactant and betaine, which is applied in the field of betaine-type amphoteric surfactant and its preparation, can solve the problems of low active substance content, increased production cost, difficulty in reducing acid value, etc., achieve mild performance, improve production The effect of low production rate and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of above-mentioned betaine type amphoteric surfactant comprises the following steps:

[0036] 1) Amidation reaction: Melt natural oil acid, add 3-dimethylaminopropylamine, mix well, add catalyst to carry out

[0037] For amidation reaction, add 4A molecular sieve after reacting for 5-7 hours, continue the reaction, and remove unreacted

[0038] 3-dimethylaminopropylamine and natural oleic acid to obtain alkyl amidopropyl dimethyl tertiary amine;

[0039] 2) Quaternization reaction: Add alkyl amidopropyl dimethyl tertiary amine and sodium chloroacetate to the reactor, add water until the sodium chloroacetate dissolves

[0040] solution is complete, then add isopropanol, adjust the pH value to 7-8, carry out quaternization reaction, and remove isopropanol after the reaction is completed.

[0041] propanol, water and unreacted sodium chloroacetate to obtain a betaine-type amphoteric surfactant.

[0042] Preferably, the structural formula of the na...

Embodiment 1

[0052] A kind of preparation method of betaine type amphoteric surfactant comprises the following steps:

[0053] 1) Amidation reaction: Add 25.6475g of palmitic acid into a three-necked flask equipped with a reflux condenser, raise the temperature to 80°C to slowly melt the palmitic acid, and then add 10.728g of 3-dimethylaminopropylamine dropwise while stirring (The molar ratio of palmitic acid to 3-dimethylaminopropylamine is 1:1.05), after 30 minutes of dripping, 0.177g of KOH was added as a catalyst, and the temperature was raised to 160°C for amidation reaction. After 6 hours of reaction, 10g of 4A was added Molecular sieves, continue to react for 5h, after the completion of the reaction, first remove unreacted 3-dimethylaminopropylamine and by-product water in the crude product by distillation under reduced pressure, and then use 1% Na 2 CO 3 The solution was washed to remove unreacted palmitic acid to obtain palmitoamidopropyl dimethyl tertiary amine with a yield of 9...

Embodiment 2

[0060] A kind of preparation method of betaine type amphoteric surfactant comprises the following steps:

[0061] 1) Amidation reaction: Add 22.84g of myristic acid into a three-necked flask equipped with a reflux condenser, raise the temperature to 80°C to slowly melt the myristic acid, and then add 10.73g of 3-dimethylamine dropwise while stirring Dimethylaminopropylamine (the molar ratio of myristic acid to 3-dimethylaminopropylamine is 1:1.05), drop it in 30 minutes, then add 0.17g of NaOH as a catalyst, raise the temperature to 160°C, and carry out amidation reaction. After 6 hours of reaction, add 10g of 4A molecular sieves, continue to react for 5h, after the completion of the reaction, first remove the unreacted 3-dimethylaminopropylamine and by-product water in the crude product by distillation under reduced pressure, and then use 1% Na 2 CO 3 The solution was washed to remove unreacted myristic acid to obtain myristamidopropyldimethyl tertiary amine with a yield of ...

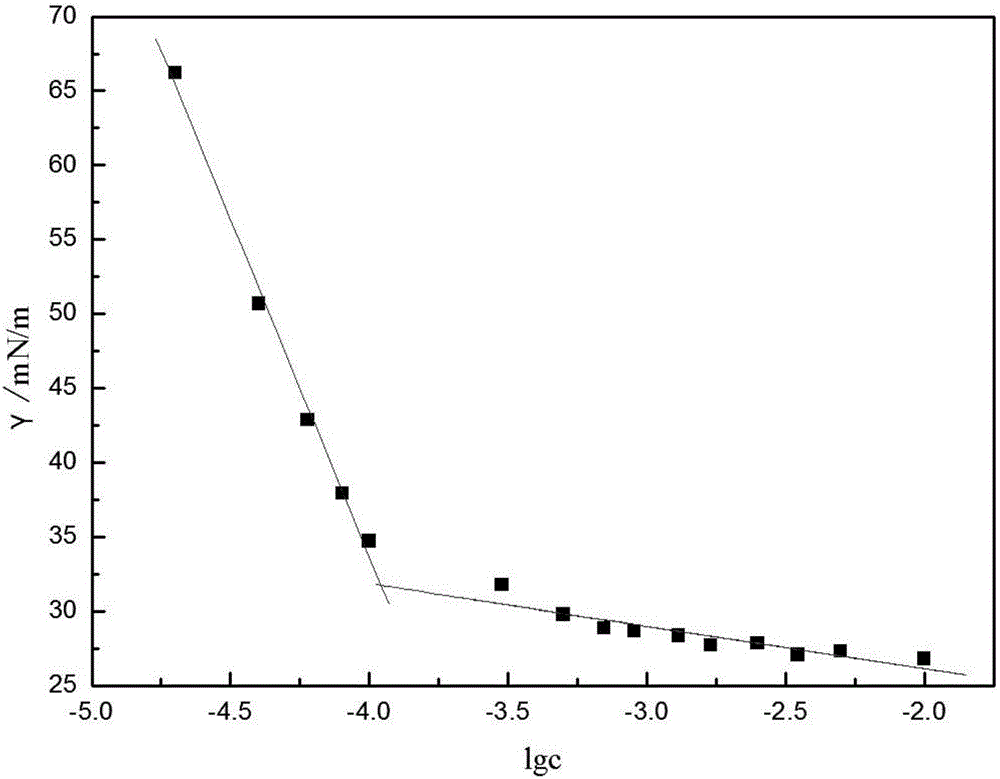

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical micelle concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com