Catalyst for directly dehydrogenating propane to prepare propylene as well as preparation and application of catalyst

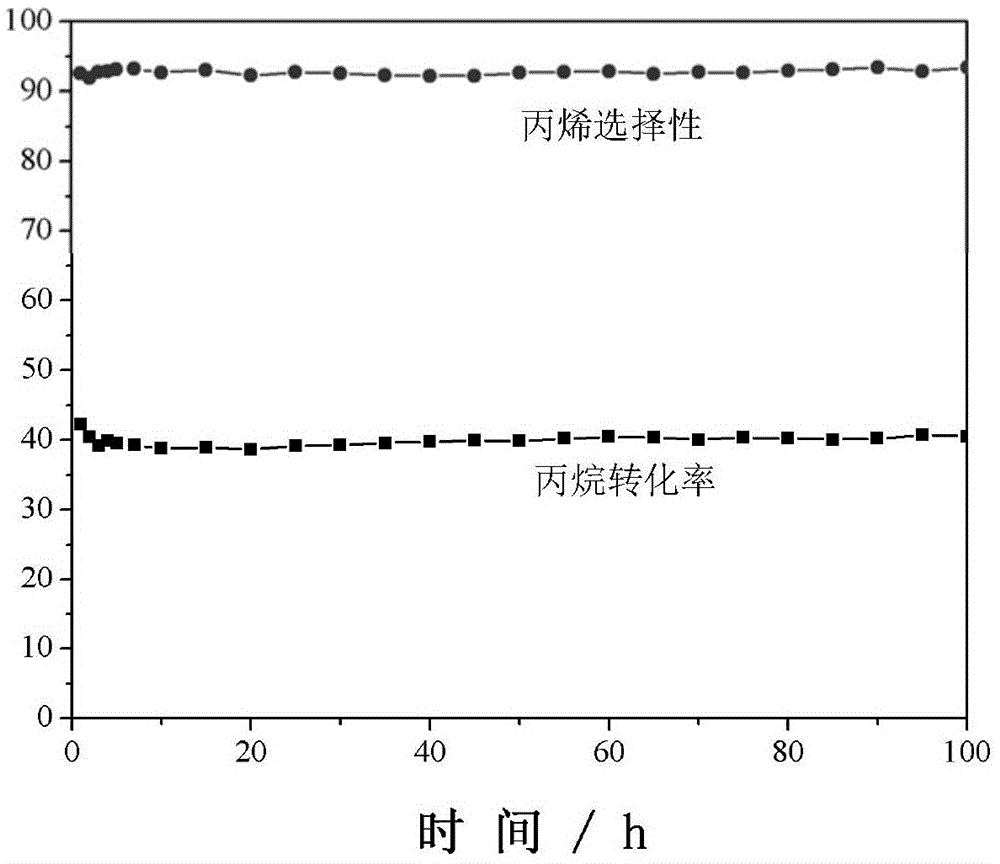

A catalyst and dehydrogenation technology, applied in molecular sieve catalysts, physical/chemical process catalysts, hydrocarbons, etc., can solve the problem of easy coking of catalysts, and achieve carbon deposition inhibition, good propylene activity and propylene selectivity, and less coking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

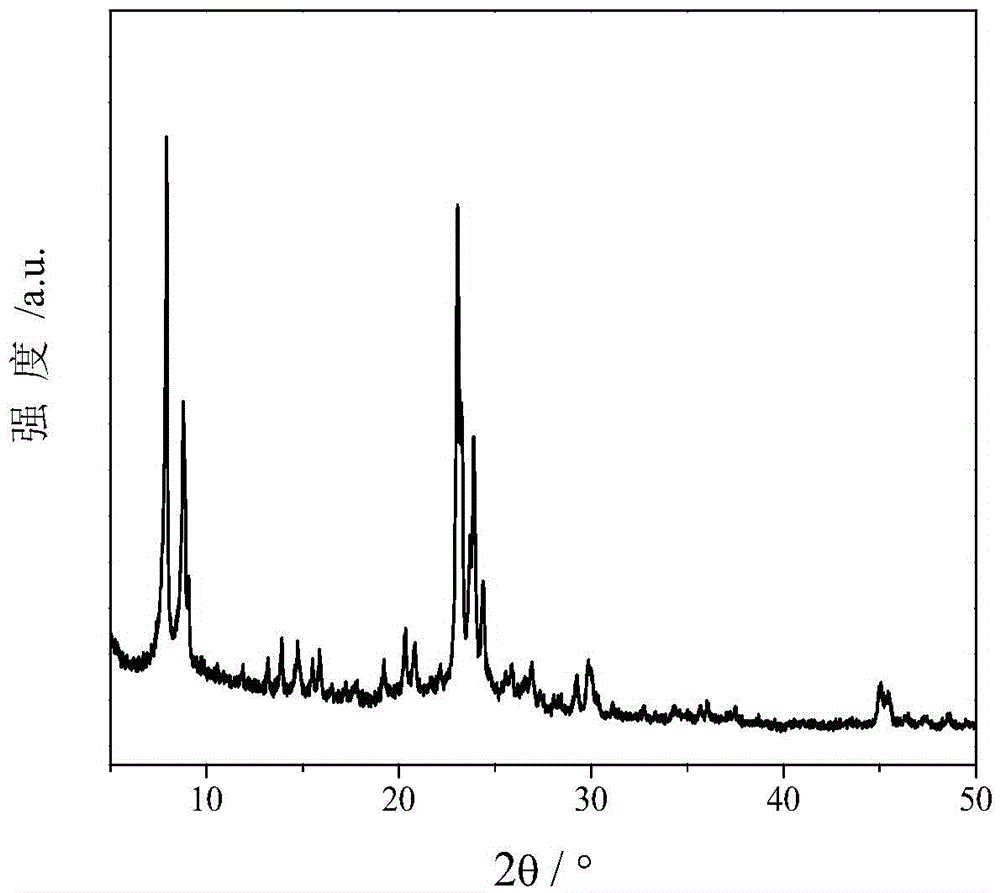

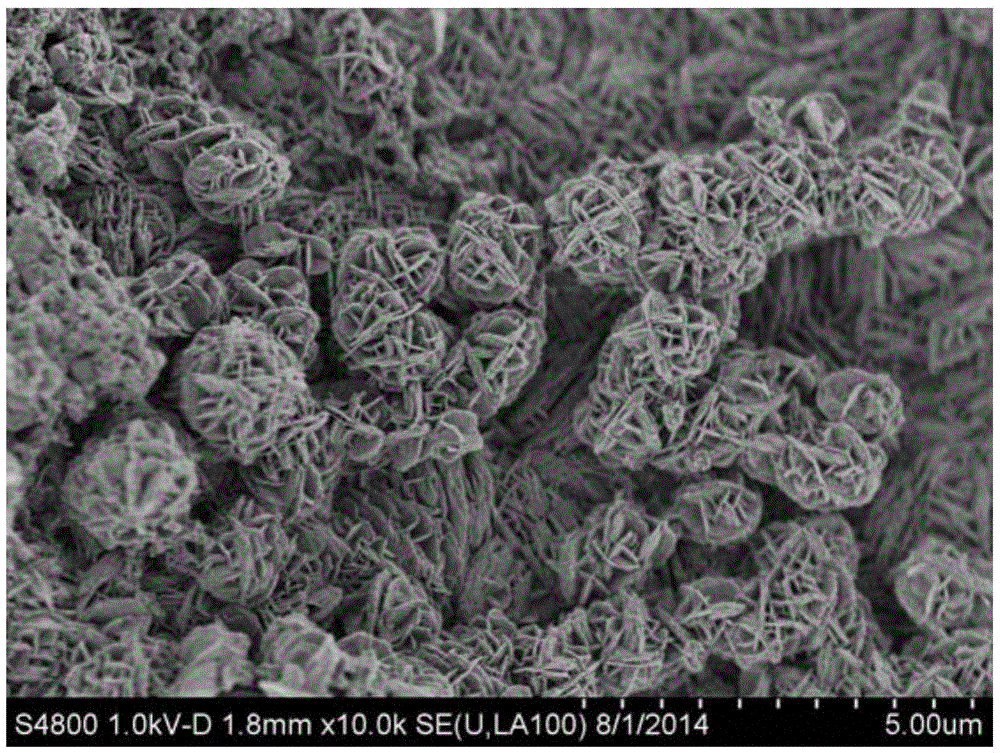

[0040] Preparation of nanosheet MFI structure molecular sieve: NaOH, aluminum sulfate, water glass, template C 22-6-6 Br 2 、H 2 SO 4 and distilled water with 30Na 2 O:1Al 2 o 3 :100SiO2 2 :8C 22-6-6 Br 2 :18H 2 SO 4 :4000H 2 The molar ratio of O (where "Na 2 The amount of O" refers to NaOH in Na 2 O amount) stirring and mixing, obtained molecular sieve gel. Put the gel in a high-pressure reactor equipped with a polytetrafluoro inner layer, and crystallize at 140-160°C for 120h. After the crystallization reaction is completed, the product is washed with distilled water, dried at 120° C., and then calcined at 550° C. for 6 hours to obtain a molecular sieve with nanosheet MFI structure.

[0041] Catalyst preparation: Dissolve 0.082g of chloroplatinic acid, 0.1753g of magnesium nitrate and 0.2730g of zinc nitrate in 50mL of water to prepare a mixed solution, put 6g of the above-mentioned nano-sheet MFI structure molecular sieve into it for 12h, dry at 120°C, and then...

Embodiment 2

[0045] Preparation of nanosheet MFI structure molecular sieves: NaOH, aluminum sulfate, white carbon black, template C 18-6-6 Br 2 、H 2 SO 4 and distilled water with 28Na 2 O:1Al 2 o 3 :300SiO2 2 :8C 18-6-6 Br 2 :18H 2 SO 4 :4000H 2 The molar ratio of O was stirred and mixed to obtain a molecular sieve gel. Put the gel in a high-pressure reactor equipped with a polytetrafluoro inner layer, and crystallize at 140-160°C for 120h. After the crystallization reaction is completed, the product is washed with distilled water, dried at 120° C., and then calcined at 550° C. for 12 hours to obtain a molecular sieve with nanosheet MFI structure.

[0046] Catalyst preparation: Dissolve 0.080g of chloroplatinic acid, 0.1351g of calcium nitrate and 0.2730g of zinc nitrate in 50mL of water to prepare a mixed solution, put 6g of the above-mentioned nano-sheet MFI structure molecular sieve into it for 12h, dry at 120°C, and then dry at 500°C Calcined for 12 hours to obtain molecul...

Embodiment 3

[0050] Preparation of nanosheet MFI structure molecular sieve: NaOH, aluminum sulfate, silica sol, template agent C 16-6-3 Br 2 、H 2 SO 4 and distilled water with 26Na 2 O:1Al 2 o 3 :500SiO2 2 :8C 16-6-3 Br 2 :18H 2 SO 4 :4000H 2 The molar ratio of O was stirred and mixed to obtain a molecular sieve gel. Put the gel in a high-pressure reactor equipped with a polytetrafluoro inner layer, and crystallize at 140-160°C for 120h. After the crystallization reaction is completed, the product is washed with distilled water, dried at 120° C., and then calcined at 550° C. for 6 hours to obtain a molecular sieve with nanosheet MFI structure.

[0051] Catalyst preparation: Dissolve 0.080g of chloroplatinic acid, 0.0812g of strontium nitrate and 0.1251g of zinc chloride in 50mL of water to prepare a mixed solution, put 6g of the above-mentioned nanosheet MFI structure molecular sieve into it, dip for 12h, dry at 120°C, and then Calcined at 550°C for 10h to obtain molecular sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com