Nano-porous energy absorbing material as well as preparation method and application thereof

A nanoporous, energy-absorbing technology, applied in the fields of applications, chemical instruments and methods, molecular sieves, and base-exchange compounds, etc., can solve problems such as the limitation of application range, the specific surface area of nanoporous materials and the limited adjustable range of solid-liquid interface characteristics, etc. , to achieve the effect of light weight, small thickness and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

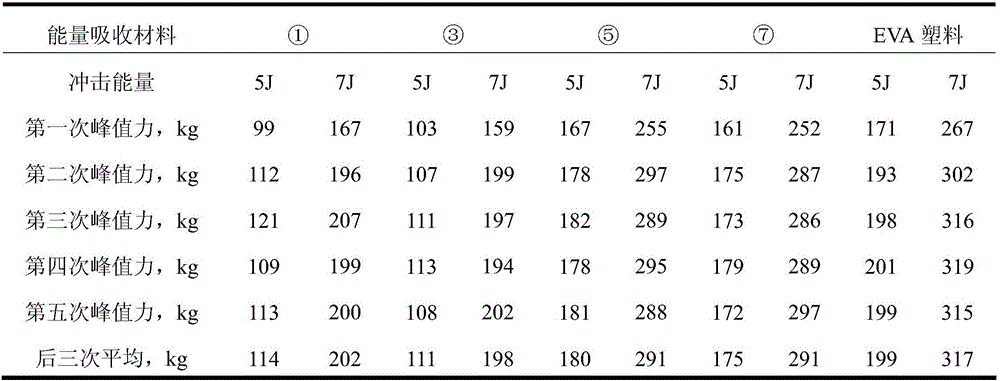

Examples

preparation example Construction

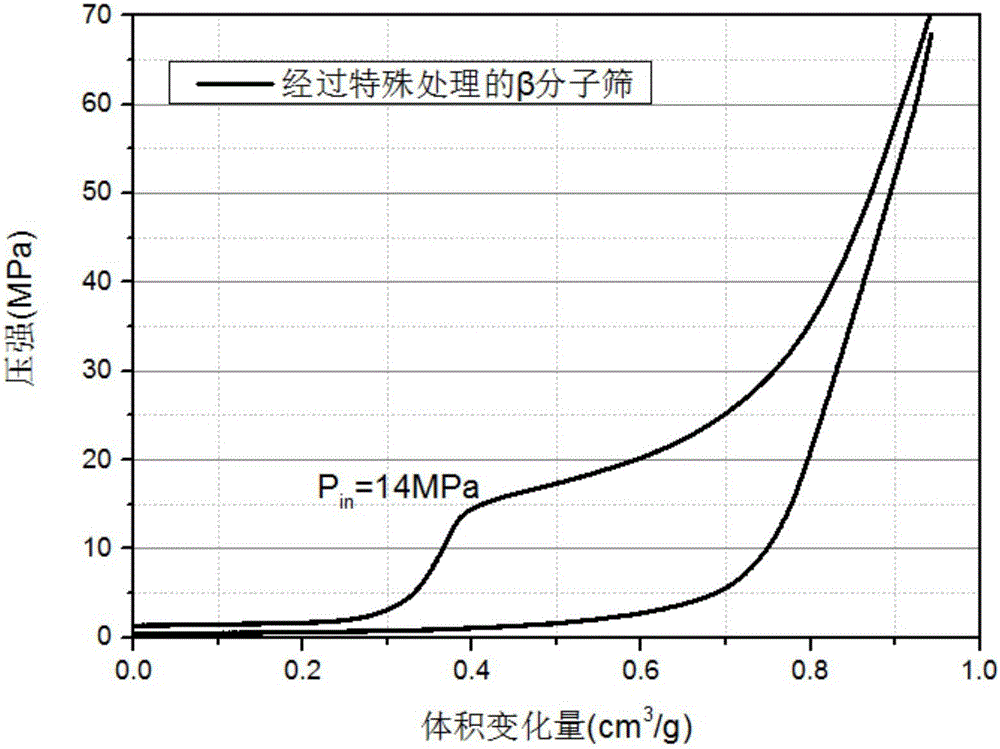

[0040] A kind of preparation method of nanoporous energy absorbing material

[0041] Raw material preparation and purchase

[0042] 1. β molecular sieve: SiO 2 / Al 2 o 3 60, specific surface 600m 2 / g, pore volume 0.47ml / g, purchased from Catalyst Factory of Nankai University, synthesized under hydrothermal conditions and removed template agent by high temperature roasting;

[0043] 2. Chlorotrimethylsilane: CP grade (≥98.0%), 100ml / bottle, purchased from Sinopharm Chemical Reagent Co., Ltd.;

[0044] 3. The preparation method of special treatment molecular sieve, the specific steps are as follows:

[0045] 1) Weigh 50g of β molecular sieve and add it into 300ml of deionized water, stir for 1 hour to form a uniform mixture, transfer it to a 500ml hydrothermal reaction kettle, put it into a blast drying oven, set the temperature at 120°C, and control the pressure at 0.2 Hydrothermal treatment is carried out within MPa, and the treatment time is 6h;

[0046] 2) After the ...

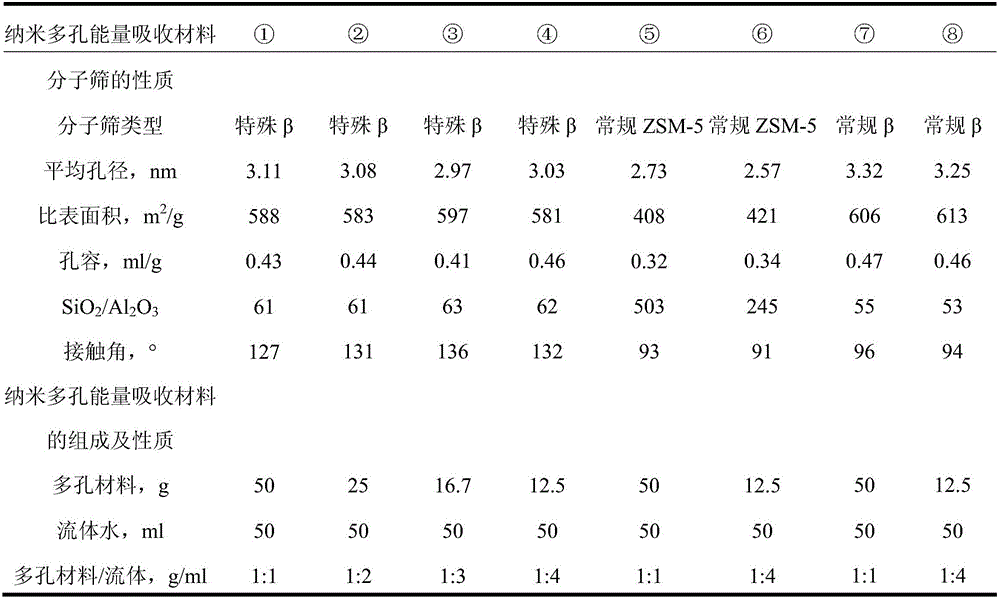

Embodiment 1

[0049] The preparation method of nanoporous energy absorbing material ①, the specific steps are as follows:

[0050] 1) Weigh 50ml of deionized water fluid and add it into a beaker, and add the above-mentioned specially treated β molecular sieve 50g and 2.5g polyethylene glycol dispersant to form a mixed solution while stirring;

[0051] 2) Heat the above mixed solution to boiling while stirring, add 2.5g of potassium hydroxide additive to the boiling mixed solution, react for 0.5h, and then naturally cool to room temperature to obtain the nanoporous energy absorbing material ①.

Embodiment 2

[0053] The preparation method of nanoporous energy absorbing material ②, the specific steps are as follows:

[0054] 1) Weigh 50ml of deionized water fluid and add it into a beaker, and add the above-mentioned specially treated β molecular sieve 25g and 2.5g polyethylene glycol dispersant to form a mixed solution while stirring;

[0055] 2) Heat the above mixed solution to boiling while stirring, add 2.5g of potassium hydroxide additive to the boiling mixed solution, react for 0.5h and then cool it down to room temperature naturally to obtain the nanoporous energy absorbing material ②.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com